GianniD

New Member

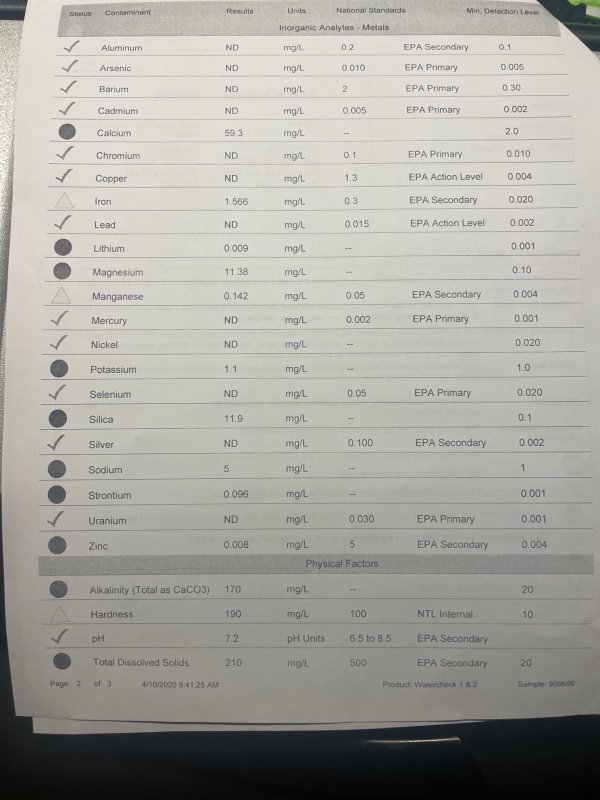

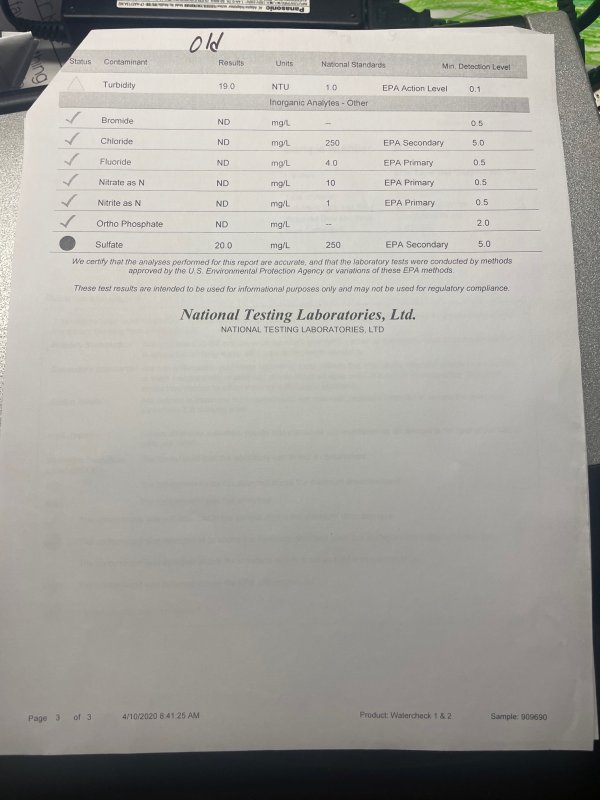

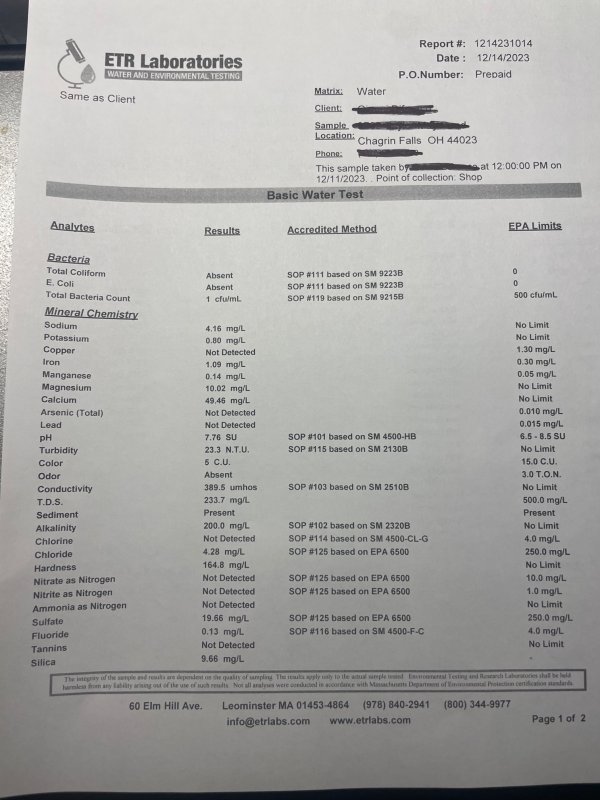

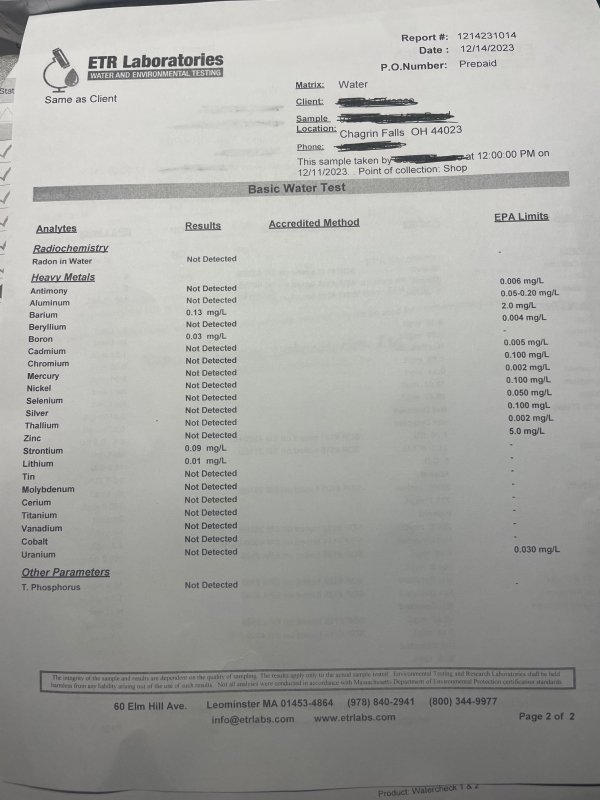

Can use some help with the water treatment system. I had a house built over 3 years ago and based on the old water test attached, the salesman at Nelsen recommended a Katalox Media filter for the iron/sediment and a water softener for the iron. I ended up installing the system pictured and have noticed the clear pex turning red between the Katalox and the water softener. I'm also starting to see some mild staining on the toilets and sink. The Katalox filter doesn't seem like it's removing the Iron based on the red in the line and I figure the softener is doing all the work.

Currently I have the water softener set to regenerate on demand but I have it set to override every 8 days as it never uses the water required to make it regenerate sooner based on water usage. I occasional add Rust out or Resin cleaner about every month.

I'm not sure what I should do with the Katalox filter. I have taken the head apart and made sure it was clean and all seemed ok. I'm wondering if the media went bad and should be replaced. I'm not even sure I want to replace the media if it's going to only last 3 years. I did like the ideal of the Katalox filter as it acts as a sediment filter and iron remover but it's clearly not working now.

My thought is the scrap the Katalox filter all together and put a 20 inch big blue cartridge filter in its place and let the softener do the work with more frequent regeneration. Or is it possible to load the cabinet of the Katalox filter with a different media and keep it in place?

I installed this equipment myself and we put in a few pieces of treatment equipment a year. I'm a excavating contractor and offer this service when we install well equipment. I usually just sent out the water to get tested and forward the test to my salesman at Nelsen. Doesn't seem like his recommendation was good on this one. Thoughts?

Currently I have the water softener set to regenerate on demand but I have it set to override every 8 days as it never uses the water required to make it regenerate sooner based on water usage. I occasional add Rust out or Resin cleaner about every month.

I'm not sure what I should do with the Katalox filter. I have taken the head apart and made sure it was clean and all seemed ok. I'm wondering if the media went bad and should be replaced. I'm not even sure I want to replace the media if it's going to only last 3 years. I did like the ideal of the Katalox filter as it acts as a sediment filter and iron remover but it's clearly not working now.

My thought is the scrap the Katalox filter all together and put a 20 inch big blue cartridge filter in its place and let the softener do the work with more frequent regeneration. Or is it possible to load the cabinet of the Katalox filter with a different media and keep it in place?

I installed this equipment myself and we put in a few pieces of treatment equipment a year. I'm a excavating contractor and offer this service when we install well equipment. I usually just sent out the water to get tested and forward the test to my salesman at Nelsen. Doesn't seem like his recommendation was good on this one. Thoughts?