Midway

New Member

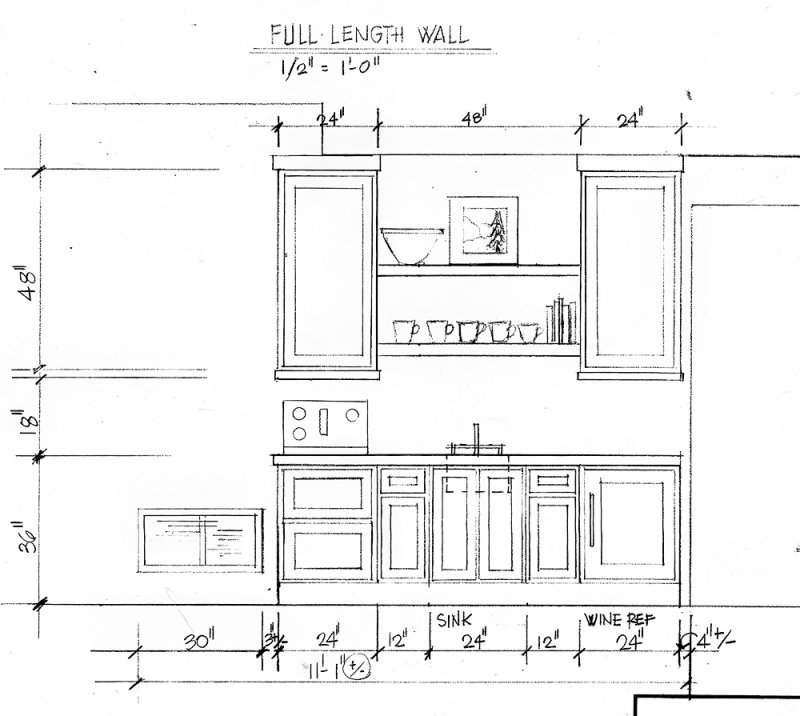

We are adding a coffee/wine bar and I need to at least rough-in the plumbing for the sink. I also want to connect a cold-water line and drain for an espresso machine. I’ve attached pictures of where the coffee bar will be installed and the crawl space area below. There is a small bathroom behind the same wall but the plumbing is on a different wall. The hot water heater and main water line is very close.

I haven’t decided if I want to complete the installation or hire a plumber but since the coffee bar is being installed December 7th I want to get the hot and cold water lines put in which will require cutting out some wallboard and drilling the required holes to feed the drain and supply lines down into the crawl space. I’d leave as much extra as necessary and cut and add fittings later. Assuming I hire a plumber, what and how should I proceed to allow bar installation and to make the final connections for a plumber strait forward?

Thank you.

I haven’t decided if I want to complete the installation or hire a plumber but since the coffee bar is being installed December 7th I want to get the hot and cold water lines put in which will require cutting out some wallboard and drilling the required holes to feed the drain and supply lines down into the crawl space. I’d leave as much extra as necessary and cut and add fittings later. Assuming I hire a plumber, what and how should I proceed to allow bar installation and to make the final connections for a plumber strait forward?

Thank you.

Last edited: