M'Arm Strong

New Member

Hey everyone, my name is Michael. I’ve been lurking around here for several years gathering up tons of information from you good folks. A belated thanks is owed to everyone that has indirectly helped me through many home renovation projects.

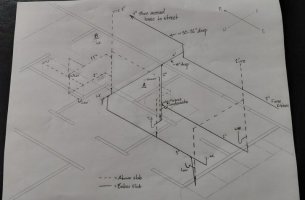

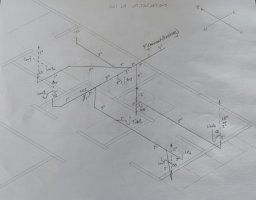

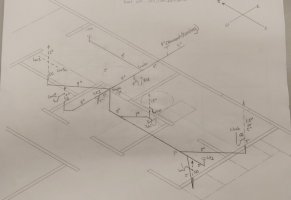

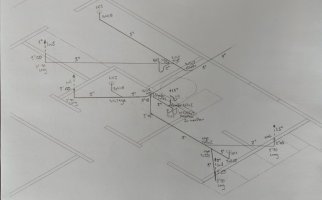

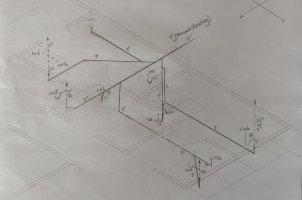

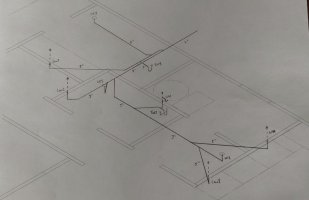

This year I bought my childhood home and completely gutted it. The new floorplan necessitates all new DWV plumbing. It’s a slab on grade single-story ranch. It was tied into city sewer in 2012 and everything from the foundation to the road is new. It’s located in Ohio and governed by Ohio Plumbing Code, which I understand to be IPC-based.

My last whole-house replumb was just one bath and a kitchen, so I could wrap my head around that one pretty easy. The new house is another story. The kitchen is good as-is, but I’m plumbing in 2.5 bathrooms and laundry. I’m trying to minimize cuts in the concrete if possible and hoping to keep the existing roof penetration (hence why some of the lav branches are in the wall). I also have very little space for connecting multiple vent branches in the attic.

I’m comfortable spec’ing pipe sizes and fittings. My main issue is getting the shower (labeled A) and the WC (labeled B) tied in without a ton of bends and without going so deep (because of the vents) that I can’t meet fall requirements when tying to the main. I’ve tried may iterations but haven’t been happy with any of them. The WC is about 7 feet from the double vanity, so I don’t think a wet vent is in the cards.

I know you master plumbers out there will find this one easy! Criticism is welcome on the rest of the layout as well. I’m all about overkill, but if there’s an elegant solution with fewer pipes, I’d love to hear it!

Thanks in advance, and the beers are on me!

This year I bought my childhood home and completely gutted it. The new floorplan necessitates all new DWV plumbing. It’s a slab on grade single-story ranch. It was tied into city sewer in 2012 and everything from the foundation to the road is new. It’s located in Ohio and governed by Ohio Plumbing Code, which I understand to be IPC-based.

My last whole-house replumb was just one bath and a kitchen, so I could wrap my head around that one pretty easy. The new house is another story. The kitchen is good as-is, but I’m plumbing in 2.5 bathrooms and laundry. I’m trying to minimize cuts in the concrete if possible and hoping to keep the existing roof penetration (hence why some of the lav branches are in the wall). I also have very little space for connecting multiple vent branches in the attic.

I’m comfortable spec’ing pipe sizes and fittings. My main issue is getting the shower (labeled A) and the WC (labeled B) tied in without a ton of bends and without going so deep (because of the vents) that I can’t meet fall requirements when tying to the main. I’ve tried may iterations but haven’t been happy with any of them. The WC is about 7 feet from the double vanity, so I don’t think a wet vent is in the cards.

I know you master plumbers out there will find this one easy! Criticism is welcome on the rest of the layout as well. I’m all about overkill, but if there’s an elegant solution with fewer pipes, I’d love to hear it!

Thanks in advance, and the beers are on me!