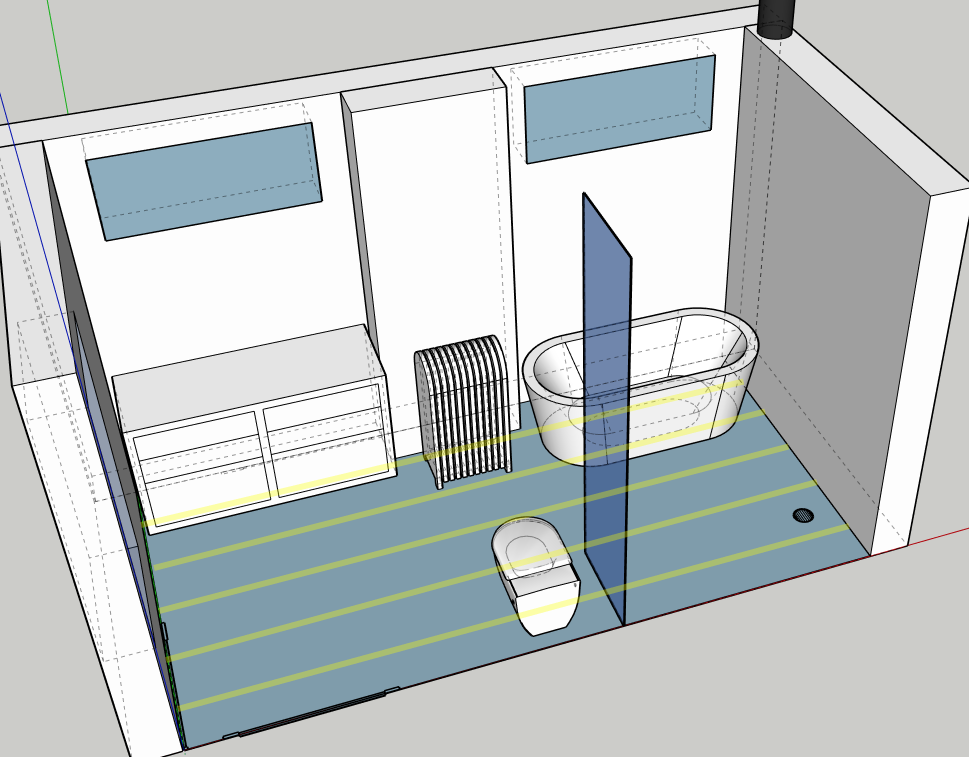

Remodeling a second-story master bath in a 1920's house that looks like it was redone in the late 90's — hopefully by an unwitting homeowner (and not a licensed plumber) because it was vented out the side wall, half behind the window shutter:

