A while back I posted about water continuing to flow down the drain line after some (but not all) regens. The advice was that there were some known bad 5810 seal and spacers out there and that was my likely culprit so I ordered Part #61956-01.

After procrastinating a while, I replaced the set (piston and seal/spacer cage) about a month ago. Indeed during disassembly I found the top of the piston was broken. My concern at the time was that despite a thorough (but not tear-down) search, I could only find one piece of the broken piston - I worried the others could potentially still be inside the machine and cause issues. The initial regen and the 1 or two since then went fine as far as I could tell (no leaks/continued drainage, and water was soft). So I kept my fingers crossed.

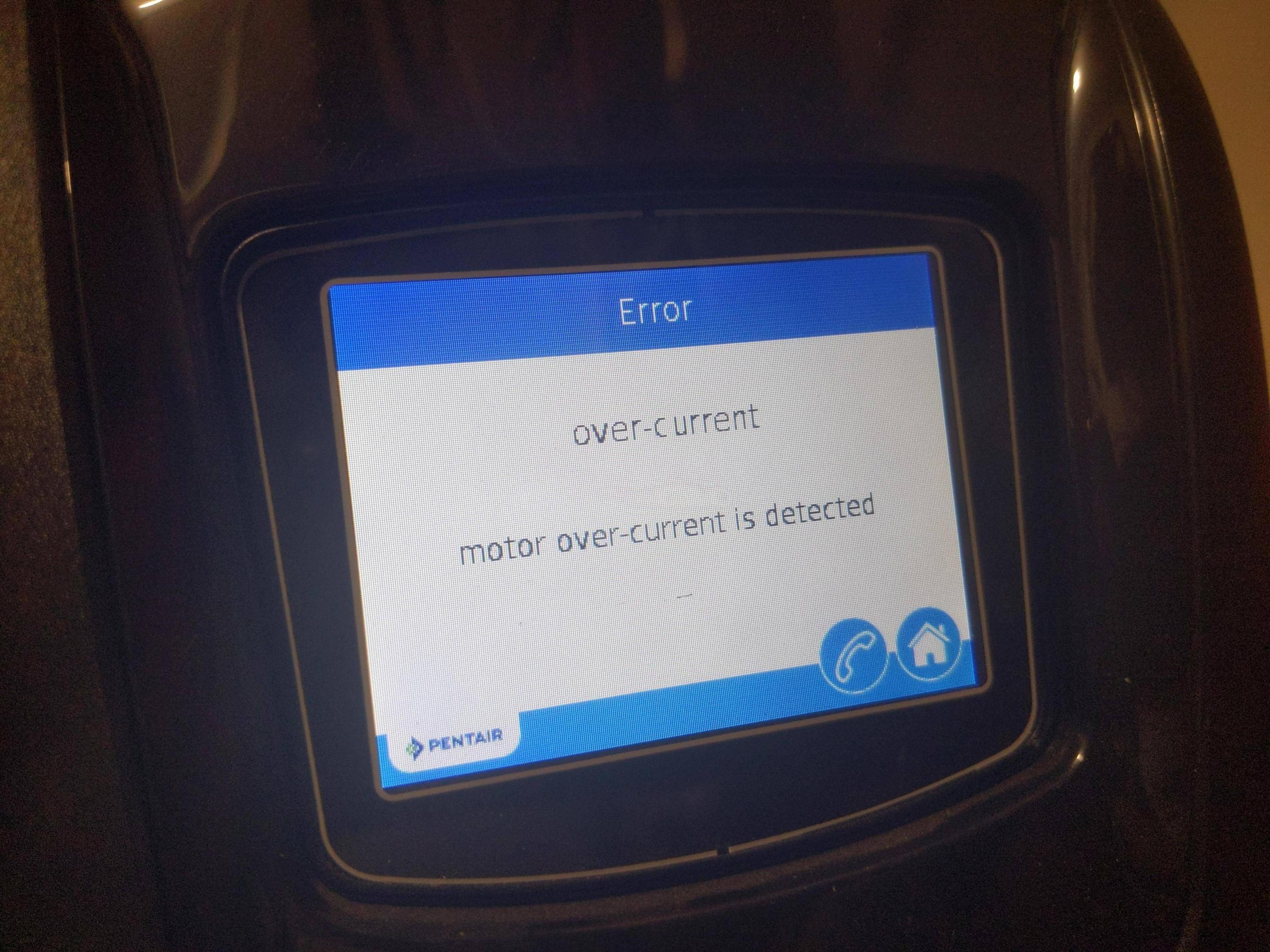

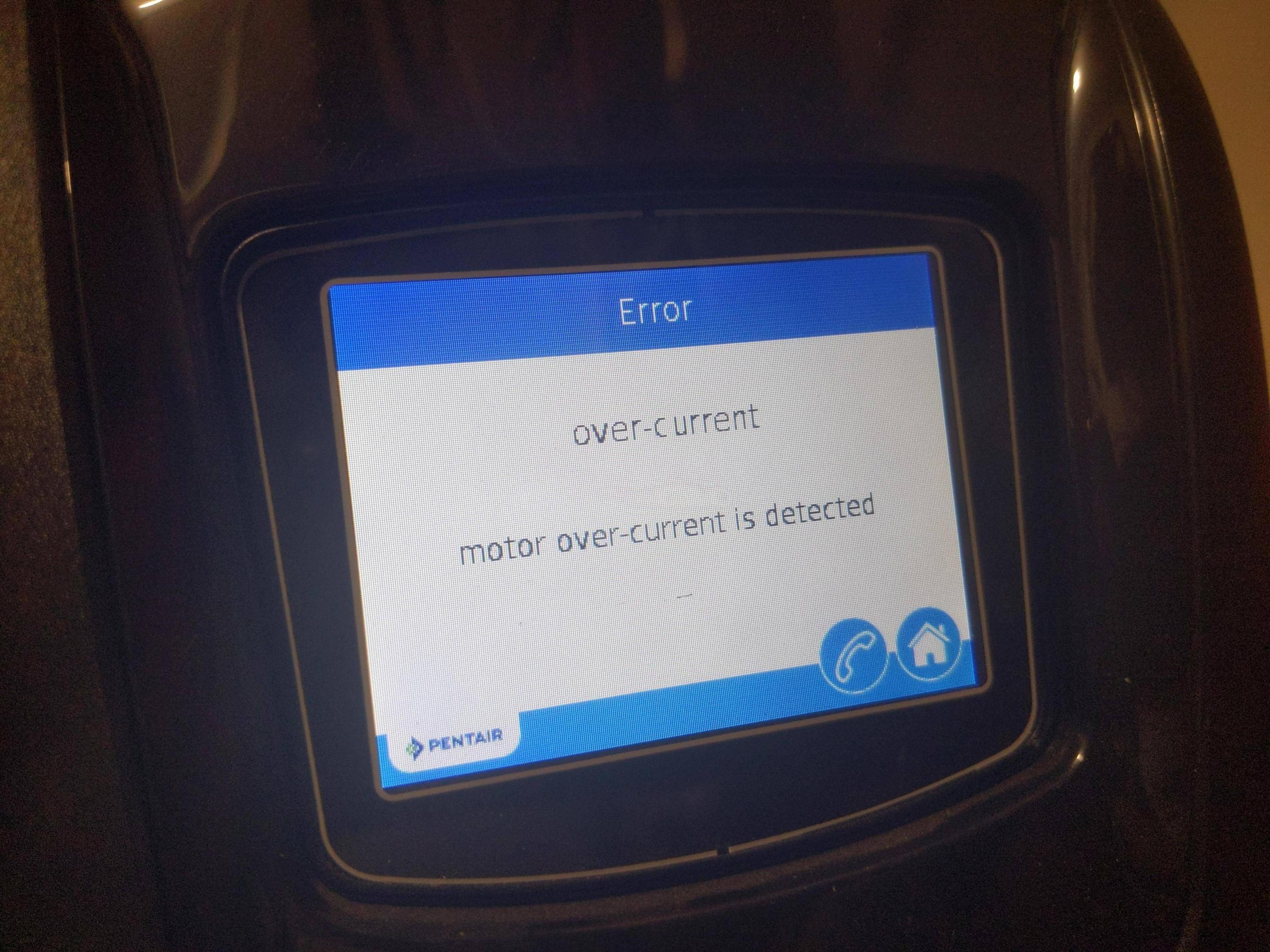

Today the machine tried to do a regen and I was inside the house and noticed the same symptom as before, water continuing to run down the drain for way too long. I went to check the machine and this time I saw the red triangle and error message "over-current, motor over-current is detected". This error never happened before. I hit the home button and hit the manual regen button and the valve made a very loud and very bad sounding repetitive clicking noise for maybe 5-10 seconds. I was headed to unplug it when it stopped. The error message had again appeared on the screen.

See attached pics.

Thoughts?

Do you agree with my suspicion that a small piece of the broken piston may be jamming something internal?

Any links / tutorials / videos on a total and complete teardown of a 5810? (if needed)

After procrastinating a while, I replaced the set (piston and seal/spacer cage) about a month ago. Indeed during disassembly I found the top of the piston was broken. My concern at the time was that despite a thorough (but not tear-down) search, I could only find one piece of the broken piston - I worried the others could potentially still be inside the machine and cause issues. The initial regen and the 1 or two since then went fine as far as I could tell (no leaks/continued drainage, and water was soft). So I kept my fingers crossed.

Today the machine tried to do a regen and I was inside the house and noticed the same symptom as before, water continuing to run down the drain for way too long. I went to check the machine and this time I saw the red triangle and error message "over-current, motor over-current is detected". This error never happened before. I hit the home button and hit the manual regen button and the valve made a very loud and very bad sounding repetitive clicking noise for maybe 5-10 seconds. I was headed to unplug it when it stopped. The error message had again appeared on the screen.

See attached pics.

Thoughts?

Do you agree with my suspicion that a small piece of the broken piston may be jamming something internal?

Any links / tutorials / videos on a total and complete teardown of a 5810? (if needed)