dwvpuzzled

New Member

I really appreciate this forum, and I usually find the answers I'm looking for by searching the forums so I never have had to post before now.

I'm remodeling a bathroom, and replacing the old leaking shower stall with a freestanding tub and a rainfall shower combo. The existing drain has to be moved a few inches to become the new tub drain, so it will be replaced with a 2" ABS P-Trap/Line, but will be fairly close to how the existing drain is situated (see photos).

I want to add a linear drain that will be situated approximately as shown in the photos to drain water that falls outside the freestanding tub when it is used with the ceiling mounted rainfall shower head, and I need to tie into the DWV line (floor will have appropriate slope to linear drain).

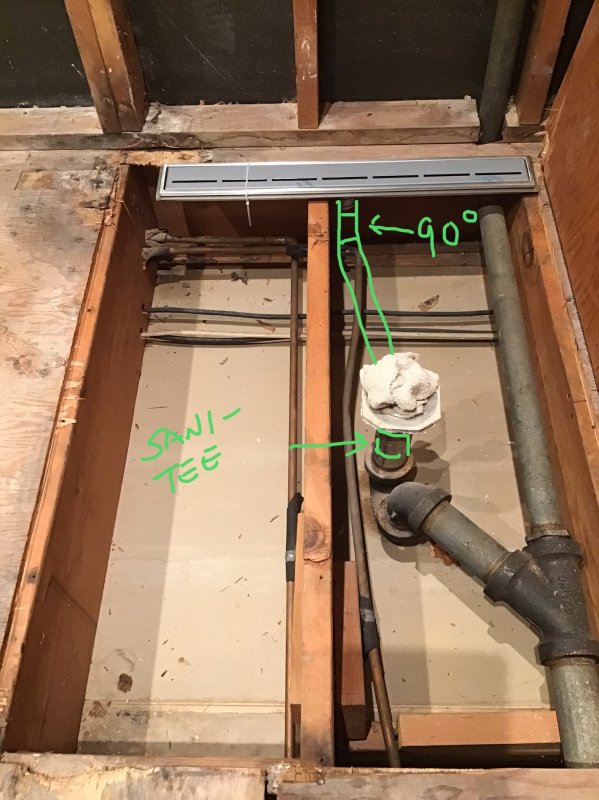

Long story short - a licensed plumber was working at my neighbors, was quite friendly, and I asked him if I could get his advice on my project and how to add the linear drain. He was nice enough to come over and take a look, and said to do it as shown in the first marked up photo. To run both drains into a single P-Trap, and tie into the existing DWV line just before the Wye. Sounded easy...

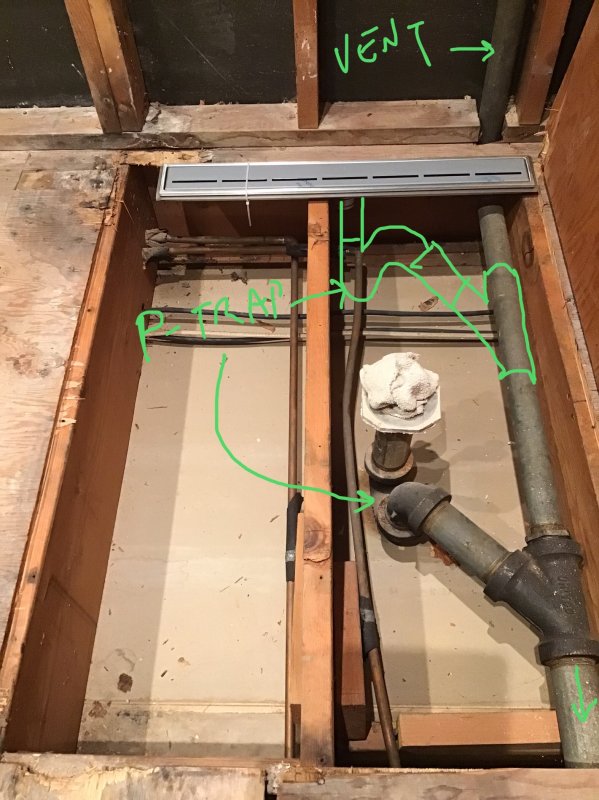

However, though this arrangement would likely work fine for the shower application, the physics for a tub usage worry me. I would be concerned that if a full tub was drained, that it could potentially backflow out of the linear drain. It seems safer to have separate P-Traps for the tub and linear drain, and tie them into the line as shown in final marked up photo.

Does this work? I thought I read that two P-Traps can't share a vent because one might get sucked dry by the other, but I've seen similar DWV layouts so I'm a little confused. Help and advice is very much appreciated. Thanks!

I'm remodeling a bathroom, and replacing the old leaking shower stall with a freestanding tub and a rainfall shower combo. The existing drain has to be moved a few inches to become the new tub drain, so it will be replaced with a 2" ABS P-Trap/Line, but will be fairly close to how the existing drain is situated (see photos).

I want to add a linear drain that will be situated approximately as shown in the photos to drain water that falls outside the freestanding tub when it is used with the ceiling mounted rainfall shower head, and I need to tie into the DWV line (floor will have appropriate slope to linear drain).

Long story short - a licensed plumber was working at my neighbors, was quite friendly, and I asked him if I could get his advice on my project and how to add the linear drain. He was nice enough to come over and take a look, and said to do it as shown in the first marked up photo. To run both drains into a single P-Trap, and tie into the existing DWV line just before the Wye. Sounded easy...

However, though this arrangement would likely work fine for the shower application, the physics for a tub usage worry me. I would be concerned that if a full tub was drained, that it could potentially backflow out of the linear drain. It seems safer to have separate P-Traps for the tub and linear drain, and tie them into the line as shown in final marked up photo.

Does this work? I thought I read that two P-Traps can't share a vent because one might get sucked dry by the other, but I've seen similar DWV layouts so I'm a little confused. Help and advice is very much appreciated. Thanks!