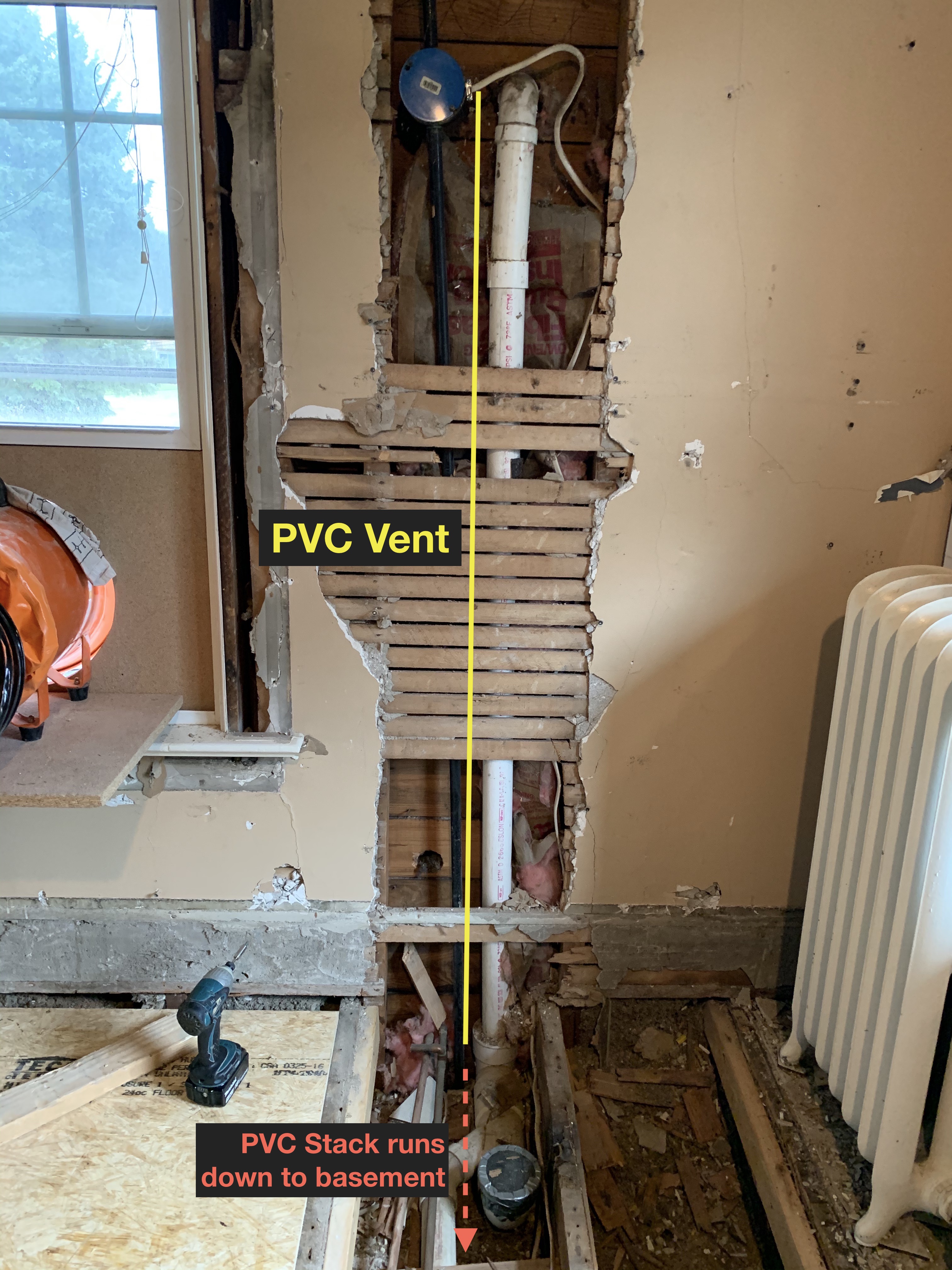

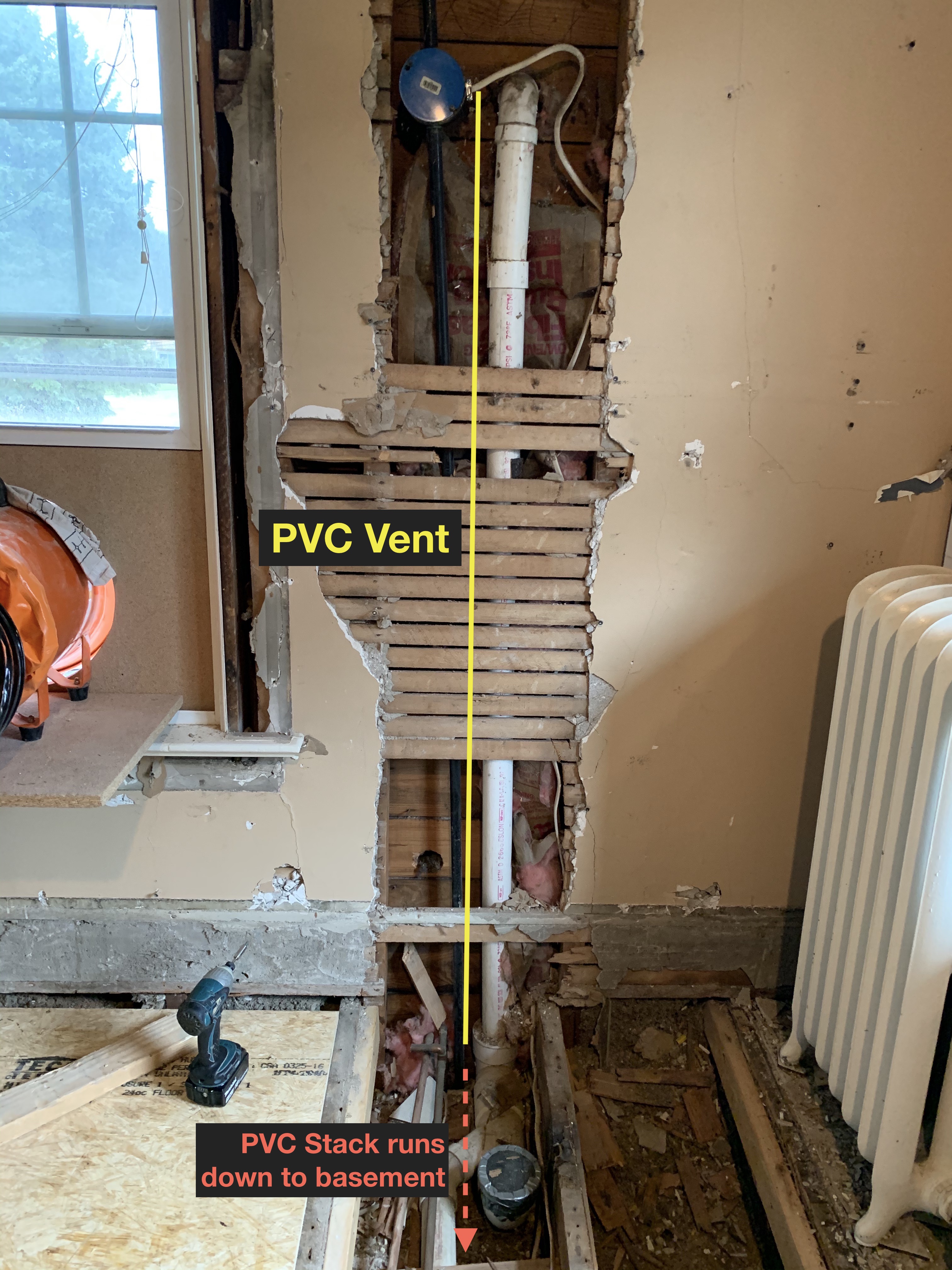

[edit: added for clarity] The PVC vent sits on top of a PVC drain stack that runs down the outside wall into the basement where it connects (rather poorly) into the main cast iron drain.

Inside

(also note the buried box)

Outside

Over in the opposite corner, the original cast-iron stack is still there, with the main bath on the other side of the wall currently tied in:

