excellrec

New Member

Hi all,

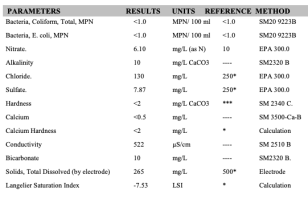

I've corrosive well water that I am trying to remedy. It completely ate an anode rod in a new water heater in less than a year, though all the plumbing in the house is PEX so there haven't been any other obvious problems. I've attached a certified lab report from a test earlier this week, pH was measured at 5.5. LSI is -7.52 and would pH correction be the most effective way to reduce corrosiveness of the water?

I've looked through the forum and elsewhere and it seems increasing pH through soda ash injection might be the best way to bring this low ph to a consistent neutral, but would be curious if others disagree and why. I'm put off by corosex and the like because of poor pH stability. I'd like to do the install myself and am wondering where is a decent place to get components for the system? Since these systems are known to be high maintenance I prioritize reliability and effectiveness over trying to save a few bucks. Current system is well pump -> pressure tank -> UV light -> Sediment Filter -> carbon filter -> lead filter -> rest of the house. I believe between pressure tank and UV light is the best place for the injection pump?

Thank you in advance!

I've corrosive well water that I am trying to remedy. It completely ate an anode rod in a new water heater in less than a year, though all the plumbing in the house is PEX so there haven't been any other obvious problems. I've attached a certified lab report from a test earlier this week, pH was measured at 5.5. LSI is -7.52 and would pH correction be the most effective way to reduce corrosiveness of the water?

I've looked through the forum and elsewhere and it seems increasing pH through soda ash injection might be the best way to bring this low ph to a consistent neutral, but would be curious if others disagree and why. I'm put off by corosex and the like because of poor pH stability. I'd like to do the install myself and am wondering where is a decent place to get components for the system? Since these systems are known to be high maintenance I prioritize reliability and effectiveness over trying to save a few bucks. Current system is well pump -> pressure tank -> UV light -> Sediment Filter -> carbon filter -> lead filter -> rest of the house. I believe between pressure tank and UV light is the best place for the injection pump?

Thank you in advance!