Hi, my daughter is remodeling her guest bath on a home she recently purchased. Small, semi-functional bathroom we are trying to update and make more functional. Existing layout had a 20" vanity, toilet and big open space to tub (pic of old space). Going to be moving toilet about 10.5" toward the tub/shower. She bought a 30" vanity and roughly centering the toilet gives me about 17" from the new flange center to the tub and vanity. She also bought a fairly skinny toilet to help with space. Dry fit photo of semi-demo'd bath provided. UPC in this area but not sure which version. Would like to follow code and apologize for the length of this in advance.

Question/Advice #1 (multiple): After demo'ing the dry wall and vanity, there were two drain/vent lines coming off the same 2" vent line which runs to the left (see picture). The first drop going left to right is the vent for the toilet drain, the right 1 1/2" line is the vent/drain for the vanity. My plan is just to convert all the vanity DWV to 2" and thus it will wet vent into the toilet waste pipe. I will then just cap the 1 1/2" after making a cleaner cut (just had my multitool that day). I guess in theory if rain water got into the vent from above and followed slope, I should be fine with the capped end because it would hit the 2" first. The 2" DWV pipe lines up roughly center with the new vanity so that works out well. However it complicates the supply line placement since there isn't much space for the hot supply to left of 2" and stud on left. My plan is to replace all the copper supply I can get to easily with Pex A. She doesn't want any PEX exposed on the stub outs and for the life of me I can't find anything that allows me a stable Pex stub out with finish trim. So was going to go with copper stub outs. Hot immediately left of stud (which puts it about 6" to left of 2" ABS center and the cold similar spacing to the right. I'm not aware of any code that specifies location of supply lines and not trying to make my life any harder here. Am I doing okay so far and any advice on supply lines both in terms of location and finishing. As you can see from the pic, it's a closed vanity (not a pedestal sink) so no one is going to see the location of the supply lines.

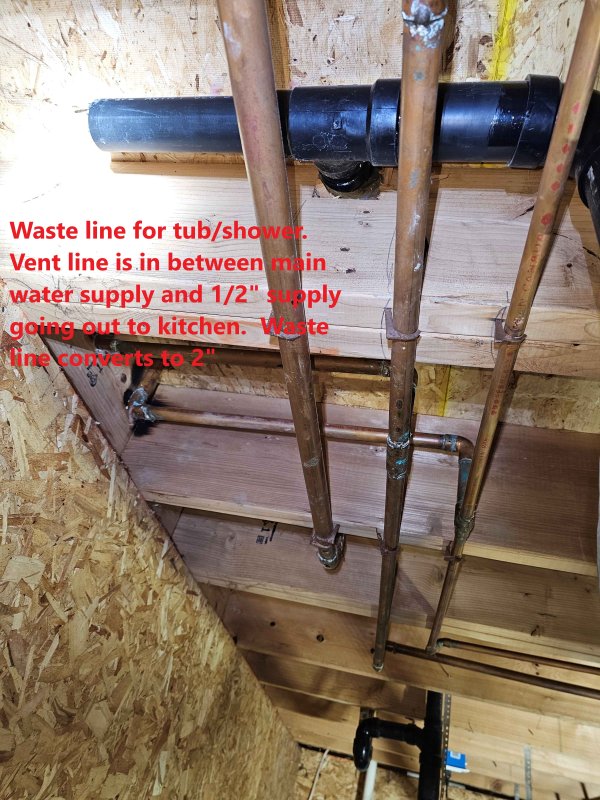

Question/Advice #2: The new tub has been dry fit. Studs need some tuning in preparation for tile backer, need to get some mortar down, add the drain kit for the tub and get it installed. I have already demo'd the existing 1 1/2" ABS drain/waste line that was going to the old tub/shower back into the crawl. As you can see from the pics, there in an access location underneath the tub accessible from the crawl. Crawl is probably 5' high in this area. For purposes of finishing out the waste from the tub kit to the P trap and P trap to rest of run, I was planning on using slip joint nuts so I could take it out if there are clogs etc. My understanding is that if the location/DWV is accessible, this would be acceptable and not every connection would need to be cemented. Good so far...?

Question/Advice #3: As mentioned, will be replacing copper with PEX A where possible including supply lines to tub/shower mixer. Included a pic of the open wall where the mixer would go. The copper supply emerges from some studs to the left and then there is a 90 just a little bit further to the right where it's fed from with a T fitting with the other side going to the vanity and toilet supply. All of the copper pipe is plumbed fairly deep in the wall (with nail plates on the other side). I tore out a stud that was in the way and need to add a new one in slightly to the left so I'll have a good stud bay for the mixing valve and supply runs. She hasn't picked out her mixing valve yet but will be either Moen or Delta and she hasn't picked out tile yet. But my guess is normal thickness of 12x24 tile which means 1/4" of thinset using a 1/2" trowel and using ½” Go-Board for the tile backer. Looking for some ideas on how to route my PEX once I transition from copper (which I will probably do as close to the stud to the right as possible on both hot and cold) factoring in tub faucet supply etc. Right now if I brought the hot supply out horizontally think I'm going to have issues with the tub faucet supply dropping from the mixer but it may tuck in behind.

