WX4SNO

New Member

Hello all!

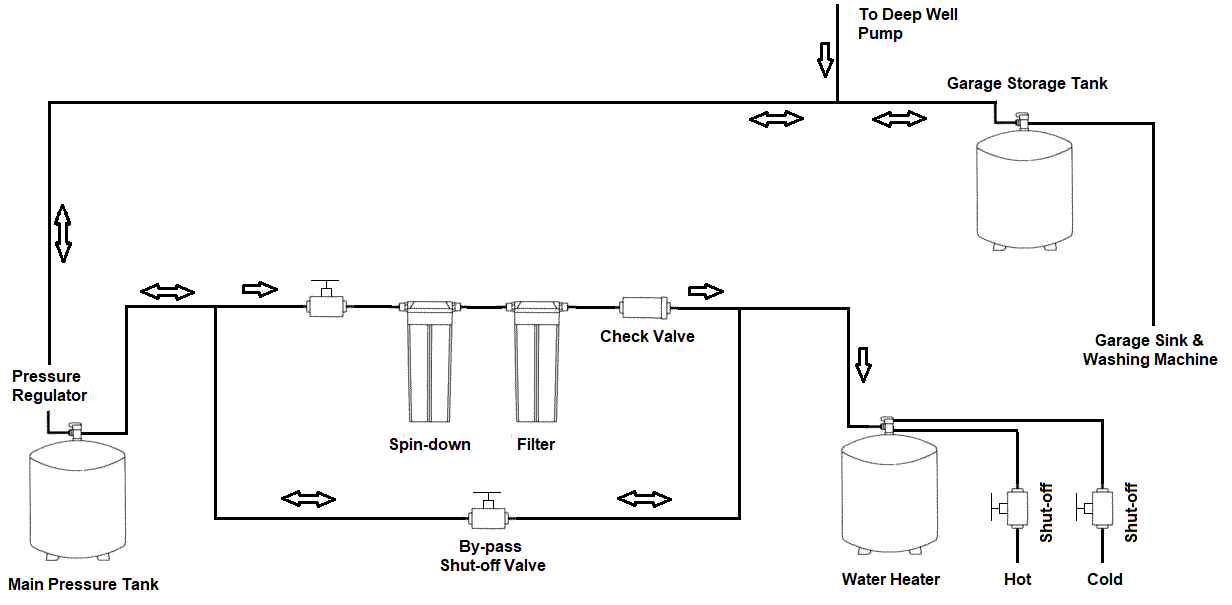

New to the forum but have been reading several posts about check valves and where they are and are not acceptable to be placed. I have been dealing with murky water since we built our house back in 2012. The water is not only murky, at times it is down-right brick red in color, but usually only this bad when I have to turn off the power to the deep well pump and drain the lines for a repair or addition. We currently don't have any filtration on our water so I've decided to do something about that. Here is what I have come up with.

