DoctorLem

New Member

Greetings and thank you for taking a look at my post.

Apologies in advance for my asking of any relatively elementary questions.

I have be working on a complete rebuild of my house for the past 5 years, which has left me in a completely open, new construction status/blank slate for HVAC.

I am planning on radiant heat throughout the house, with eventual solar thermal and lofty dreams of geotherm and wood fired boiler in the future, and a few other experimental features.

The Basics:

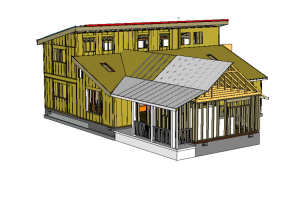

- All 2x6 exterior wall construction, 2x12 vaulted rafters

-1576 sqft first floor

-560 sqft second floor (2132 sqft total), vaulted ceilings 7-10'

-2" closed cell spray foam on all wall and interior ceiling surfaces, augmented with fiberglass.

-Isolated cold deck standing seam roof (plywood layer directly on rafters, 30# felt, 2x3 sleepers, then second layer of ply as roof deck; free vents from outside of soffits, no air flow within structure.

-Rain screen style steel (or maybe Hardee) siding, bug screen vented top and bottom

-Portland, OR Climate zone 8a, if that applied to this conversation

What I'm planning on:

-1st floor: 1/2" O2 barrier Uponor PEX, 8" on center, cast in gyp-crete, 23/32 OSB, Floating rubber-backed carpet squares, circuits are all 150' or less with separate circuits per room (this is 40% installed)

-2nd floor: 1/2" O2 PEX, same layout, but with staple-up aluminum transfer plates. (7) 150' +/- circuits. 5" spacing in bathroom

-Electric backup heat in all spaces (for both quick heat rise per zone and boiler failure.

-Future eventuality of zone controlling room by room via manifold soleniods. I have a plan for a PLC controller that will limit electric heat and manage boiler/valves/recircs.

-NTI Combi Boiler, for heating and domestic.

-Storage tank on heating circuit return, with coil(s) for preheating domestic water/adding solar thermal/Geo/Wood/Thermal mass

-I have a 3 yard void under the fireplace. I'm planning on foam isolating and casting PEX circuits in a 6 ton block of concrete to utilized that space for thermal mass to charge from rooftop solar

-I have site specific design for a rocket-mass style firebox, under the stairs (internal center of the structure). This may also have heating coils built in to transfer directly to thermal mass or into storage tank for dom/heating preheat.

-HRV to service bathroom exhaust and provide air exchange. Hoping to not have to add powered fans, if possible.

So, here's the ask...

I feel a bit overwhelmed in getting the specifics sorted out for equipment needed! I have been doing research for years to try to understand thermal transfer physics and all, and most of my research avails to amazingly differing opinions on what works and what doesn't.

So, any advice about any and all talking points above would be greatly appreciated. Forum links, contractors that could consult, personal experience, BTU calculators or software, really anything.

I did pick up "Heating with Renewable Energy" by John Siegenthaler P.E. at the beginning of this half decade rabbit hole, which has been helpful, yet also above my understanding.

I am a commercial/industrial electrician, and have installed a lot of HVAC control with Siemens and JCI, which is the lions pride of my knowing enough to be dangerous in the realm. Side note, I'm not a Doctor, that's just a nickname that stuck decades ago.

Thank you kindly for your time!