You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fleck 7000 64k unit replacing resin

- Thread starter Silversaver

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Bannerman

Well-Known Member

The settings suggested, is for 2 ft3 of resin. If there is only 1ft3 resin in the tank, it will continue to not provide the quantity and quality of soft water you are expecting.C = 48.0 ; capacity in 1000 grains

The control valve calculates gallons based on the settings programmed. It doesn't know how much resin is within the tank, only the Capacity and Hardness settings programmed. If the Capacity or Hardness setting is incorrect, it will continue to calculate gallons remaining based on incorrect data.With hardness setting at 25, each regeneration I’m getting about close to 1700 gallons.

Your current settings are 48,000 grains Capacity / 25 gpg Hardness = 1,920 gallons - 15% Reserve Allowance (1920 gals - 15%) = 1632 gallons softening capacity available directly following regeneration.

As previously stated, 1ft3 resin cannot provide 48K grains (1632 gallons) of softening Capacity.

There are benefits and no drawbacks in installing bedding gravel in any size softener tank. One benefit is the gravel provides a barrier against resin loss into the plumbing system in the event of a compromised bottom basket.understand it is recommend use gravel for tank greater 12”.

I see your 'technician' suggested modifying your softener to remove VOCs and chemical compounds, likely be adding some amount of granular activated carbon (GAC) into the resin tank. Strongly advise against doing this as carbon and softening resin backwash requirements are completely different, and carbon also has a significantly shorter usable lifespan.

While GAC is a fantastic filtration media, it should not be mixed directly with softener resin but is to remain separated, usually by installing within its own tank equipped with a backwashing control valve that is configured appropriately for that media.

Last edited:

Sponsor

Paid Advertisement

The settings suggested, is for 2 ft3 of resin. If there is only 1ft3 resin in the tank, it will continue to not provide the quantity and quality of soft water you are expecting

I may have misinterpreted this statement: "If he does put 2 bag of resin, then why the water will not stays soft through out the whole cycle? With hardness setting at 25, each regeneration I’m getting about close to 1700 gallons."

I took that as meaning that after 1700 gallons used, the water was no longer soft. Instead OP may have been saying that the display shows about 1700 gallons remaining after each regeneration, but the water turns hard after 750 gallons of that have been used.

In #15, I said "If you have an actual 25 grains of hardness, you are lucky to get 1700 gallons of softening. So answer the two questions, and we can discuss." OP did not object, but maybe OP did not understand what I was trying to say.

So let me say this: if the water stops being soft after 000 or 800 gallons have been used, then that would support the theory of 1 cuft. I should have been more clear.

Silversaver

Member

Thanks for the inputs guys, you guys are great.

To be honest, I am running out of soft water before the regeneration + water not soft enough (BF set at 28). I am basing on the memory as I recall the service guy only replace with one bag of resin, that's why I start this thread. As I look up and found the text message I did indicate it needs 2 bags of resin. I am sure he has acknowledge that. I wasn't there the whole time watching him but I did only see one empty bag of resign. I do think he is a nice guy (installer) and I don't think he will short me a bag of resin.

I did 3 regenerations in the past 10 days (last one is yesterday afternoon), making sure the salt level is there and BF set at 32. I set the hardness at 27 which it should deliver about 1500s gallon of soft water if everything is right including 2ft3 of resin in the tank. I also add 1/2 gallon of water mixing with Iron Out to the brine tank before regeneration yesterday.

As result of this morning shower, the water is very smooth. (the hot water tank has be empty out with soft water after 2 showers last night) I'll monitoring the water in the next 7 days.

To be honest, I am running out of soft water before the regeneration + water not soft enough (BF set at 28). I am basing on the memory as I recall the service guy only replace with one bag of resin, that's why I start this thread. As I look up and found the text message I did indicate it needs 2 bags of resin. I am sure he has acknowledge that. I wasn't there the whole time watching him but I did only see one empty bag of resign. I do think he is a nice guy (installer) and I don't think he will short me a bag of resin.

I did 3 regenerations in the past 10 days (last one is yesterday afternoon), making sure the salt level is there and BF set at 32. I set the hardness at 27 which it should deliver about 1500s gallon of soft water if everything is right including 2ft3 of resin in the tank. I also add 1/2 gallon of water mixing with Iron Out to the brine tank before regeneration yesterday.

As result of this morning shower, the water is very smooth. (the hot water tank has be empty out with soft water after 2 showers last night) I'll monitoring the water in the next 7 days.

The question is, how many gallons of water have been used before the hardness rises over 1 grain or before you detect hardness thru lathering or whatever metric you use?Thanks for the inputs guys, you guys are great.

