Silversaver

Member

Hi guys,

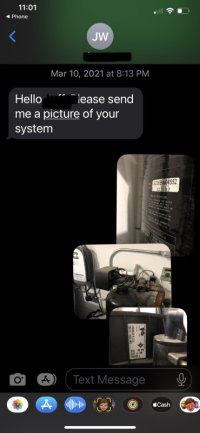

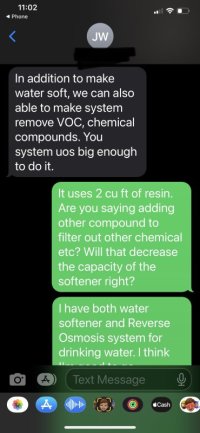

I am back since 2013. I have the Fleck 7000 64k unit installed with your help. In 2021, I ask the same guy install the system for me to help me replace the resin on this 64k unit. He did, but he only replace with one bag (1CuFt) of Purolite resin. I have always set the system with 48k at about 10lbs salt setting. Now, I am running out of soft water constantly.

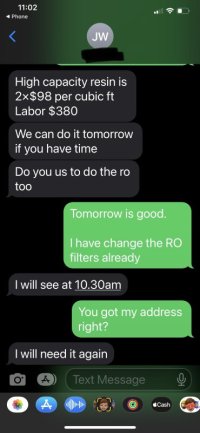

I did not know the 64k unit will need 2 CuFt of resin instead...... Long store short, what should I do now? Set the system with lower capacity or get an newer unit? It cost me $600 to replace the resin and I cannot afford to have another bad job. He should have know base on tank size it is a 64k unit that will need 2 bags of resin.

Thanks in advance.

I am back since 2013. I have the Fleck 7000 64k unit installed with your help. In 2021, I ask the same guy install the system for me to help me replace the resin on this 64k unit. He did, but he only replace with one bag (1CuFt) of Purolite resin. I have always set the system with 48k at about 10lbs salt setting. Now, I am running out of soft water constantly.

I did not know the 64k unit will need 2 CuFt of resin instead...... Long store short, what should I do now? Set the system with lower capacity or get an newer unit? It cost me $600 to replace the resin and I cannot afford to have another bad job. He should have know base on tank size it is a 64k unit that will need 2 bags of resin.

Thanks in advance.