pcarpe01

New Member

I noticed on a new cable run to my dryer that the cable gets slightly warm, along with the breaker after running for 30 minutes. The only reason I noticed it was that I was running additional cables to the panel, which were cold to the touch, but the cable for the dryer is slightly warmer. Slightly meaning, that if I touched the dryer cable only, I wouldn't have thought twice about it or realized that it was warm - if that makes sense. I noticed the breaker is also slightly warm. The cable is consistently warm throughout the run - no hot spots.

The cable is new 10/3 NM with a 30 A breaker. It's a home run of about 20', there are no sharp bends/twists in the cable and the staples are not squashing the cable. I rechecked the connections and re-seated the breaker with the same results. the dryer is a Whirlpool, about 3 years old. The lint trap/line is clean.

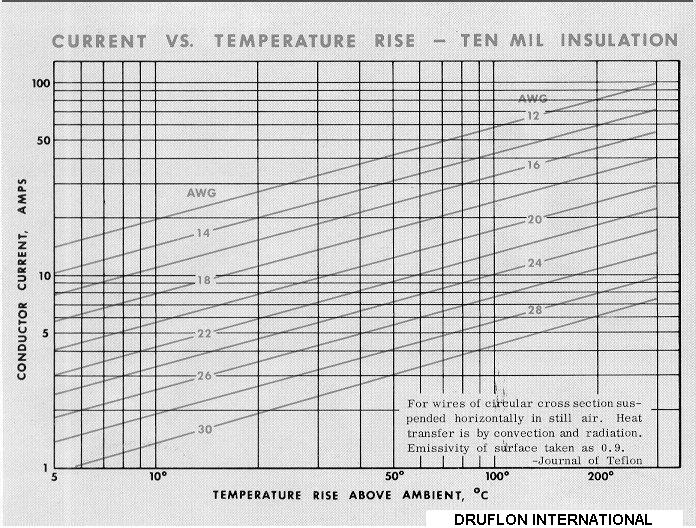

I was wondering if this is normal for the cable and breaker to become slightly warm due to continuous high current load? I just never noticed it before.

The cable is new 10/3 NM with a 30 A breaker. It's a home run of about 20', there are no sharp bends/twists in the cable and the staples are not squashing the cable. I rechecked the connections and re-seated the breaker with the same results. the dryer is a Whirlpool, about 3 years old. The lint trap/line is clean.

I was wondering if this is normal for the cable and breaker to become slightly warm due to continuous high current load? I just never noticed it before.