PS Carry:. I don't consider a good sized tank to be a negative. Especially during hurricane season.

"Hurricane" one of my trigger words, got a powerful itch & gotta scratch it. This may get lengthy you should probably just print it down & use it as humoress bathroom reading material.

I AGGREE, a pressure tank is handy during times of power outages. SHE can get 7 or 8 flushes with her water saver commode in one of her 2 upstairs bathrooms, thats right she has 2 full sized bathrooms, (me the dog & the cats share a small downstairs). During power outages I normally relieve outside - usually on her rose bushes. During a recent lizard hunting expedition with 8 year old grandson he felt the urge so grandpa taught him how to relieve on the bushes, afterwards in his excitement of what he perceived as something grandiose he ran into the house & excitedly told mom & grandma what he had been taught. Following which there was a shit storm of biblical proportions that lasted quite some days.

I have a flex right 80 gallon tank I installed a few years ago for a contact tank for chlorinator de-chlorinator system, the steel tank that used to be here had developed a pinhole (rust) seepage. I need only a 2-3 ppm mix in the tank to take care of low sulfur & iron, works very well. Carbon in back wash tank usually last between 4-5 years.

After a hurricane we can use the water in the contact tank by either first a carbon gravity filter, (the one I have was originally designed for military use in the field), other option is use aquarium pump with airstone & generally within 24 hours chlorine level below 1ppm. Also the water in 50 gl water heater And the bath tubs. No worries on water storage.

I have a couple inverter generators & portable air conditioners which have 2 gl buckets that store condensate, when full we pour them into the commode tank. Then there is always setting out buckets & catching rain water. With the inverter generators there are parallel cables to hook them together so I have a total of 52 amps but not 220v only 115 volt. Generators are trii-fuel NG, LP, unleaded, 285 gallon underground LP tank, 3 portable unleaded storage tanks total 65 gl.

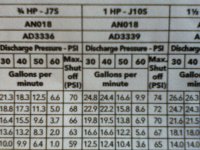

Texas wellman; the pump motor is 1 hp 9 amp to answer your previous question that I forgot to answer & is wired for 220v from main breaker box. Generator plugs into 30amp plug on outside of house to power up main breaker box (& yes have lock out transfer switch) just have to insure to turn off all 220v breakers.I could run the pump on 115v but don't trust myself reading the wiring diagrahm on the back plate thru the use of a mirror & moving the wires around corectly. Notice how close back of motor is to wall previouse pictures. Don't expect me to try any more

pictures for awhile.

Was on 2 large below ground septic systems nothing wrong with them but city installed suction sewer system thru street & was advised that impact fees were 1/2 to tie on now & if I didn't can't sell house until I do tie on plus city would have to inspect septic systems every 3 years & cost of pumping tanks/ inspection fees etc: I felt forced to tie on. Problem was tap / pod was not deep enough to allow me to run gravity sewer to tap so I installed a 2000 gl lift station with an oversized pump. I manualy turn pump on to get it completely empty just as the hurricane hits otherwise I have floats set so tank never gets above 1/3 full. Should pod fill up because city unable to keep suction pumps /system working after hurricane my lift station will force feed the pod & will no doubt go up the neighbors sewer. Don't like them neibours anyways (renters).

I'm fairly decided on replacing my blown bladder tank with a csv but now am hearing from others that they leak & the ones you can get that don't leak don't work as well. I keep getting pushed into straddle the fence mode. Will be draining down & cutting everything loose to get tank out Tuesday, hopefully I hear more positive feedback on cvs.

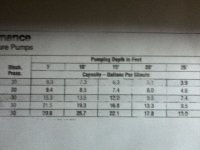

Another thought might be to upgrade to a Goulds J10s set at 40/60 an 86 gallon X trol and if that isn't sufficient then add a csv set for 50psi,

not sure would have to experiment. And from what I can see the goulds is easy to switch from 220v to 115v if I need to.

My primary objective is to increase pressure & flow for her upstairs bathrooms from 40/43 2 1/2 gl per minute to around 53 psi without the use of a booster pump or going to a 1 1/2 hp pump. With a 1 1/2 hp pump I would probably over limit generators on 115v if I ever had to power it that way. All the years of untold sacrifices SHE endured overseas in third world countries & islands during my military career I now would like to make her as comfotable as possible in what is termed our golden years and the water is just one of many items on my list.

Thanx for advice and allowing me to occasionally bend your ears.

V / R Dwayne