Y2JDMBFAN

New Member

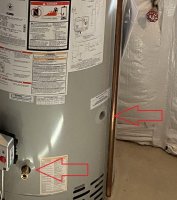

To keep a long story short, my water heater needed to be replaced with a new one for reasons unrelated to this problem. After it was installed we found that we weren't getting hot water in any of the bathrooms. Come to find out there were 4 passive re-circulation lines with home runs from each bathroom back to the hot water heater and no pump and they header off into the cold water inlet of the water heater. Well, when we closed all the ball-valves on each re-circ line, we got hot water. I was a totally newb in regards to re-circ lines. I did my research and we think that the check valves after the ball valve on each line are probably bad. The plumber suggested putting in a pump, and at the time I didn't know what he was talking about, but I did research and now understand it.

So my plan to fix the re-circ lines is the following.

1. Install (4) of the Callefi Balancing valves, 1 on each re-circ line after the ball valve with flow towards the new re-circ pump.

https://www.caleffi.com/usa/en-us/catalogue/thermosettertm-thermal-balancing-valve-116140a

2. Install a new re-circulating pump piped from the (4) re-circ lines into the drain on the new Bradford White 75Gallon POwer Vent. I was looking at this pump.

https://www.supplyhouse.com/Goulds-...Pump-w-Adjustable-Thermostat-and-Plug-1-2-FPT

I will have the plumber who installed the water heater do the work. Does t his sound like the correct solution to you guys? I figure I can set all of the balancing valves to the same temp and then set the re-circ pump to slightly higher.

Am I missing anything? Correct me if I am off-base here.

So my plan to fix the re-circ lines is the following.

1. Install (4) of the Callefi Balancing valves, 1 on each re-circ line after the ball valve with flow towards the new re-circ pump.

https://www.caleffi.com/usa/en-us/catalogue/thermosettertm-thermal-balancing-valve-116140a

2. Install a new re-circulating pump piped from the (4) re-circ lines into the drain on the new Bradford White 75Gallon POwer Vent. I was looking at this pump.

https://www.supplyhouse.com/Goulds-...Pump-w-Adjustable-Thermostat-and-Plug-1-2-FPT

I will have the plumber who installed the water heater do the work. Does t his sound like the correct solution to you guys? I figure I can set all of the balancing valves to the same temp and then set the re-circ pump to slightly higher.

Am I missing anything? Correct me if I am off-base here.