dsungaila

New Member

Good afternoon folks!

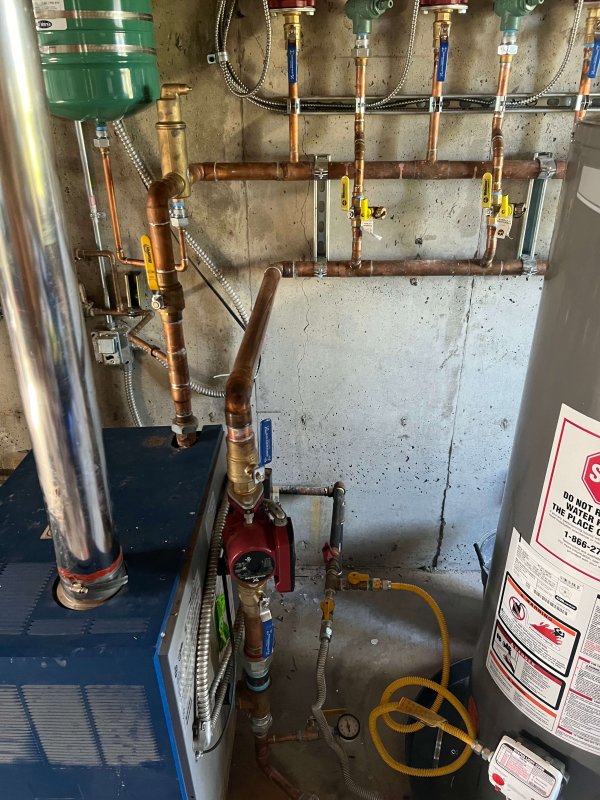

A little stumped - my zone valves that were 20 years old crapped out and I ended up replacing all of them with circulator pumps. I installed the pumps (see pics) to pull away froim the boiler into the zone. Each pump is on a thermostat, with Zone 1 being the biggest one (main living area). I have also installed a flow valve on each of the returns.

Issue is - whenever any of the pumps is on - all of the zones flow, even with the flow valves. I turned off the boiler circulator pump (took off the wires) and there was no flow present whatsoever. As if the boiler was not allowing any flow. Boiler is about 20 years old and I don't think it has load activated flow valve (if that is even a thing)?

Question is - what am I doing wrong? Or what can I try and change to make it work right for each zone?

A little stumped - my zone valves that were 20 years old crapped out and I ended up replacing all of them with circulator pumps. I installed the pumps (see pics) to pull away froim the boiler into the zone. Each pump is on a thermostat, with Zone 1 being the biggest one (main living area). I have also installed a flow valve on each of the returns.

Issue is - whenever any of the pumps is on - all of the zones flow, even with the flow valves. I turned off the boiler circulator pump (took off the wires) and there was no flow present whatsoever. As if the boiler was not allowing any flow. Boiler is about 20 years old and I don't think it has load activated flow valve (if that is even a thing)?

Question is - what am I doing wrong? Or what can I try and change to make it work right for each zone?