Jack Miller

New Member

Hello,

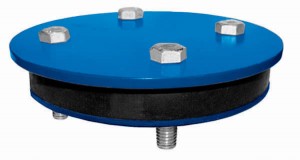

This may be a dumb question, but I've looked high and low online and am not able to find a simple cap (maybe it's called a plate) that was in place on one of my basement drains, but not the other. The drain is closed shut about a foot down or so, but open from there up to the basement floor. Now that the kids are using the basement more I don't want one of them twisting an ankle. I thought it'd be easy enough to find a replacement cap, but no luck at the local big box stores either.

Anyone know where I can find one of these??

Thanks!

This may be a dumb question, but I've looked high and low online and am not able to find a simple cap (maybe it's called a plate) that was in place on one of my basement drains, but not the other. The drain is closed shut about a foot down or so, but open from there up to the basement floor. Now that the kids are using the basement more I don't want one of them twisting an ankle. I thought it'd be easy enough to find a replacement cap, but no luck at the local big box stores either.

Anyone know where I can find one of these??

Thanks!