Pmac16

New Member

Hi all,

Here's my situation. I have a current sprinkler system from the existing homeowner that was set up to pull water from a lake.

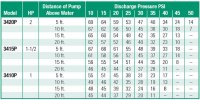

The homeowner took the pump so I have purchased a simer 3415p as a replacement.

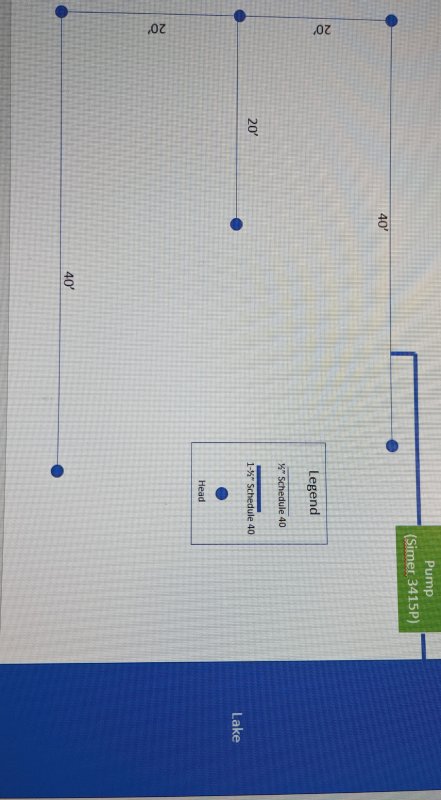

The setup (picture attached) is 1/2" schedule 40 pvc, single zone, with 6 Hunter PGP Ultra heads. I'm not sure how he made this work and expect to have issues due to pressure loss resulting from the pipe size. What's the simplest fix? A)different pump, B) different heads, C)run 1.5" across the middle creating smaller runs of .5"? Is there any scenario in which I can make the current piping work?

Here's my situation. I have a current sprinkler system from the existing homeowner that was set up to pull water from a lake.

The homeowner took the pump so I have purchased a simer 3415p as a replacement.

The setup (picture attached) is 1/2" schedule 40 pvc, single zone, with 6 Hunter PGP Ultra heads. I'm not sure how he made this work and expect to have issues due to pressure loss resulting from the pipe size. What's the simplest fix? A)different pump, B) different heads, C)run 1.5" across the middle creating smaller runs of .5"? Is there any scenario in which I can make the current piping work?