I've had a thread up here for a long time about needing to remodel. The house was built sometime in the 1940s and there were some DIY modifications from previous owners. It's a single floor home raised off the ground with wood floor and about a 2' to 3' crawl space underneath.

The main issue right now is that we want to switch the laundry room with the guest bathroom. To do this, we have to take down a couple small non-load bearing walls, move some of the plumbing over, and run new electrical (fortunately the main circuit box is in this area).

The temperature doesn't usually get below freezing here, but the last few years we've had colder weather than usual and it got down in the 20s and caused some pipes to rupture. The exterior walls seem to be 2x6s with a thin layer of plywood on the outside covered in house wrap. On the inside is 1/8" thick wood paneling. There is no insulation (something I intend to rectify when I remodel).

Building codes have changed so I know that PVC is no longer allowed above ground for water supply. I was recently told that in the past few years the code changed to require a check valve for the washing machine water supply lines. I'm trying to find the right type and size to use. The current supply lines are 3/4" PVC (for cold) and 3/4" CPVC (for hot).

Specific changes:

I need to move the supply lines for the current lavatory over less than a foot to work as the washing machine supply lines. This will bring them closer to the exterior wall (and exposed part under the house) so I will need to wrap them in some sort of insulation-- something I could use advice on selecting as well as methods to keep the pipes warm in winter. They will be inside the room against a wall to avoid putting them inside an exterior wall.

I will move the toilet supply line over about 5' to the south and bring it up through the floor (again to avoid being inside an exterior wall). If it is possible, I would like to install a check valve on this so I can have a shattaf (handheld bidet sprayer) and I want to make sure there is no backflow.

The existing 3/4" supply lines for the washing machine would be moved inside the interior wall eastward a few feet to serve the shower/tub. The tub will be against the east and south exterior walls (with the longer side being on the east). I will have an access panel for the plumbing behind the tub inside the new laundry room.

The plumbing for the new lavatory is already somewhat in place (was roughed in for a utility sink) but will have to be moved slightly when the floor is redone so that the new vanity will sit forward away from the south wall about 3 or 4 inches. It is also 3/4" PVC and CPVC.

I already know what I want to do in terms of the DWV part, but I need to work on the specifics of the water supply. The lav and toilet will be against the south exterior wall, although there is a skirt that goes down to the ground, they are still vulnerable to cold in the winter (thus the existing lines are wrapped in foam).

My questions:

