I understand that fiberglass insulation can be compressed into a thinner cavity than expected, to produce a higher R-value than that cavity would normally have (but not as high as the thicker product in the thicker cavity).

Does anyone know if the Bonded Logic Ultratouch R19 product can be compressed into a 3.5" cavity, and what it does to R-value and sound attenuation?

Thanks!

Almost all R19s are manufactured and tested with 6-6.25" of loft, and only perform at R18 when compressed to 5.5" in a 2x6 cavity. Compressing it further into a 3.5" cavity results in ~R13 performance.

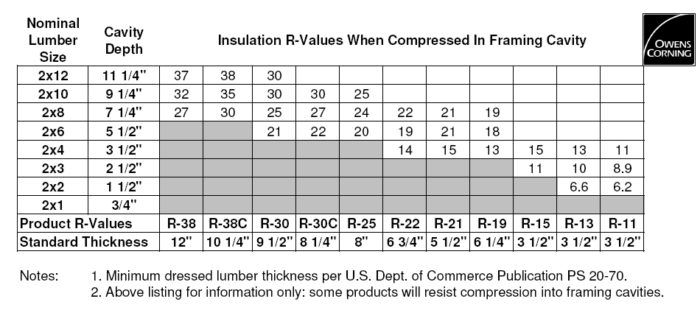

Here's the compression chart published by the pink fiber people:

There are similar charts from the yellow fiberglass folks.

Looking at the weights and calculating the density of the

Bonded Logic batts it might not follow exactly that track- the R19 batts are as low-density compared to their R13s as with fiberglass R19s, but they are lower density. There's nothing too magical about cotton fiber that would make it behave dramatically differently in an ASTM C518 test. But the higher thermal mass/lower thermal diffusivity compared to it's fiberglass competitors gives it a very modest real-world performance edge. I'm a bit surprised they don't make an R15 though.

As a general rule, compressing the batt further gives greater mechanical coupling, resulting in LESS sound attenuation through walls. Fiberglass & rock wool batts designed for sound attenuation are typically 3.0-3.25" thick, to avoid that spring-tension coupling when installed.