Hello everyone & thanks again for help with my softener install about 2 years ago. All has been working great until about 2 months ago when after regeneration there was a lot of air in the water lines in the morning. It's gone after the first flush of the toilets. Also the brine tank was not filling but it was drawing. I read everything I could find & decided to check all fittings first, no change. Then I cleaned everything in the injector drain assembly (saw no dirt or debris), after that the brine tank was filling and drawing but still air in the lines. I left it like this for about a month with no change & still air in the lines after regeneration. I then replaced the air check, no change. I eliminated the float assembly, connected directly to the air check, still no change. I then disconnected the air check & held my finger over the brine draw/refill tube & when the suction built up it sounded like it was drawing air in around the valve body somewhere. Now I'm at a loss. One thing that happened at the same time this all started was Fire Hydrant flushing not sure if this could be the cause but thought it was worth a mention. Any ideas/advice would be appreciated!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fleck 5600sxt Air in water lines after regeneration

- Thread starter SS12

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Sponsor

Paid Advertisement

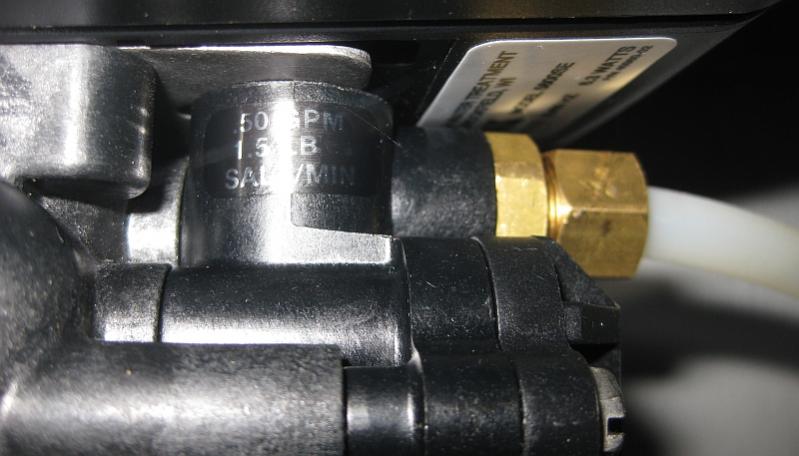

Thank You, I will give that a try tonight as soon as I get home from work and post the results. Sounds like a good idea I've never heard of that but it should be easy to see with shaving cream.You could use some aerosol shaving cream around the brine line junctions and BLFC and injector area during brine draw. You will see any area of suction. That area of the softener is to the right of this photo:

Okay I tried the shaving cream in the recommended areas and saw nothing being drawn in. I then checked the injector cap screws & they were tight. I loosened one of the screws & the sucking sound got worse, it didn't sound like I created a new leak but instead made the existing one worse. I guess at this point I'll order new o rings. Also I noticed during the bf that there was intermittent sputtering of the fill water, not sure if this is related?

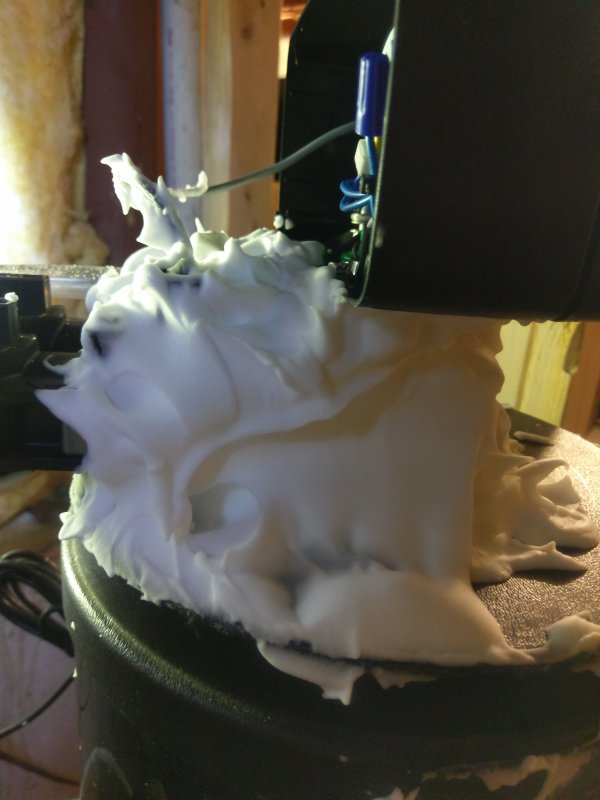

I will try this again tonight with a thin coating. I think I put too much shaving cream on the parts. The cream expands quite a bit & after thinking about it I guess there could have been an air pocket underneath I couldn't see. I started with a small amount but when I didn't see any getting drawn in I covered the whole head.

Yep... sure looks like you have it covered. The foam like that is often recommended to find vacuum leaks on the pipe joints on a single-pipe shallow where a jet pump is sucking water from maybe 20 ft or so below the pump.

Sorry it did not uncover your leak.

Sorry it did not uncover your leak.

ditttohead

Water systems designer, R&D

Leaks on the brine are very easy to find. Put the system into refill and kink the brine line. This will pressurize the line and components.

