I realize that my other thread about the fiberglass tub got confusing because it started out about a different bathroom and I moved on to my ensuite. I have two ensuites back to back. I'm not sure when the original house was built but the ensuites and bedrooms attached to them seem to have been added in the late 1940s (Feb 1947 according to writing on a beam under the house). The bathrooms were renovated sometime in the 70s. Both got printed wood paneling with vertical stripes.

The vanity is made of plywood and is built in. It originally had carpet but I tore out as much of it as I could (some is still under the vanity). There was a moisture barrier between the subfloor and underlayment plywood. I ripped out the carpet and we had cheap vinyl sheet installed. When the septic tank backed up it flooded the bathroom and ruined the underlayment (the other bathroom didn't have that so it ruined the subfloor).

I pulled the toilet to find carpet and carpet pad underneath. The wood was like mud. I removed the entire damaged section and replaced it with 1/4" lauan that was then coated in wood sealant. It wasn't the same level as the old plywood so I tried to level it with leveling mix (employee at the store said it was self leveling but it wasn't). It was also a bad batch full of clumps. It came out like the surface of the moon with sharp points sticking up and was awful. My friend was helping me and poured the stuff even when I noticed there were lumps after I said it looked bad. I tried hammers, chisels, sandpaper, etc to try to smooth it out but the additive made it too tough.

Round 2 of the leveling was without additive and after we used diamond tipped grinding tool to grind down the high spots and smooth it out as best as we could. The layer to fill in the spots was much weaker than the stuff with additive and was a bit powdery (but it could be sanded and chiseled). I decided to try round 3 on my own. I screwed up and got the ratios mixed up and had to sift lumps out of the powder. Despite my screwup, I got it to the right consistency and got it as smooth as I could (using additive for strength). It's not perfect but its better than nothing and I decided to leave it alone.

This project has gone on way too long (over a decade) and while I've got the floor fixed and toilet installed, I am currently working on the tub walls. I'm going to post some pics of the progress. I wish I had pics of the original ugly carpet. It was beige at one point but the tenants that lived here while we were overseas never cleaned it and it was really gross.

This is what it looked like after the toilet was pulled out (after the flooding).

Botched floor leveling job attempt 1.

2nd coat after grinding

Final coat

I installed the vinyl sheet by myself (which was a royal pain). It's looselay so I did perimeter tape. I'll be adding baseboards later. The part of the wall I painted white will get wainscoting.

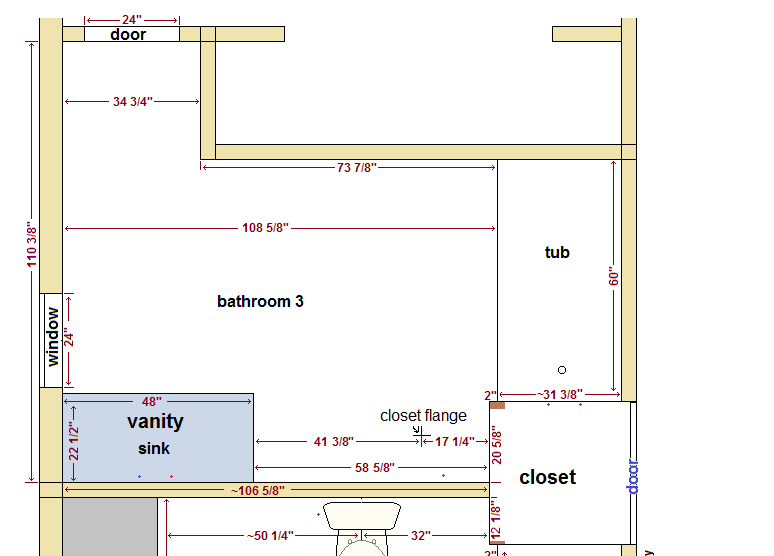

Sketch showing layout of this room and adjacent bathroom. I have wall thickness wrong because I didn't realize its way thicker than expected.