To be honest, I am running out of soft water before the regeneration + water not soft enough (BF set at 28). I am basing on the memory as I recall the service guy only replace with one bag of resin, that's why I start this thread.

700 gallons? 1400 gallons? What?

Silversaver

Member

I have not use hardness tester, but base on how smooth of water felt.The question is, how many gallons of water have been used before the hardness rises over 1 grain or before you detect hardness thru lathering or whatever metric you use?

700 gallons? 1400 gallons? What?

All I'm doing now is eliminate and narrow down for fact finding before next step

Last edited:

So you know where the gallons on the display started after regen. As soon as you detect the softness is below par, go read the display. Take the difference.

A Hach 5-B test is useful to measure your actual hardness coming in and to measure the residual hardness.

A Hach 5-B test is useful to measure your actual hardness coming in and to measure the residual hardness.

Silversaver

Member

Yes, I do. Thanks for the tipsSo you know where the gallons on the display started after regen. As soon as you detect the softness is below par, go read the display. Take the difference.

A Hach 5-B test is useful to measure your actual hardness coming in and to measure the residual hardness.

Silversaver

Member

I believe I do have to order a bag of resin. People been talking about 10% crosslink resin, but I can only find Purolite which I believe it is only 8% crosslink. Any suggest place to order the resin?

Silversaver

Member

Hi,The total (maximum) capacity for 1ft3 resin is 32,000 grains. To regenerate all 32K capacity for 1ft3, will require 18-20 lbs salt each cycle. Your 28-minute BF setting will dissolve 21 lbs salt, and the 32-minute setting will dissolve 24 lbs salt. The additional salt in excess of 18-20 lbs, will not provide softer water but will only be wasted.

2ft3 resin will fill your 12X52 tank to approx 2/3 of the tank height, but with only 1ft3, the tank will only be filled to ~1/3 of the tank height, which will provide insufficient resin depth for hardness removal to fully occur.

Programming the controller to regenerate when it calculates 48K grains has been depleted, will not extend soft water delivery to the next subsequent regeneration as the maximum capacity for 1ft3 resin is only 32K grains, so the resin's capacity will be exhausted long before regeneration will occur.

The soft water that will be initially provided from the 32K that was regenerated, will be of low quality due to the amount of hardness leakage resulting from insufficient resin depth. Adding a further 1ft3 to the 1ft3 resin already within the tank, will increase the resin depth which will improve soft water quality, and the additional capacity from 2ft3, will provide 48K of usable capacity between regen cycles.

Although the total capacity for 2ft3 is 64K, salt efficiency will be increased by topping-up capacity when 48K has been depleted, as only 16 lbs salt will be needed (48,000 / 16lbs = 3,000 grains per lb efficiency).

Your softener's label specifies it is equipped with a 2.4 GPM DLFC (drain line flow control). To ensure sufficient resin lift and expansion during Backwash, a 2.4 GPM DLFC is usually appropriate for a 10" diameter softener, and 3.0 GPM for a 12" tank. As you are located in California where your incoming water maybe warmer than most areas, your softener may require a DLFC restrictor that exceeds 3.0 GPM depending on the water temperature.

I’ll be working on my Fleck 7000 64k unit. I recall you mention about the 2.4GPM DLFC been too small. Should I replace with the correct size Button to 3.0GPM or larger?

Thanks

Attachments

3.5 GPMHi,

I’ll be working on my Fleck 7000 64k unit. I recall you mention about the 2.4GPM DLFC been too small. Should I replace with the correct size Button to 3.0GPM or larger?

Silversaver

Member

Thank you!

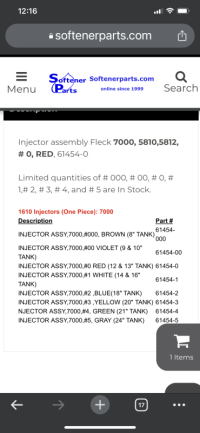

I did find some videos on how to service the Fleck 7000. While I watch all these videos, I found another question, what color of injector should I use? Does injector size matter? Looks like there is 3 different colors indicate different size of injector. I am just hoping to get all the parts needed and order them all in one time instead paying the unnecessary shipping separately.

There is reason I ask. I was never too happy with Fleck7000 since day one. I am sure it is a good unit, but unlike my old GE just plug and play for 11 years until I replacing it due to 3/4" piping. The house use 1 1/4" pipe but reduce to 3/4" due to the water softener connection size. I was hoping the new Fleck will not restrict the water flow as old GE.

