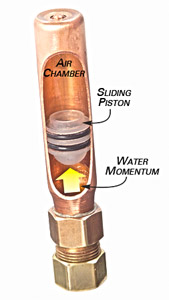

I understand that a knock arrestor has a piston and O rings inside the chamber that compress the air above it to arrest the sudden spike in water pressure. If you remove the arrestor and push on the bottom of that piston, should you be able to feel it move inward and then return? Would that be a valid check to see if it is still working? I realize you could also maybe hear if it is no good anymore, but I'd like to know if this is also a test.

PS this would be in a home laundry..........about a $11 to $20 item.

PS this would be in a home laundry..........about a $11 to $20 item.