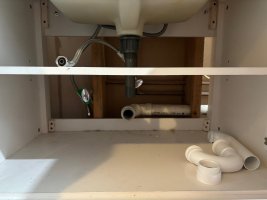

Hello - I'm having a hard time determining how to do the drain on my bathroom vanity. I've attached two pictures. One shows the wall plumbing that goes to the stack. The other shows under the vanity. There is a shelf in the vanity that I would prefer not to cut if I can avoid it. If I can't, let me know.

The pvc from the wall, when inside the vanity, is 2.5 inches above the shelf in the vanity. The drain from the sink drops down to about 6" above the shelf. The horizontal distance between the PVC and the drain is also approximately 6".

The 2.5" that the PVC is above the shelf doesn't provide me with enough room to have a trap that's below that level. Am I wrong?

Any ideas other than cutting? Thanks so much!

The pvc from the wall, when inside the vanity, is 2.5 inches above the shelf in the vanity. The drain from the sink drops down to about 6" above the shelf. The horizontal distance between the PVC and the drain is also approximately 6".

The 2.5" that the PVC is above the shelf doesn't provide me with enough room to have a trap that's below that level. Am I wrong?

Any ideas other than cutting? Thanks so much!