Visit the forum and referred by forum member to purchase the Fleck 7000 from his company, install by the referral installer by same member. The installer is nice enough to pick up the softener from seller install the unit for me. When he open up the package, there is an additional Fleck 7000 valve unit besides the one is already on the tank. The installer thinks he is lucky to get a free valve unit....

By now you probably knew I know nothing about the softener unit. I am down $600 on resin replacement job+ order additional 1cf3 resin and other small parts already, I really want to make sure I get all the parts I needed in order to make this Fleck 7000 works as what it is design for. What else do I need to know? It is sad paying the money without getting the right service and product needed.

Thanks

I did find some videos on how to service the Fleck 7000. While I watch all these videos, I found another question, what color of injector should I use? Does injector size matter? Looks like there is 3 different colors indicate different size of injector. I am just hoping to get all the parts needed and order them all in one time instead paying the unnecessary shipping separately.

There is reason I ask. I was never too happy with Fleck7000 since day one. I am sure it is a good unit, but unlike my old GE just plug and play for 11 years until I replacing it due to 3/4" piping. The house use 1 1/4" pipe but reduce to 3/4" due to the water softener connection size. I was hoping the new Fleck will not restrict the water flow as old GE.

Visit the forum and referred by forum member to purchase the Fleck 7000 from his company, install by the referral installer by same member. The installer is nice enough to pick up the softener from seller install the unit for me. When he open up the package, there is an additional Fleck 7000 valve unit besides the one is already on the tank. The installer thinks he is lucky to get a free valve unit....

By now you probably knew I know nothing about the softener unit. I am down $600 on resin replacement job+ order additional 1cf3 resin and other small parts already, I really want to make sure I get all the parts I needed in order to make this Fleck 7000 works as what it is design for. What else do I need to know? It is sad paying the money without getting the right service and product needed.

Thanks

Attachments

Last edited:

These injectors are each acceptable, but some require a longer BD time

#00 Injector - Violet BD=130

#0 Injector - Red BD=60 to 70

#1 Injector - White BD=60

#2 Injector - Blue

I would prefer red or white. There is a good chance you have blue, which is acceptable. If not one of those, I would say not acceptable.

#00 Injector - Violet BD=130

#0 Injector - Red BD=60 to 70

#1 Injector - White BD=60

#2 Injector - Blue

I would prefer red or white. There is a good chance you have blue, which is acceptable. If not one of those, I would say not acceptable.

Silversaver

Member

The label indicate the injector is #0 red which is the proper size for 12" tank, but why a 2.4GPM DLFC for 12X52 tank?These injectors are each acceptable, but some require a longer BD time

#00 Injector - Violet BD=130

#0 Injector - Red BD=60 to 70

#1 Injector - White BD=60

#2 Injector - Blue

I would prefer red or white. There is a good chance you have blue, which is acceptable. If not one of those, I would say not acceptable.

I guess I'll have to wait unit the resin and other parts arrived, then open her up to find out. This is the part I don't understand. I pay for all the services and still cannot get it right... haha that suck big time

Error by seller.The label indicate the injector is #0 red which is the proper size for 12" tank, but why a 2.4GPM DLFC for 12X52 tank?

See https://terrylove.com/forums/index.php?attachments/599-7000-sizing-instructions-small-5-pdf.37633/

Silversaver

Member

Silversaver

Member

Opening her up. The resin level should be at 2/3 of tank correct? It is at about 60% now.

Update: Nothing I can do after taking her apart. The resin is at about 60% in the tank which is about right level since space is needed for resin expansion. I could not replace the leaking o ring due to the sweat connector: during the torch heat up when install, it melt the clip and it is bond to the copper sweat connector. When I try to remove the clip and it just break off. I am still able to reinsert the other 1/2 clip back on. I gotta figure out a way to get the clips off the bypass valve... the leak is very slow which I am good for now. All I can do it clean up and put her back together.

Thanks for the help

Update: Nothing I can do after taking her apart. The resin is at about 60% in the tank which is about right level since space is needed for resin expansion. I could not replace the leaking o ring due to the sweat connector: during the torch heat up when install, it melt the clip and it is bond to the copper sweat connector. When I try to remove the clip and it just break off. I am still able to reinsert the other 1/2 clip back on. I gotta figure out a way to get the clips off the bypass valve... the leak is very slow which I am good for now. All I can do it clean up and put her back together.

Thanks for the help

Attachments

Last edited:

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 1

- Views

- 638

- Replies

- 8

- Views

- 834

- Replies

- 2

- Views

- 598