Sorry for the late reply, I was tied up yesterday. I'm not sure about kinking the line it's a semi hard (polyethylene?) plastic I think it will get damaged, maybe just plug the end? Will this cause the fill water to come out where the air leak is? I was also going to take the injector assembly apart again & check all o rings, the first time around I was just looking for some type of blockage since the brine tank wasn't filling. Didn't pay much attention to the o rings since the unit is so new. I lubed them and reassembled. I also assumed the air leak was either the air check, float assy, fittings in the brine tank or brine line. I probably won't be able to get to it until Saturday, but I will post back.Leaks on the brine are very easy to find. Put the system into refill and kink the brine line. This will pressurize the line and components.

How about lifting the float? You could probably make yourself an L-shaped tool to go into the brine well and lift the float. Maybe even a piece of cord with both ends out of the brine well could be used to lift the float. A clamp etc could hold the cord ends during the test.Sorry for the late reply, I was tied up yesterday. I'm not sure about kinking the line it's a semi hard (polyethylene?) plastic I think it will get damaged, maybe just plug the end? Will this cause the fill water to come out where the air leak is?

Last edited:

Okay...After 10 days I finally had time to get to the softener! I replaced all o rings in the injector assembly (all of the originals look fine). I also took dittoheads's advice and stopped the flow during brine fill and everything came to a dead stop no noise no leaks. I still have air in the lines after regeneration and I'm out of ideas. I just finished testing it now but I'm going to manually start a regeneration and let it go through it's paces without me skipping ahead to brine draw. I don't know if that will make a difference but can't hurt. I won't be able to do this until later tonight because my wife and mother are doing laundry and they don't want to hear "don't run the water for a couple of hours" ever again. I will post back the results. I'm a commercial painter by trade and work in a building downtown Chicago, the building plumber has over 40 yrs experience but not much with softeners and told me "some things are just a mystery" I'm starting to believe him ha ha...

If the air check is letting air into the brine line, I think you could see that appear maybe in the latter 3/4 of the brine draw time. Your brine line is translucent enough if lighted right, I think.

If air is coming in from where the brine line connects to the float assembly, I think you could see bubbles early in the brine draw.

My comments are not based on experience.

If air is coming in from where the brine line connects to the float assembly, I think you could see bubbles early in the brine draw.

My comments are not based on experience.

The brine should be gone about 25% into the BD cycle. So maybe for 60 minute cycle, brine is drawn in about the first 15 minutes. The last 45 there is a vacuum in the brine line.I see no bubbles in the draw until the very end when all the brine is gone. But I continue to see drops of water trying to make their way up.

I would think that the brine line should still have mostly liquid in it during that time. I haven't actually watched to see. I am suspecting that your new air check leaks air in.

I have to think about that. There is no water left and I see bubbles and water drops trying to make their way up so maybe their is a leak somewhere in the brine tank but I eliminated the float assembly and connected directly to the air check

I think I forgot to mention that the air check is new I just bought it, so I,m guessing maybe my connections. I was very careful not to over tighten & could not draw air through by mouth. But if it continues to draw I must have a bad connection

Okay I give up for tonight. I checked all fittings ran it... still the same. One Question should there be water still going to drain after brine draw is complete and air check engages? Water kept running to drain until brine draw cycle (60min) was complete. Just wondering if this is normal. Tomorrow I'm going to connect directly to the air check tube from the top of the brine tank so that I can eliminate the elbow that brings it in from the side & also be able to lift the air check up to see if it's leaking

Bannerman

Well-Known Member

The aircheck valve is a ball which floats in the brine when present and seats into the suction pickup opening when the liquid level reaches a height that the ball will no longer float. If there is any grit or debris between the ball and the seat, air will make it past which will result in air being drawn into the resin tank and the issues you report.

The Brine Draw cycle is actually two functions which are combined into one setting often 60 minutes in duration. Rinse water will slowly flow through the injector which acts as a venturi. This then creates suction on the brine port to draw brine into the resin tank. Once the brine has all been drawn from the brine tank and the air check closes, rinse water will continue to flow thereby pushing the brine in the resin tank through the resin bed and finally out to drain. With a 60 minute BD cycle, the air check should be closed within 15 minutes so the remaining 45+ minutes is a Slow Rinse cycle.

The Brine Draw cycle is actually two functions which are combined into one setting often 60 minutes in duration. Rinse water will slowly flow through the injector which acts as a venturi. This then creates suction on the brine port to draw brine into the resin tank. Once the brine has all been drawn from the brine tank and the air check closes, rinse water will continue to flow thereby pushing the brine in the resin tank through the resin bed and finally out to drain. With a 60 minute BD cycle, the air check should be closed within 15 minutes so the remaining 45+ minutes is a Slow Rinse cycle.

ditttohead

Water systems designer, R&D

Here is the chart that shows how much water is drawn and how much flows once the brine tank is empty. Since it uses venture injection the system requires some water to cause the draw. If you look at the charts, these are some highly efficient venturi's. https://view.publitas.com/impact-water-products/2018-catalog-final/page/78-79

Similar threads

- Replies

- 0

- Views

- 272

- Replies

- 11

- Views

- 400

- Replies

- 2

- Views

- 99

- Replies

- 1

- Views

- 75