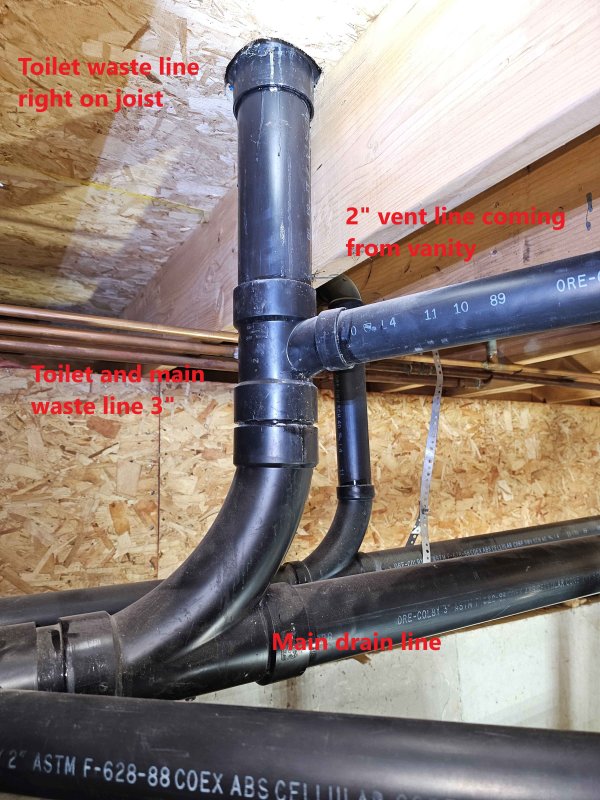

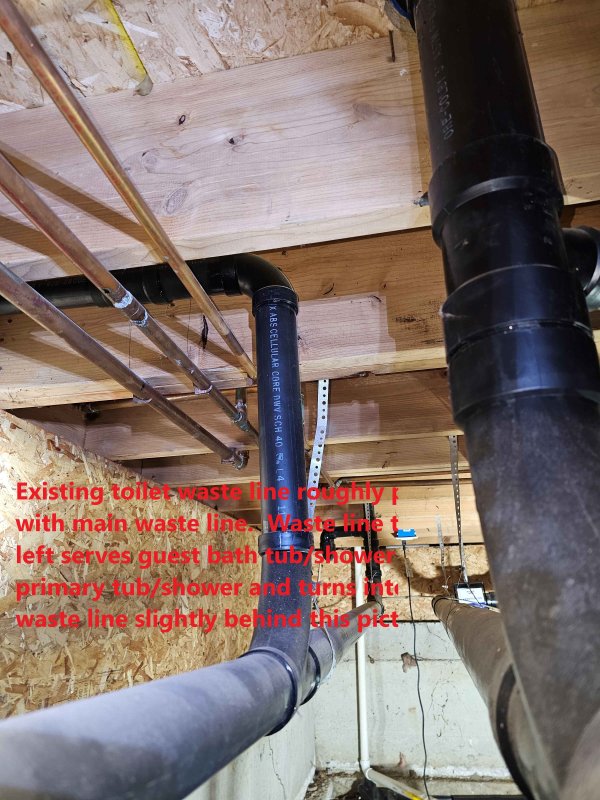

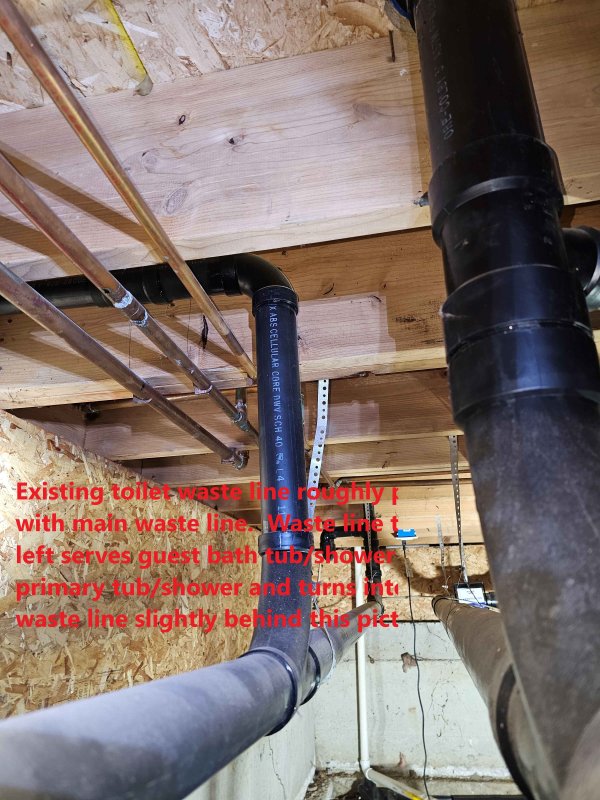

Question/Advice #4: Saved the one I’m most perplexed on for last. As mentioned, moving toilet ~10.5” to the left. Joists underneath run the length of the bathroom and 2x10 and 16” OC. I also have the other issue that the current toilet is a 14” rough-in and she would like a 12” rough to stick with a smaller toilet she bought but that would have the hole for the waste line landing on top of the joist. I have read about the Toto Unifit but I’ve got to drill a new hole anyway and the Toto is quite a bit more than she spend for what’s in the picture. So I’m a bit perplexed on best options for handling a 12” rough in (not against creating a plumber’s box particularly because nothing runs through the joists but…) and also very perplexed on how to cut out the existing toilet drain connection out of the main line and put humpty dumpty back together to locate to the new toilet flange site and what fittings I will need.

I realize there is no insulation in the crawl and no insulation on the pipes. Funny/sad story that is going to cost my daughter some $$ but lesson well learned. Any advice appreciated and again, apologies for the long post.

Question/Advice #1 (multiple): After demo'ing the dry wall and vanity, there were two drain/vent lines coming off the same 2" vent line which runs to the left (see picture). The first drop going left to right is the vent for the toilet drain, the right 1 1/2" line is the vent/drain for the vanity. My plan is just to convert all the vanity DWV to 2" and thus it will wet vent into the toilet waste pipe. I will then just cap the 1 1/2" after making a cleaner cut (just had my multitool that day). I guess in theory if rain water got into the vent from above and followed slope, I should be fine with the capped end because it would hit the 2" first. The 2" DWV pipe lines up roughly center with the new vanity so that works out well. However it complicates the supply line placement since there isn't much space for the hot supply to left of 2" and stud on left. My plan is to replace all the copper supply I can get to easily with Pex A. She doesn't want any PEX exposed on the stub outs and for the life of me I can't find anything that allows me a stable Pex stub out with finish trim. So was going to go with copper stub outs. Hot immediately left of stud (which puts it about 6" to left of 2" ABS center and the cold similar spacing to the right. I'm not aware of any code that specifies location of supply lines and not trying to make my life any harder here. Am I doing okay so far and any advice on supply lines both in terms of location and finishing. As you can see from the pic, it's a closed vanity (not a pedestal sink) so no one is going to see the location of the supply lines.

