Assquatch

New Member

Hello,

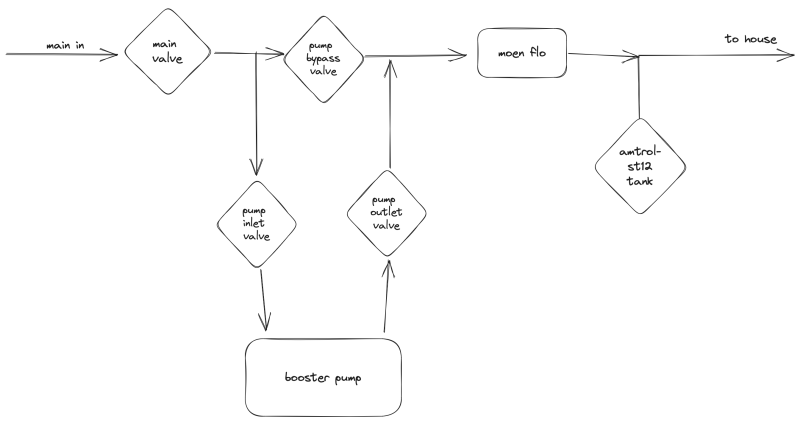

I added a Scala2 and a moen Flo to my system. I had a highly elevated home (3-4 stories from main to living space). Once I added the pump, pressure was great, but I observed fluctuating and creeping up of pressure through the flo. I just added an expansion tank to the cold line after the pump and moen flo, but my pump is short cycling. It seems to pump to its upper limit, and then ride off the pressure accumulated in the tank, and then cycle back on when it reaches the lower limit. I understand there is a 10psi threshold that trigger it on and off.

I think I may have a problem with my tank pre-charges but I can't figure it out. Scala2 is configured to run at 2nd highest setting of 5 bar = 72.52 psi. I set the Scala2 interior tank to 49psi (70% of the outlet pressure, per the manual) I also set the external expansion tank to the same.

Please let me know if you can think of any reason for this, things to check etc.

I added a Scala2 and a moen Flo to my system. I had a highly elevated home (3-4 stories from main to living space). Once I added the pump, pressure was great, but I observed fluctuating and creeping up of pressure through the flo. I just added an expansion tank to the cold line after the pump and moen flo, but my pump is short cycling. It seems to pump to its upper limit, and then ride off the pressure accumulated in the tank, and then cycle back on when it reaches the lower limit. I understand there is a 10psi threshold that trigger it on and off.

I think I may have a problem with my tank pre-charges but I can't figure it out. Scala2 is configured to run at 2nd highest setting of 5 bar = 72.52 psi. I set the Scala2 interior tank to 49psi (70% of the outlet pressure, per the manual) I also set the external expansion tank to the same.

Please let me know if you can think of any reason for this, things to check etc.