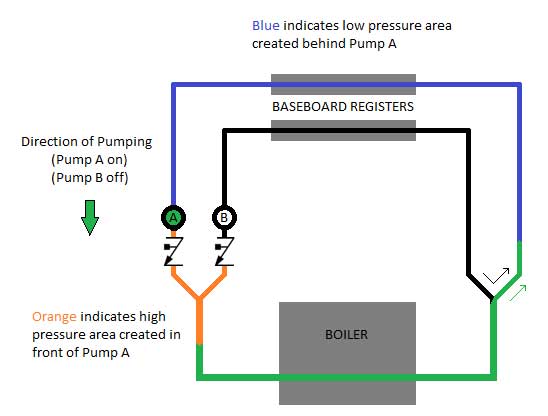

Dana, sorry I don't understand. With a check valve shielding pump B from backward flow, how can there be reverse pressure at pump B?

Perhaps we're getting hung up on semantics. The reverse pressure is blocked by the check valve, so there is no reverse flow. But that is the direction of the pressure differential.

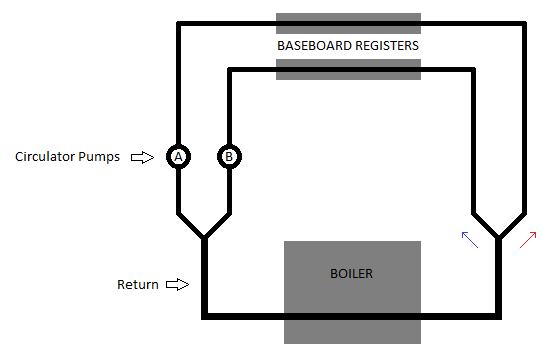

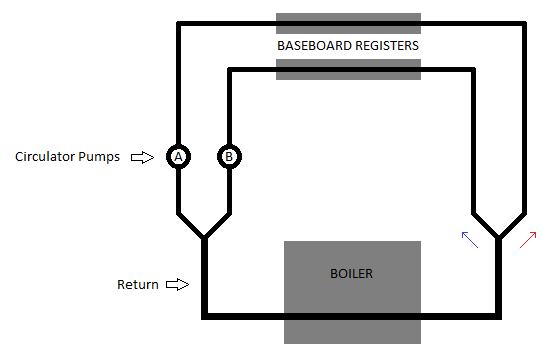

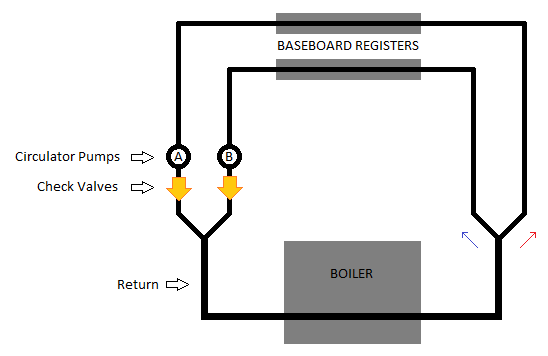

In addition, you mention that when unpowered the pump impeller spins freely, therefore an unpowered pump does not block water. Yet you also said that no zone valves are needed if you have a pump on each zone? I can't rectify these seemingly contradicting points in my head because if the unpowered pumps don't block the water, what is preventing hot water from entering a zone other than the one it is intended for? Please help me understand.

Water doesn't move until and unless something is creating a pressure difference. If reverse flows are being blocked by check valves on every zone, and there is no reverse pressure or flow at the pump, and there is no pressure in the positive direction being induced. The water in the off zone just sits there- it can't be sucked out at the wye at the right side of the diagram with the check valve at pump B, but if that valve were absent it would backflow on the pressures induced by pump A. The pump doesn't block the flow, the check valve does.

In some messy primary/secondary systems there can sometimes be a slight forward pressure on "off" zones induced by the primary pump, enough to spin the pump in the forward direction, but only rarely to the point of needing a zone valve.

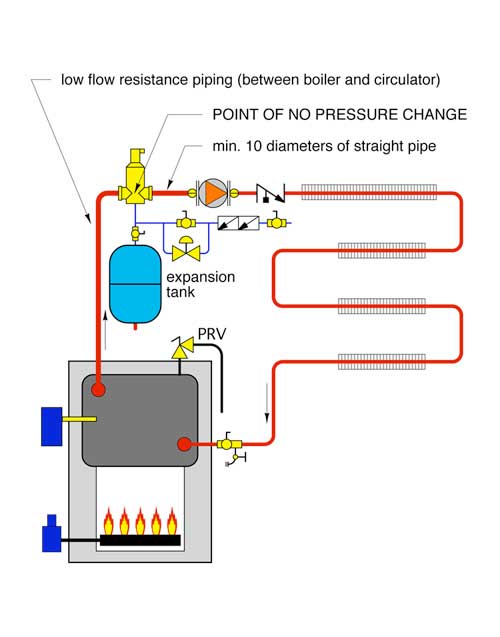

NOTE: I currently have a old Weil-Mclain cast iron boiler, and with 1 circulator pump on the return side of the boiler. The expansion tank is (perhaps incorrectly) located on the outflow side of the boiler.

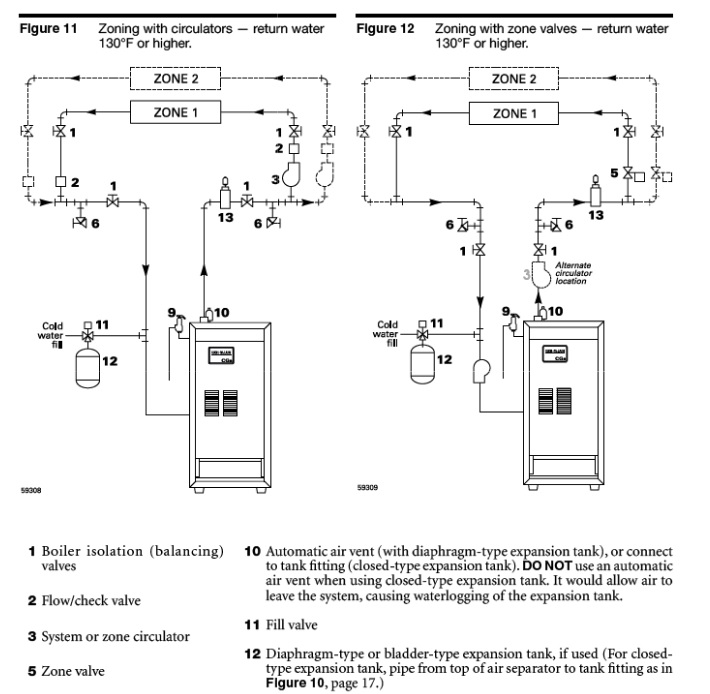

Yours and thousands of others are built that way and still working just fine. But from "best practices" perspective it's better to put the expansion tank at the input side of the pump, whether it's pumping toward or away from the boiler. But it gets complicated quickly when there are multiple pumps with different functions in different parts of the system (primary/secondary, multiple secondary loops etc.) which begs the question

Pumping Away From What?

With the very low head of a cast iron boiler like yours the expansion tank can reside in either side of the boiler, and as long as the pump is pumping away from the tank (even with the boiler in-between) the expansion tank is still protecting the pump if the pump is pumping away. So yours isn't ideal- don't sweat the small stuff. As long as it isn't chewing through pumps every few years and not sucking air into the system it's fine, no need to mess with it. But this is sort of the classic new-school recommendations for low head boilers like yours:

(The sideways Z symbol to the right of the pump is the standard for a check valve, not that it's really necessary in this one loop system.)

Another Note: I am not planning on making any changes to my current heating system. I am one of those guys who likes to dream of how I would set things up in my "dream house" in the future when I win the lottery and have tons of money to blow. I have had several zone valves fail over the years and a system that contains multiple circulator pumps but zero zone valves sounds appealing to me.

Newer "smart" ECM drive pumps programmed for constant-pressure feedback aren't as abusive to zone valves as typical split capacitor drive circulators, since the velocity of the water through any individual zone valve is never too high. With an old school pump and only one zone open the gpm through the valve can be pretty high, and the water-hammer when it closes can be pretty hard. With a smart pump it all gets dialed down, the pump speed/power rises and falls with then number of active zones.