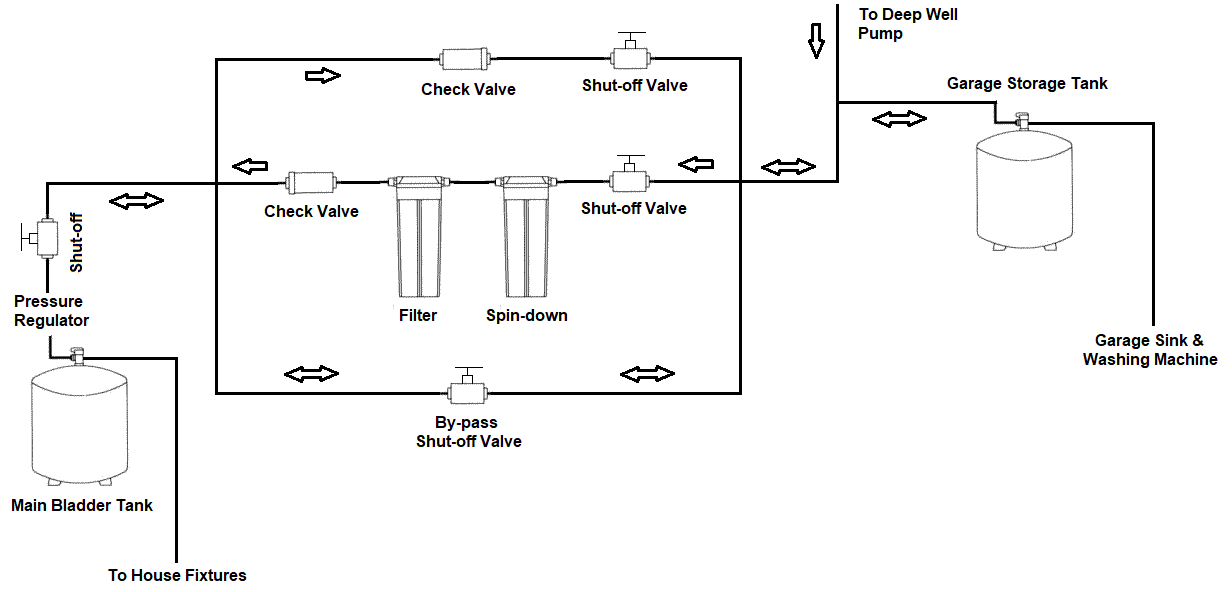

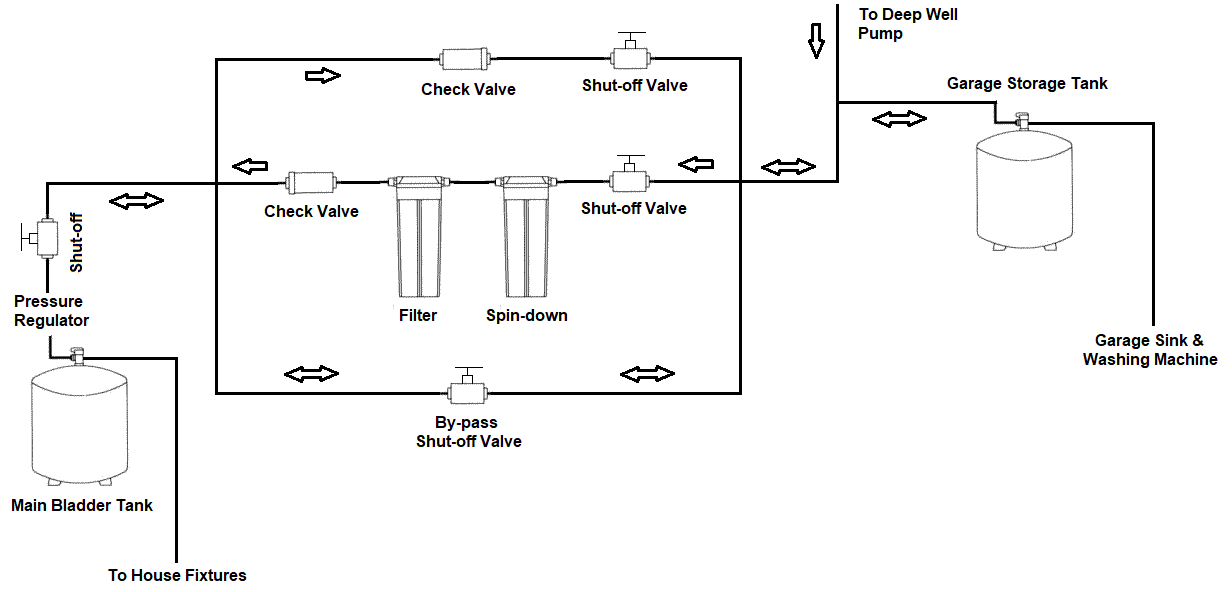

Our submersible well pump is at ~420 feet deep and as far as I know the only check valve on it is within the pump. We have a new garage where I have a second 44-gal bladder tank that doesn't have a pressure switch attached; this is for additional storage to help keep the pump from kicking on so often. I will be putting our washer and dryer in the garage, along with a sink. Anyhow, back to filters. Since the water pressure can flow both to and from the main bladder tank to the garage tank and everywhere in between, I thought I might need to put a check valve on the spin-down and water filter branch line to prevent back-washing the filter every time water needs to flow to the garage end. This allows the water to flow through the filter the right way, then a second branch with another check valve will allow water to by-pass the filter and proceed to the garage. A third branch at the bottom is a simple by-pass shut-off valve to allow for maintenance on the other two lines and will be closed most of the time. The filters and check valves will be placed indoors in the basement next to the pressure tank and before the regulator and regulator shut-off valve. Once I get the washer and sink installed in the garage, I will likely add this same setup with filters and check valves right before the water goes into the storage tank out there.

Is this an acceptable setup and safe to operate? What is the best check valve I can get for this setup? It would need to be one-size up from my line which is a 1-inch poly main, so I'l like a 1-1/4 inch valve. Are there some online I can order for delivery that you all would highly recommend??

I appreciate the help folks!

New to the forum but have been reading several posts about check valves and where they are and are not acceptable to be placed. I have been dealing with murky water since we built our house back in 2012. The water is not only murky, at times it is down-right brick red in color, but usually only this bad when I have to turn off the power to the deep well pump and drain the lines for a repair or addition. We currently don't have any filtration on our water so I've decided to do something about that. Here is what I have come up with.

Our submersible well pump is at ~420 feet deep and as far as I know the only check valve on it is within the pump. We have a new garage where I have a second 44-gal bladder tank that doesn't have a pressure switch attached; this is for additional storage to help keep the pump from kicking on so often. I will be putting our washer and dryer in the garage, along with a sink. Anyhow, back to filters. Since the water pressure can flow both to and from the main bladder tank to the garage tank and everywhere in between, I thought I might need to put a check valve on the spin-down and water filter branch line to prevent back-washing the filter every time water needs to flow to the garage end. This allows the water to flow through the filter the right way, then a second branch with another check valve will allow water to by-pass the filter and proceed to the garage. A third branch at the bottom is a simple by-pass shut-off valve to allow for maintenance on the other two lines and will be closed most of the time. The filters and check valves will be placed indoors in the basement next to the pressure tank and before the regulator and regulator shut-off valve. Once I get the washer and sink installed in the garage, I will likely add this same setup with filters and check valves right before the water goes into the storage tank out there.

Is this an acceptable setup and safe to operate? What is the best check valve I can get for this setup? It would need to be one-size up from my line which is a 1-inch poly main, so I'l like a 1-1/4 inch valve. Are there some online I can order for delivery that you all would highly recommend??

I appreciate the help folks!