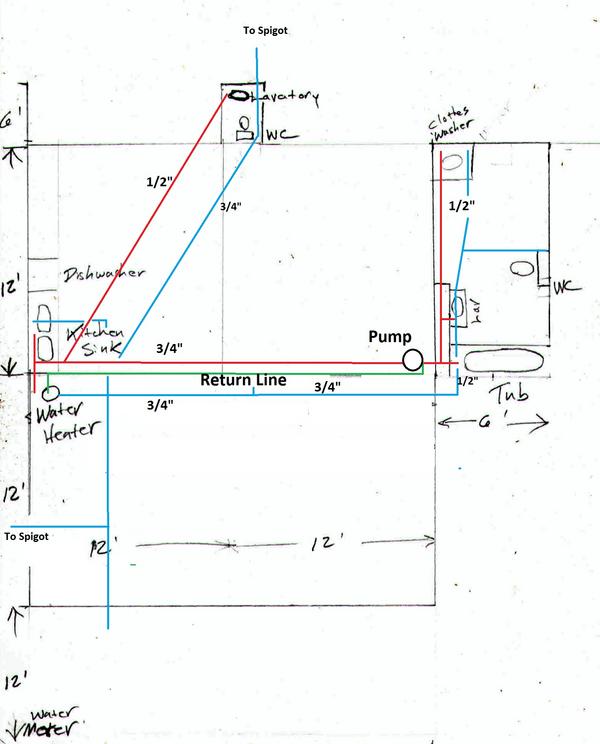

I've decided to definitely install a hot water recirculation system for the full bath. I may add the half into the loop, but I fear that there might not be a real advantage in doing so. I'm mainly curious about the pump I'm considering.

The supply and return line (green in the photo) will be 3/4" with a manifold in the plumbing wall. I want to use a switch operated pump instead of a timer or sensor-controlled one. I found this Grundfos model UP15-10BUC7 that I believe will work well. Here are the specs:

Max Pressure (PSI): 145

Temperature Range (F): 36°F - 230°F

Connection Size: 3/4"

Connection Type: Union

Max Flow (GPM): 6.6

Flow Range (GPM): 0-6.6

Head Range (ft.): 0-6.6

Max Head (Ft): 6.6

I'm planning on having the return line (green line in drawing below) enter the water heater at the bottom using a tee fitting on the drain bib. I believe this pump has a bleeder screw to allow one to purge the air from the system. I was planning on mounting it vertically in the pipe that goes down to the drain bib or if that's not a good idea then somewhere near the water heater.

Does anyone see any problems with this pump or layout?

EDIT: From doing a little research, it seems that having the return loop enter at the drain bib might not be a good idea and that the return loop should enter the water heater on the cold inlet side with a backflow preventer valve in place to keep it from entering the cold supply. Which is correct?

Here's a photo:

Here's a photo of my layout: