My brine line tubing is 3/8 OD.

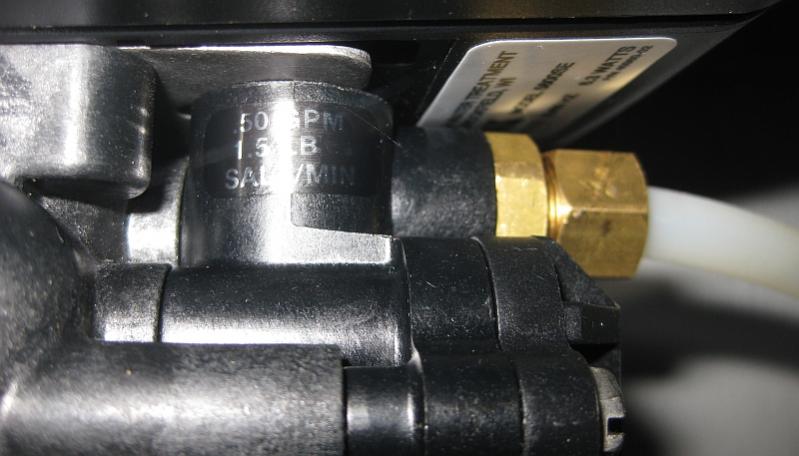

Is the brass nut on the right going to be 3/8 compression, and the left side of the adapter going to be 3/8 MIP screwed into the plastic FIP?

I am thinking of doing a batch treatment of my media. I was thinking of unscrewing the nut, and putting on another line just for the purpose of drawing a cleaning solution in during a BD cycle.

For my plan, I am thinking to put about 4 gallons of treatment solution into a 5 gallon bucket. With an alternate brine hose in the bucket, put the unit into brine draw. Pull the power to keep the valve in BD. Once the bucket is almost sucked dry, put the system into bypass. Tank should be full of treatment solution. Leave to sit for a time, some number of hours I am thinking.

So how is 4 gallons of treatment solution enough?

1. I am estimating the media will be about 0.66 of the column height. About 0.50 of that space will be consumed by media rather than water. (0.5 is probably a little low for resin and high for carbon). That says I need about 10.72 gallons of solution in the tank.

2. When solution is drawn, it is diluted to about 3x the volume sucked in. So if I draw 4 gallons, I get about 12 gallons after the injector.

Is the brass nut on the right going to be 3/8 compression, and the left side of the adapter going to be 3/8 MIP screwed into the plastic FIP?

I am thinking of doing a batch treatment of my media. I was thinking of unscrewing the nut, and putting on another line just for the purpose of drawing a cleaning solution in during a BD cycle.

For my plan, I am thinking to put about 4 gallons of treatment solution into a 5 gallon bucket. With an alternate brine hose in the bucket, put the unit into brine draw. Pull the power to keep the valve in BD. Once the bucket is almost sucked dry, put the system into bypass. Tank should be full of treatment solution. Leave to sit for a time, some number of hours I am thinking.

So how is 4 gallons of treatment solution enough?

1. I am estimating the media will be about 0.66 of the column height. About 0.50 of that space will be consumed by media rather than water. (0.5 is probably a little low for resin and high for carbon). That says I need about 10.72 gallons of solution in the tank.

2. When solution is drawn, it is diluted to about 3x the volume sucked in. So if I draw 4 gallons, I get about 12 gallons after the injector.