jferello

Member

Hey all,

I bought a new house 3 months ago and it came with the following water system.

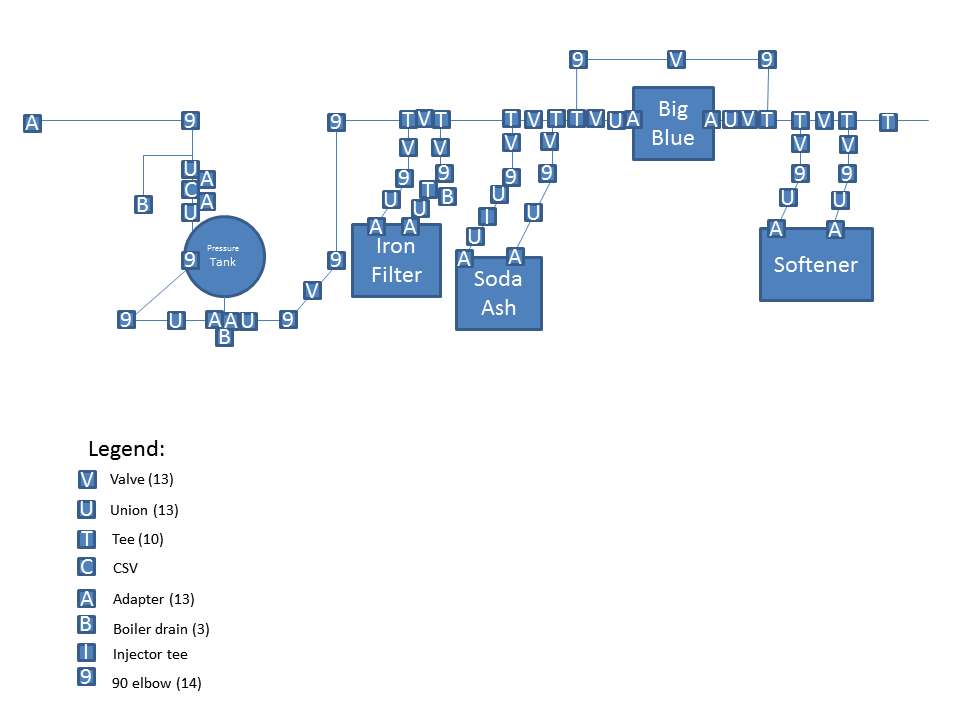

64' well, 48' pump, 20' static, 10+GPM pump -> CSV valve -> 40/60 pressure switch which never drops below 40psi -> 20gal Pressure tank with 35psi of air -> Big blue filter with 5 micron filter -> Autotrol 24k water softener -> Ecosystems iron/sulfer AIV10 -> Soda ash contact contact tank/stenner chemical pump -> inside plumbing fixtures.

The last water test before we bought the house was taken from the valve at the pressure tank:

pH 6.8

Harness 9

TDS 280

Iron 0.6

We do have hydrogen sulfide, hence the Ecosystems filter and if we bypass it we get bad rotten egg smell.

I believe we have clear water iron as the water from the valve near the pressure tank comes out clear then turns reddish after awhile.

On to the issue at hand, we seem to only be getting around 3-5GPM in our house, if we flush a low flow toilet and try to use the kitchen sink at the same time we almost get a dribble. The hose bib outside is after all the equipment and it is pathetic, even with nothing in the house running.

I recently added a CSV valve into the mix since our pump would fill the pressure tank in 30 seconds or less. In adding this valve in I found that our 1" well pipe has been reduced to about 1/2" due to iron build up, not sure how to resolve this.

Anyway, since we have a 20gal tank, it holds about 4.5 gal of water and the pump was able to fill this in about 30 seconds, so we should be getting at least 8GPM to the pressure tank; where we are loosing the other 4GPM is the mystery.

- I have bypassed the Ecosystems filter, same issue, and the Ecosystem is rated for 10+GPM.

- I have changed the filter in the Big Blue, same issue, and the Big Blue is rated for 10+GPM.

