Jaylivi

Member

Good mornning,

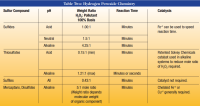

I finally installed a softener and KL backwashing system with hydrogen peroxide injection. The tank for the hydrogen peroxide solution is quite large and I believe I need to mix it with water, but how do I know how much water to use with one gallon of nuetra sul 7% solution?

My water:

ph 7.8

H 400 mg/l

iron 2.61

sulfate 52.8

nitrate .15

So, do I dilute the 7% solution in the holding tank? Also, what is the easiest way to change how much I soften the water?

Thanks,

Jay

I finally installed a softener and KL backwashing system with hydrogen peroxide injection. The tank for the hydrogen peroxide solution is quite large and I believe I need to mix it with water, but how do I know how much water to use with one gallon of nuetra sul 7% solution?

My water:

ph 7.8

H 400 mg/l

iron 2.61

sulfate 52.8

nitrate .15

So, do I dilute the 7% solution in the holding tank? Also, what is the easiest way to change how much I soften the water?

Thanks,

Jay