1. What is the best way to link 3/4" PVC & CPVC to PEX? (I do not have any of the crimping tools)

2. What is the best size PEX to use?

3. What is the best way to insulate the pipes under the house to keep them from freezing?

4. Where should I put the check valves (and can they be installed vertically?)

5. What kind of check valves should I use? (I've seen PVC & metal ones- solvent weld, threaded, & push-fit)

6. Any other suggestions?

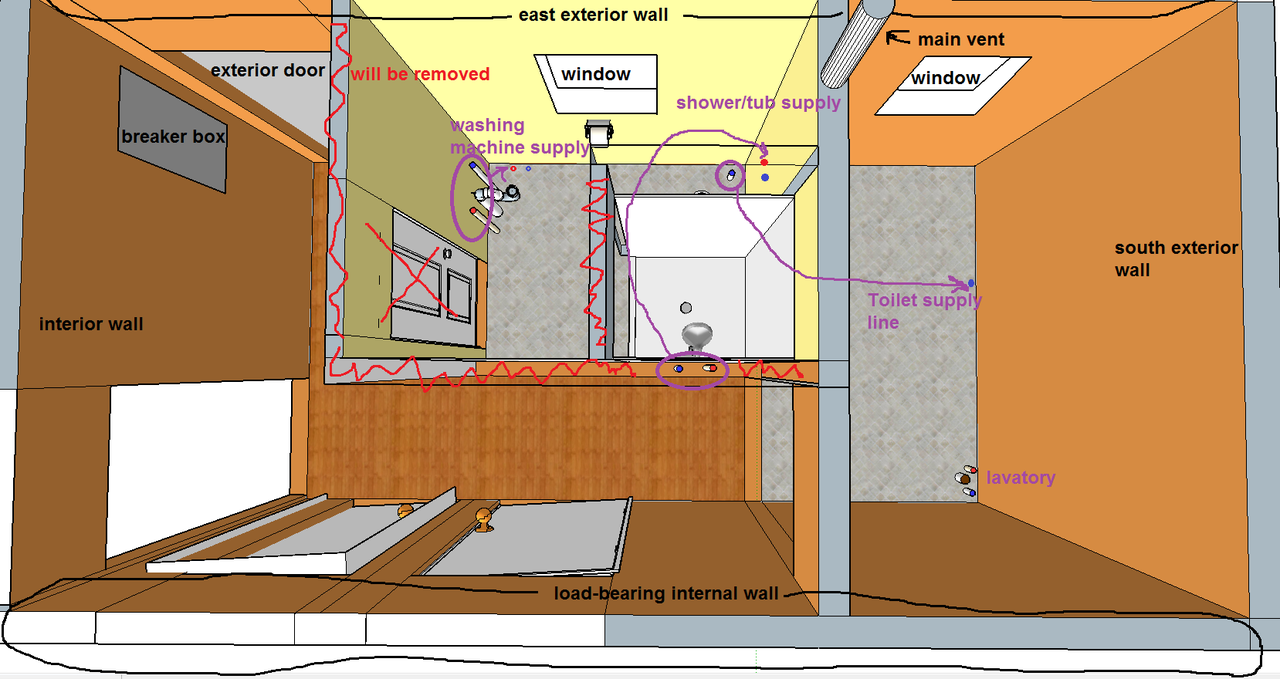

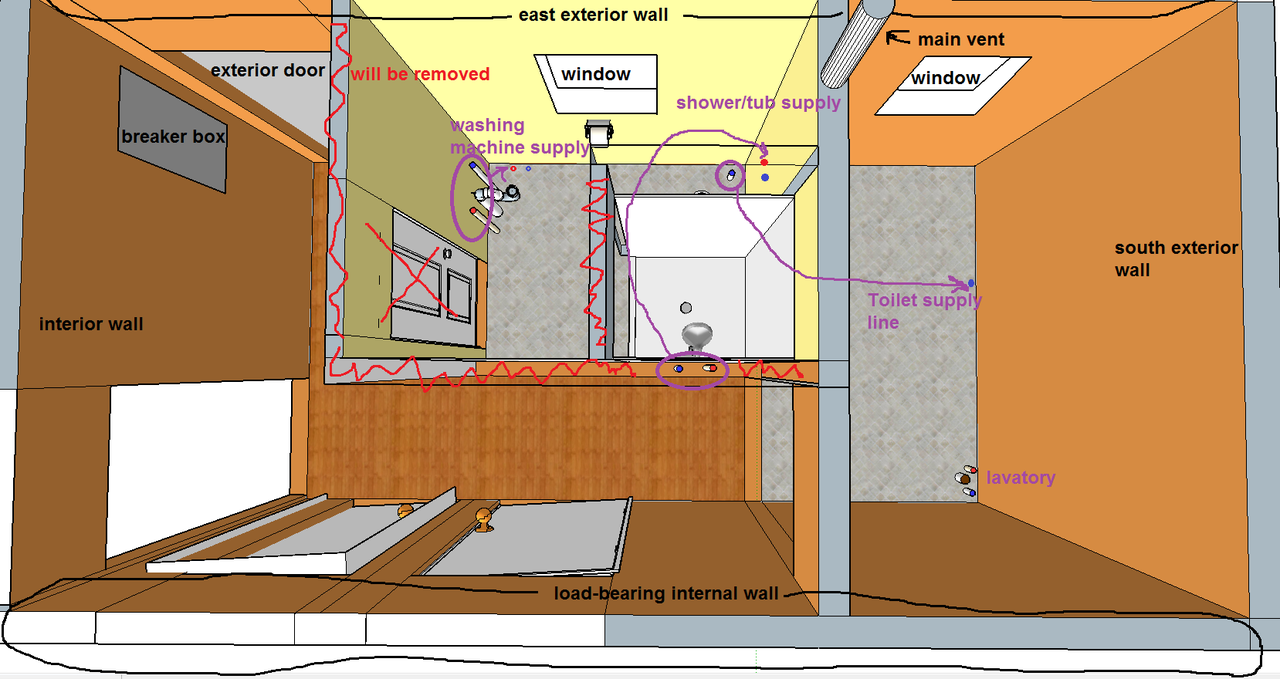

Here is a sketch of the current layout (with fixtures removed) and how I plan to move stuff

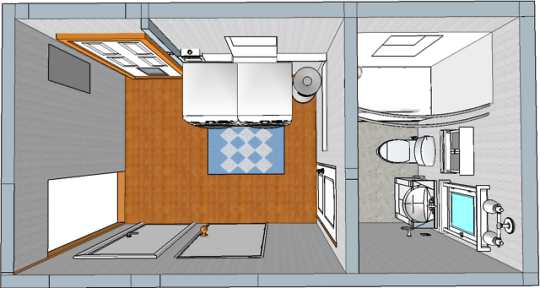

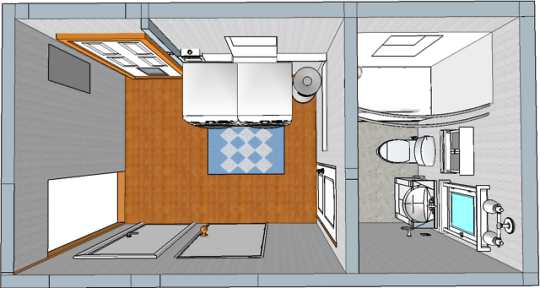

Here is a sketch of a general idea of the future layout

The main issue right now is that we want to switch the laundry room with the guest bathroom. To do this, we have to take down a couple small non-load bearing walls, move some of the plumbing over, and run new electrical (fortunately the main circuit box is in this area).

The temperature doesn't usually get below freezing here, but the last few years we've had colder weather than usual and it got down in the 20s and caused some pipes to rupture. The exterior walls seem to be 2x6s with a thin layer of plywood on the outside covered in house wrap. On the inside is 1/8" thick wood paneling. There is no insulation (something I intend to rectify when I remodel).

Building codes have changed so I know that PVC is no longer allowed above ground for water supply. I was recently told that in the past few years the code changed to require a check valve for the washing machine water supply lines. I'm trying to find the right type and size to use. The current supply lines are 3/4" PVC (for cold) and 3/4" CPVC (for hot).

Specific changes:

I need to move the supply lines for the current lavatory over less than a foot to work as the washing machine supply lines. This will bring them closer to the exterior wall (and exposed part under the house) so I will need to wrap them in some sort of insulation-- something I could use advice on selecting as well as methods to keep the pipes warm in winter. They will be inside the room against a wall to avoid putting them inside an exterior wall.

I will move the toilet supply line over about 5' to the south and bring it up through the floor (again to avoid being inside an exterior wall). If it is possible, I would like to install a check valve on this so I can have a shattaf (handheld bidet sprayer) and I want to make sure there is no backflow.

The existing 3/4" supply lines for the washing machine would be moved inside the interior wall eastward a few feet to serve the shower/tub. The tub will be against the east and south exterior walls (with the longer side being on the east). I will have an access panel for the plumbing behind the tub inside the new laundry room.

The plumbing for the new lavatory is already somewhat in place (was roughed in for a utility sink) but will have to be moved slightly when the floor is redone so that the new vanity will sit forward away from the south wall about 3 or 4 inches. It is also 3/4" PVC and CPVC.

I already know what I want to do in terms of the DWV part, but I need to work on the specifics of the water supply. The lav and toilet will be against the south exterior wall, although there is a skirt that goes down to the ground, they are still vulnerable to cold in the winter (thus the existing lines are wrapped in foam).

My questions:

1. What is the best way to link 3/4" PVC & CPVC to PEX? (I do not have any of the crimping tools)

2. What is the best size PEX to use?

3. What is the best way to insulate the pipes under the house to keep them from freezing?

4. Where should I put the check valves (and can they be installed vertically?)

5. What kind of check valves should I use? (I've seen PVC & metal ones- solvent weld, threaded, & push-fit)

6. Any other suggestions?

Here is a sketch of the current layout (with fixtures removed) and how I plan to move stuff

Here is a sketch of a general idea of the future layout