Question/Advice #2: The new tub has been dry fit. Studs need some tuning in preparation for tile backer, need to get some mortar down, add the drain kit for the tub and get it installed. I have already demo'd the existing 1 1/2" ABS drain/waste line that was going to the old tub/shower back into the crawl. As you can see from the pics, there in an access location underneath the tub accessible from the crawl. Crawl is probably 5' high in this area. For purposes of finishing out the waste from the tub kit to the P trap and P trap to rest of run, I was planning on using slip joint nuts so I could take it out if there are clogs etc. My understanding is that if the location/DWV is accessible, this would be acceptable and not every connection would need to be cemented. Good so far...?

Question/Advice #3: As mentioned, will be replacing copper with PEX A where possible including supply lines to tub/shower mixer. Included a pic of the open wall where the mixer would go. The copper supply emerges from some studs to the left and then there is a 90 just a little bit further to the right where it's fed from with a T fitting with the other side going to the vanity and toilet supply. All of the copper pipe is plumbed fairly deep in the wall (with nail plates on the other side). I tore out a stud that was in the way and need to add a new one in slightly to the left so I'll have a good stud bay for the mixing valve and supply runs. She hasn't picked out her mixing valve yet but will be either Moen or Delta and she hasn't picked out tile yet. But my guess is normal thickness of 12x24 tile which means 1/4" of thinset using a 1/2" trowel and using ½” Go-Board for the tile backer. Looking for some ideas on how to route my PEX once I transition from copper (which I will probably do as close to the stud to the right as possible on both hot and cold) factoring in tub faucet supply etc. Right now if I brought the hot supply out horizontally think I'm going to have issues with the tub faucet supply dropping from the mixer but it may tuck in behind.

Question/Advice #4: Saved the one I’m most perplexed on for last. As mentioned, moving toilet ~10.5” to the left. Joists underneath run the length of the bathroom and 2x10 and 16” OC. I also have the other issue that the current toilet is a 14” rough-in and she would like a 12” rough to stick with a smaller toilet she bought but that would have the hole for the waste line landing on top of the joist. I have read about the Toto Unifit but I’ve got to drill a new hole anyway and the Toto is quite a bit more than she spend for what’s in the picture. So I’m a bit perplexed on best options for handling a 12” rough in (not against creating a plumber’s box particularly because nothing runs through the joists but…) and also very perplexed on how to cut out the existing toilet drain connection out of the main line and put humpty dumpty back together to locate to the new toilet flange site and what fittings I will need.

I realize there is no insulation in the crawl and no insulation on the pipes. Funny/sad story that is going to cost my daughter some $$ but lesson well learned. Any advice appreciated and again, apologies for the long post.