- There is nothing to bypass for the Soda Ash system, since its just a contact tank and there is no bypass, not sure this would be the problem anyway though?

- There is no bypass valve installed on the water softener, so I cannot test this. I know the injector screen and injector were just cleaned about 2 months ago. Also, it was rebeded in 2014. Note, the Autotrol does have a flow meter and it does not work, I have tested the probe with a magnet and it works, so I am guessing the turbine in the output tube is not spinning to really dirty, would this cause the lost pressure?

My plan this weekend is to fill a 5gal bucket with our hose and see how long it takes, then I am going to re-plumb the hose bib to the pipe between the pressure tank and the Big Blue, then time the 5gal bucket fill again.

Any other ideas?

Some other random questions:

- Any idea how to clean the 1" pipe from the well head into the house? It should be about 15-20' long. The iron buildup in the pipe is easily moved with a finger.

- Should the Ecosystems be moved in front of the water softener? Since my iron PPM is lower than 1 they might only be using the Ecosystems filter to remove the sulfur.

- Should the hose bib be plumbed before or after the Big Blue?

- Do I even need a water softener with a hardness of 9-10 and iron at 1ppm?

I bought a new house 3 months ago and it came with the following water system.

64' well, 48' pump, 20' static, 10+GPM pump -> CSV valve -> 40/60 pressure switch which never drops below 40psi -> 20gal Pressure tank with 35psi of air -> Big blue filter with 5 micron filter -> Autotrol 24k water softener -> Ecosystems iron/sulfer AIV10 -> Soda ash contact contact tank/stenner chemical pump -> inside plumbing fixtures.

The last water test before we bought the house was taken from the valve at the pressure tank:

pH 6.8

Harness 9

TDS 280

Iron 0.6

We do have hydrogen sulfide, hence the Ecosystems filter and if we bypass it we get bad rotten egg smell.

I believe we have clear water iron as the water from the valve near the pressure tank comes out clear then turns reddish after awhile.

On to the issue at hand, we seem to only be getting around 3-5GPM in our house, if we flush a low flow toilet and try to use the kitchen sink at the same time we almost get a dribble. The hose bib outside is after all the equipment and it is pathetic, even with nothing in the house running.

I recently added a CSV valve into the mix since our pump would fill the pressure tank in 30 seconds or less. In adding this valve in I found that our 1" well pipe has been reduced to about 1/2" due to iron build up, not sure how to resolve this.

Anyway, since we have a 20gal tank, it holds about 4.5 gal of water and the pump was able to fill this in about 30 seconds, so we should be getting at least 8GPM to the pressure tank; where we are loosing the other 4GPM is the mystery.

- I have bypassed the Ecosystems filter, same issue, and the Ecosystem is rated for 10+GPM.

- I have changed the filter in the Big Blue, same issue, and the Big Blue is rated for 10+GPM.

- There is nothing to bypass for the Soda Ash system, since its just a contact tank and there is no bypass, not sure this would be the problem anyway though?

- There is no bypass valve installed on the water softener, so I cannot test this. I know the injector screen and injector were just cleaned about 2 months ago. Also, it was rebeded in 2014. Note, the Autotrol does have a flow meter and it does not work, I have tested the probe with a magnet and it works, so I am guessing the turbine in the output tube is not spinning to really dirty, would this cause the lost pressure?

My plan this weekend is to fill a 5gal bucket with our hose and see how long it takes, then I am going to re-plumb the hose bib to the pipe between the pressure tank and the Big Blue, then time the 5gal bucket fill again.

Any other ideas?

Some other random questions:

- Any idea how to clean the 1" pipe from the well head into the house? It should be about 15-20' long. The iron buildup in the pipe is easily moved with a finger.

- Should the Ecosystems be moved in front of the water softener? Since my iron PPM is lower than 1 they might only be using the Ecosystems filter to remove the sulfur.

- Should the hose bib be plumbed before or after the Big Blue?

- Do I even need a water softener with a hardness of 9-10 and iron at 1ppm?

Last edited: