Mike Hawk

New Member

Valve: Fleck 7000SXT

Water source: City water (river), Oklahoma RWD#5

Tank size: 12x48

GPG: 8-13

Gallons used per month: 8,000 (ouch). 2 adults and 2 kids. Wife and one kid take ~1-2 baths per week. Shower daily.

Our system:

When I ordered this system back in Q4 2015 I had a 64,000 system setup from the seller. 'Murcia? Bigger is better? 8% resin imported from out of USA, ie probably really junk stuff that all the online sellers sell. Water pressure was great for several years. A few years later we got a significant decrease in water pressure. I had never cleaned or dosed cleaner in the system. Just added cheap salt (ie no iron remover salt). My bad. Live and learn.

The system has been in bypass mode for ~2 years now. Started it back up the other day and it seemed to have great pressure for a bit but then after a day or so pressure was down again. I'm hoping/assuming it's just fouled resin and I just need to remove and replace the resin? I'll rebuild the valve if I have to but I've never done a rebuild. Hope it's not the valve since it had good pressure for a day or so. (shrug)

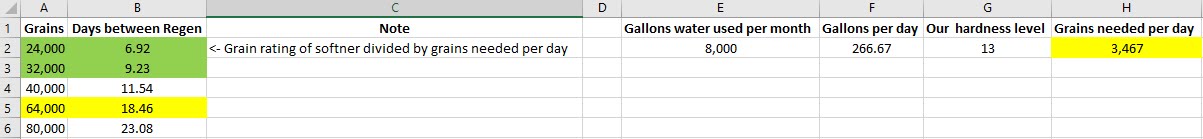

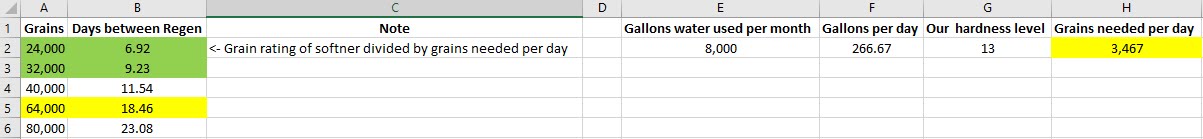

With the size of the current system (64,000) and our usage, it looks like it was regenerating every ~18 days. Probably not good for the life of the resin from what I'm reading and that 7 days is a better target? Looks like I could squeak by on a 24,000 grain system? 24,000 / 3,467 grains needed per day = 6.92 days between regen?

Tank didn't have a gravel bed. Guessing 1.0cf of 10% resin should be good enough after I reset the Fleck settings? Is a 12x48 resin tank big enough for us? How much 10% resin do I need? Which are reputable brands/sellers of resin? Where to get? Also, what sort of gravel do I need to get and how much?

It was hard to get a contractor out here, I guess they only like do do new installs? Finally got at least one plumber out here and he took one look at our system and poo poo'd a resin removal / re-bed that we were asking for and said our system wasn't big enough and needed a 72,000 grain system. IE he just wanted to do a complete removal of all equipment and replace everything. I'm taking his input with a grain of salt though.

Speaking of salt, the salt turned orange while not being used for 2+ years. I'm assuming that's iron/rust? Remove/replace the salt or throw in some iron out or better iron salt?

Thanks in advance!

-Mike

Water source: City water (river), Oklahoma RWD#5

Tank size: 12x48

GPG: 8-13

Gallons used per month: 8,000 (ouch). 2 adults and 2 kids. Wife and one kid take ~1-2 baths per week. Shower daily.

Our system:

When I ordered this system back in Q4 2015 I had a 64,000 system setup from the seller. 'Murcia? Bigger is better? 8% resin imported from out of USA, ie probably really junk stuff that all the online sellers sell. Water pressure was great for several years. A few years later we got a significant decrease in water pressure. I had never cleaned or dosed cleaner in the system. Just added cheap salt (ie no iron remover salt). My bad. Live and learn.

The system has been in bypass mode for ~2 years now. Started it back up the other day and it seemed to have great pressure for a bit but then after a day or so pressure was down again. I'm hoping/assuming it's just fouled resin and I just need to remove and replace the resin? I'll rebuild the valve if I have to but I've never done a rebuild. Hope it's not the valve since it had good pressure for a day or so. (shrug)

With the size of the current system (64,000) and our usage, it looks like it was regenerating every ~18 days. Probably not good for the life of the resin from what I'm reading and that 7 days is a better target? Looks like I could squeak by on a 24,000 grain system? 24,000 / 3,467 grains needed per day = 6.92 days between regen?

Tank didn't have a gravel bed. Guessing 1.0cf of 10% resin should be good enough after I reset the Fleck settings? Is a 12x48 resin tank big enough for us? How much 10% resin do I need? Which are reputable brands/sellers of resin? Where to get? Also, what sort of gravel do I need to get and how much?

It was hard to get a contractor out here, I guess they only like do do new installs? Finally got at least one plumber out here and he took one look at our system and poo poo'd a resin removal / re-bed that we were asking for and said our system wasn't big enough and needed a 72,000 grain system. IE he just wanted to do a complete removal of all equipment and replace everything. I'm taking his input with a grain of salt though.

Speaking of salt, the salt turned orange while not being used for 2+ years. I'm assuming that's iron/rust? Remove/replace the salt or throw in some iron out or better iron salt?

Thanks in advance!

-Mike

Last edited: