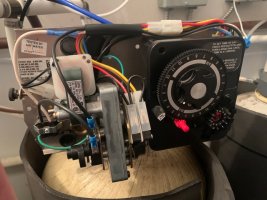

I added the injector to my Fleck valve. Looking at the injector I can see how it works. I run it and sucks during the draw cycle, but also spits out during other cycles, so to manually prevent this, and to control the amount of additive sucked up, I also have a little quick connect valve in the line. I suck in about a cup of bleach into the 12x52 iron filter tank during draw, turn the valve off, and have it sitting there (in bypass) for 24 hours. (I understand if I wanted to do this systematically with each backwash I would need to add the brine valve piston to the system, to manage sucking/spitting, and size all the little restrictors appropriately for correct dosing)

My Katalox media is all 'clumped up' (during backwash there are only wisps in one corner). I've read several threads on this board where people had this problem and battled with increasing backwash and manually attacking it. I'm hoping soaking in bleach will loosen it up in situ. Blowing out and capturing some media I can see it is black (see photo). Adding bleach changes it to tan color. The same effect can be obtained by aerating and waiting several hours. I don't know what the natural color of katalox is. I hypothesize that the black is a coating of depositing iron (2ppm) or manganese (0.5 ppm), and it is this coating that glues the Katalox together. So could the root cause of clumping be lack of dissolved air not backwash ?