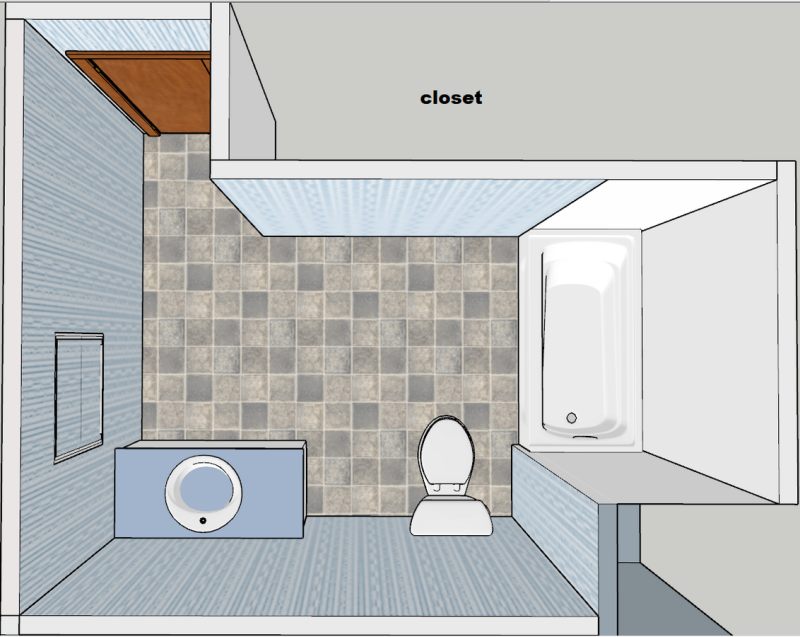

Rough sketchup drawing of the room

One problem I'm facing is that the idiots who did the renovation in the 70s cut all the way through a joist so I will have to remedy that with a box and sistering it up a bit. I will go with a direct drain instead of the regular kind. It appears to be an above the floor drain so its going to be tricky to access it and get the holes drilled since I suspect there is mortar under the tub (it is not even nailed in place but it won't budge).

The vanity is made of plywood and is built in. It originally had carpet but I tore out as much of it as I could (some is still under the vanity). There was a moisture barrier between the subfloor and underlayment plywood. I ripped out the carpet and we had cheap vinyl sheet installed. When the septic tank backed up it flooded the bathroom and ruined the underlayment (the other bathroom didn't have that so it ruined the subfloor).

I pulled the toilet to find carpet and carpet pad underneath. The wood was like mud. I removed the entire damaged section and replaced it with 1/4" lauan that was then coated in wood sealant. It wasn't the same level as the old plywood so I tried to level it with leveling mix (employee at the store said it was self leveling but it wasn't). It was also a bad batch full of clumps. It came out like the surface of the moon with sharp points sticking up and was awful. My friend was helping me and poured the stuff even when I noticed there were lumps after I said it looked bad. I tried hammers, chisels, sandpaper, etc to try to smooth it out but the additive made it too tough.

Round 2 of the leveling was without additive and after we used diamond tipped grinding tool to grind down the high spots and smooth it out as best as we could. The layer to fill in the spots was much weaker than the stuff with additive and was a bit powdery (but it could be sanded and chiseled). I decided to try round 3 on my own. I screwed up and got the ratios mixed up and had to sift lumps out of the powder. Despite my screwup, I got it to the right consistency and got it as smooth as I could (using additive for strength). It's not perfect but its better than nothing and I decided to leave it alone.

This project has gone on way too long (over a decade) and while I've got the floor fixed and toilet installed, I am currently working on the tub walls. I'm going to post some pics of the progress. I wish I had pics of the original ugly carpet. It was beige at one point but the tenants that lived here while we were overseas never cleaned it and it was really gross.

This is what it looked like after the toilet was pulled out (after the flooding).

Botched floor leveling job attempt 1.

2nd coat after grinding

Final coat

I installed the vinyl sheet by myself (which was a royal pain). It's looselay so I did perimeter tape. I'll be adding baseboards later. The part of the wall I painted white will get wainscoting.

Sketch showing layout of this room and adjacent bathroom. I have wall thickness wrong because I didn't realize its way thicker than expected.

Rough sketchup drawing of the room

One problem I'm facing is that the idiots who did the renovation in the 70s cut all the way through a joist so I will have to remedy that with a box and sistering it up a bit. I will go with a direct drain instead of the regular kind. It appears to be an above the floor drain so its going to be tricky to access it and get the holes drilled since I suspect there is mortar under the tub (it is not even nailed in place but it won't budge).