Good evening,

I am a new user but have used your site for reference for years. There are some very knowledgeable people on here. I am now able to officially thank you for all the help in the past.

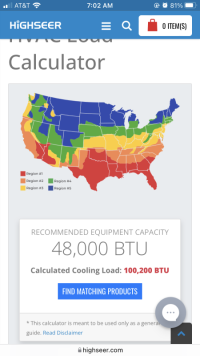

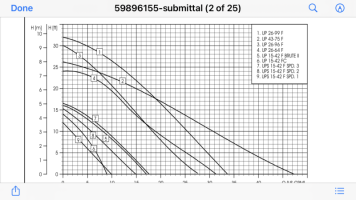

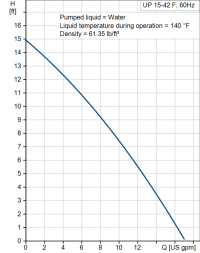

On to the question that finally stumped me and made me sign up. I recently bought a new to me home in Wisconsin. 2700SF heated solely with infloor radiant heat in concrete. 3/4” Grey pex tubing. 8 zones. I have no idea if under the slab is insulated or of the pex spacing in concrete. The house is 30 years old with all original windows, doors, etc. 2x6 exterior walls and there is decent fiberglass insulation in the attic, but I can feel drafts from the windows and doors. The temps have been in the single digits here lately. The house slowly loses heat throughout the night with temps around 65 in the morning and thermostats set to 70. House normally catches back up during the day and the boiler cycles. The furnace runs non stop throughout the night. The radiant in floor system is original to the house but the boiler has been replaced approximately 3-4 years ago with a HydroSmart unit from Menards. My outgoing water temperature is 120° and return is around 90° (Plus or minus 5°). Boiler readout says 2.7GPM. There are two pumps on the system. One fixed and one variable speed with it set on speed 3. I know the previous homeowner installed the system himself. Boiler systems are new (and confusing) to me. I am unconfident the system is sized correctly for the house and/or hooked up correctly. Any advice is appreciated.

I am a new user but have used your site for reference for years. There are some very knowledgeable people on here. I am now able to officially thank you for all the help in the past.

On to the question that finally stumped me and made me sign up. I recently bought a new to me home in Wisconsin. 2700SF heated solely with infloor radiant heat in concrete. 3/4” Grey pex tubing. 8 zones. I have no idea if under the slab is insulated or of the pex spacing in concrete. The house is 30 years old with all original windows, doors, etc. 2x6 exterior walls and there is decent fiberglass insulation in the attic, but I can feel drafts from the windows and doors. The temps have been in the single digits here lately. The house slowly loses heat throughout the night with temps around 65 in the morning and thermostats set to 70. House normally catches back up during the day and the boiler cycles. The furnace runs non stop throughout the night. The radiant in floor system is original to the house but the boiler has been replaced approximately 3-4 years ago with a HydroSmart unit from Menards. My outgoing water temperature is 120° and return is around 90° (Plus or minus 5°). Boiler readout says 2.7GPM. There are two pumps on the system. One fixed and one variable speed with it set on speed 3. I know the previous homeowner installed the system himself. Boiler systems are new (and confusing) to me. I am unconfident the system is sized correctly for the house and/or hooked up correctly. Any advice is appreciated.