Hi , I did a search but opinions are varying.

My new softener (2.5 Cubic feet) was installed in Nov 2022. I have 0.12 ppm iron in raw water but by opening the Big Blue 20 sediment filter that is installed before the softener, I found that there is rust caught by the pre filter but some of this might be reaching to the softer resin. I have two BigBlue 20 pre filters. One is washable pleated 10 microns and other non washable 5 micron sediment filter.

So I want to use some sort of resin cleaner. By reading the forum, I have concluded that I will use Food grade Citric Acid and not the Iron Out.

The supply I am getting is a bag of 10 lbs fine granular Citric Acid for $50 Canadian. THis should last me 5 months so $10 per month . Not bad

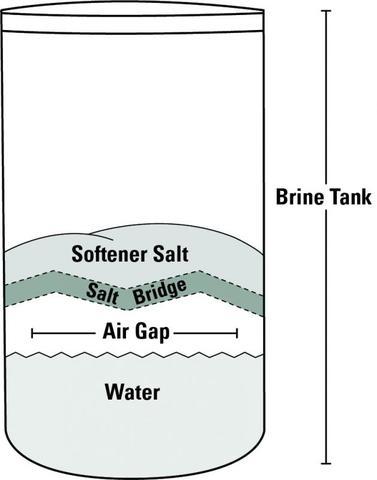

Application - How Much to use? Is 2 Lbs per month good enough? and how to dump? normally I keep Salt in the tank a few inches above brine level. So when I want to put Citric Acid, should I let the salt go below the water level and sprinkle 2 lbs of Citirc acid at the top layer of the Brine?

Please suggest

My new softener (2.5 Cubic feet) was installed in Nov 2022. I have 0.12 ppm iron in raw water but by opening the Big Blue 20 sediment filter that is installed before the softener, I found that there is rust caught by the pre filter but some of this might be reaching to the softer resin. I have two BigBlue 20 pre filters. One is washable pleated 10 microns and other non washable 5 micron sediment filter.

So I want to use some sort of resin cleaner. By reading the forum, I have concluded that I will use Food grade Citric Acid and not the Iron Out.

The supply I am getting is a bag of 10 lbs fine granular Citric Acid for $50 Canadian. THis should last me 5 months so $10 per month . Not bad

Application - How Much to use? Is 2 Lbs per month good enough? and how to dump? normally I keep Salt in the tank a few inches above brine level. So when I want to put Citric Acid, should I let the salt go below the water level and sprinkle 2 lbs of Citirc acid at the top layer of the Brine?

Please suggest