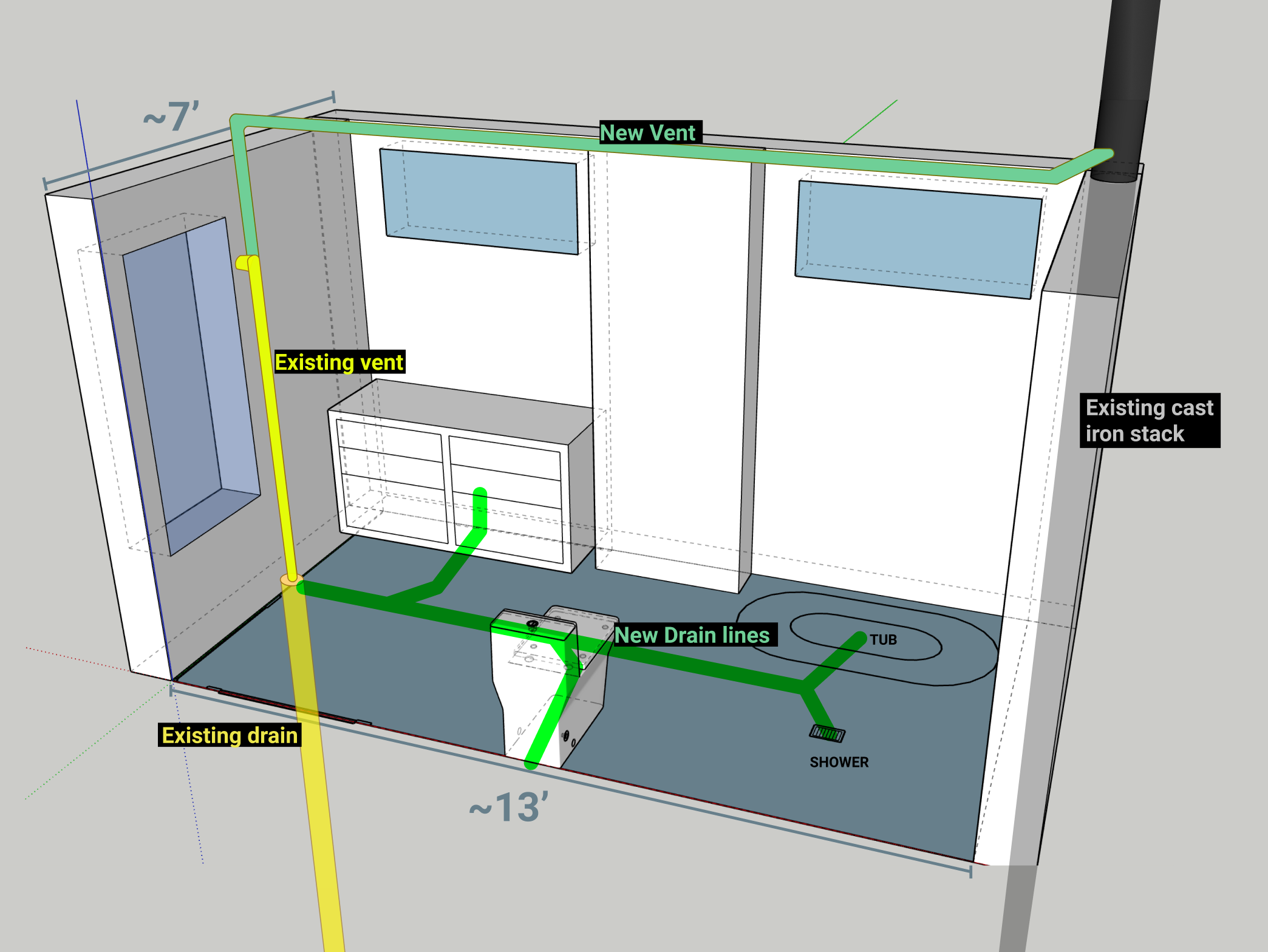

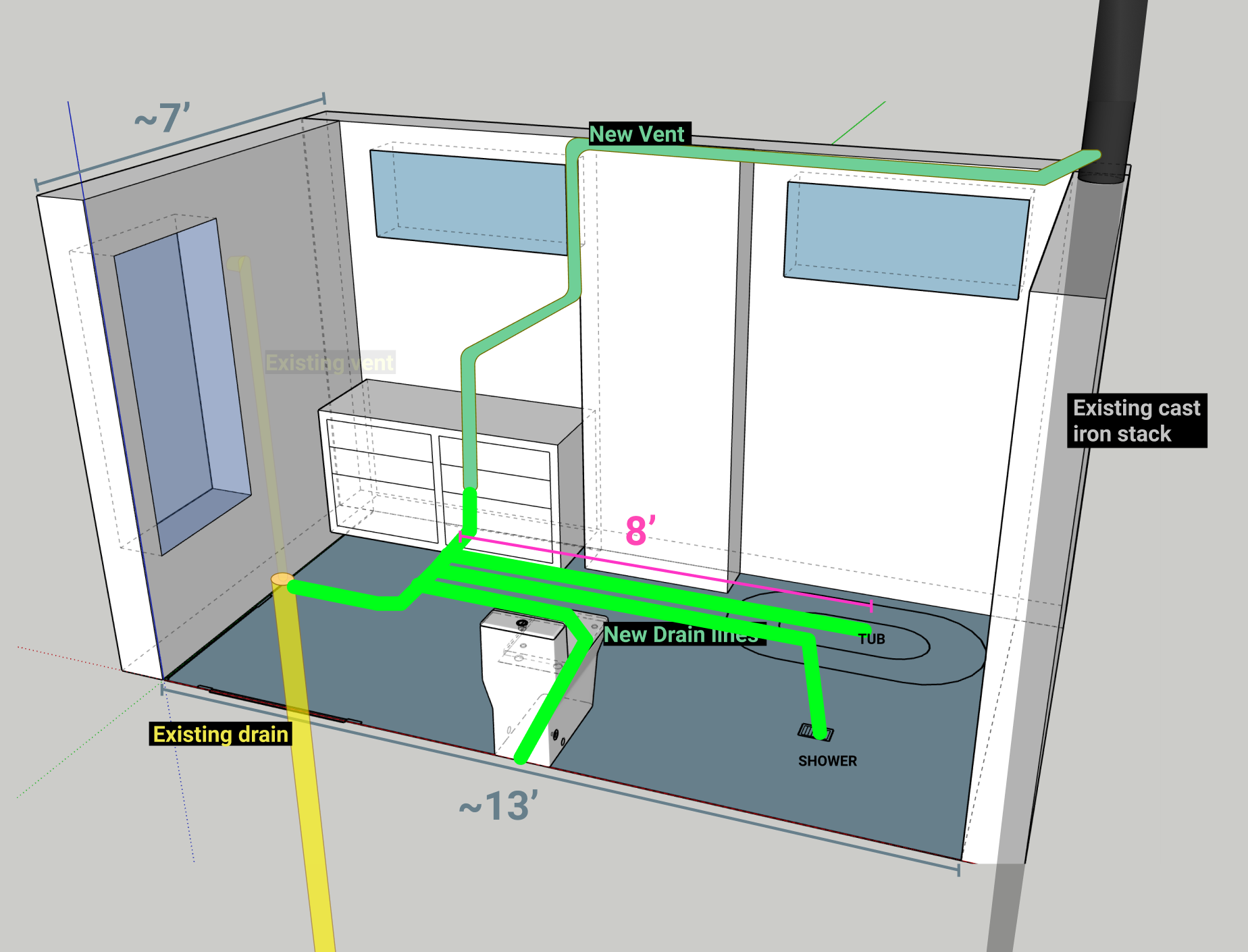

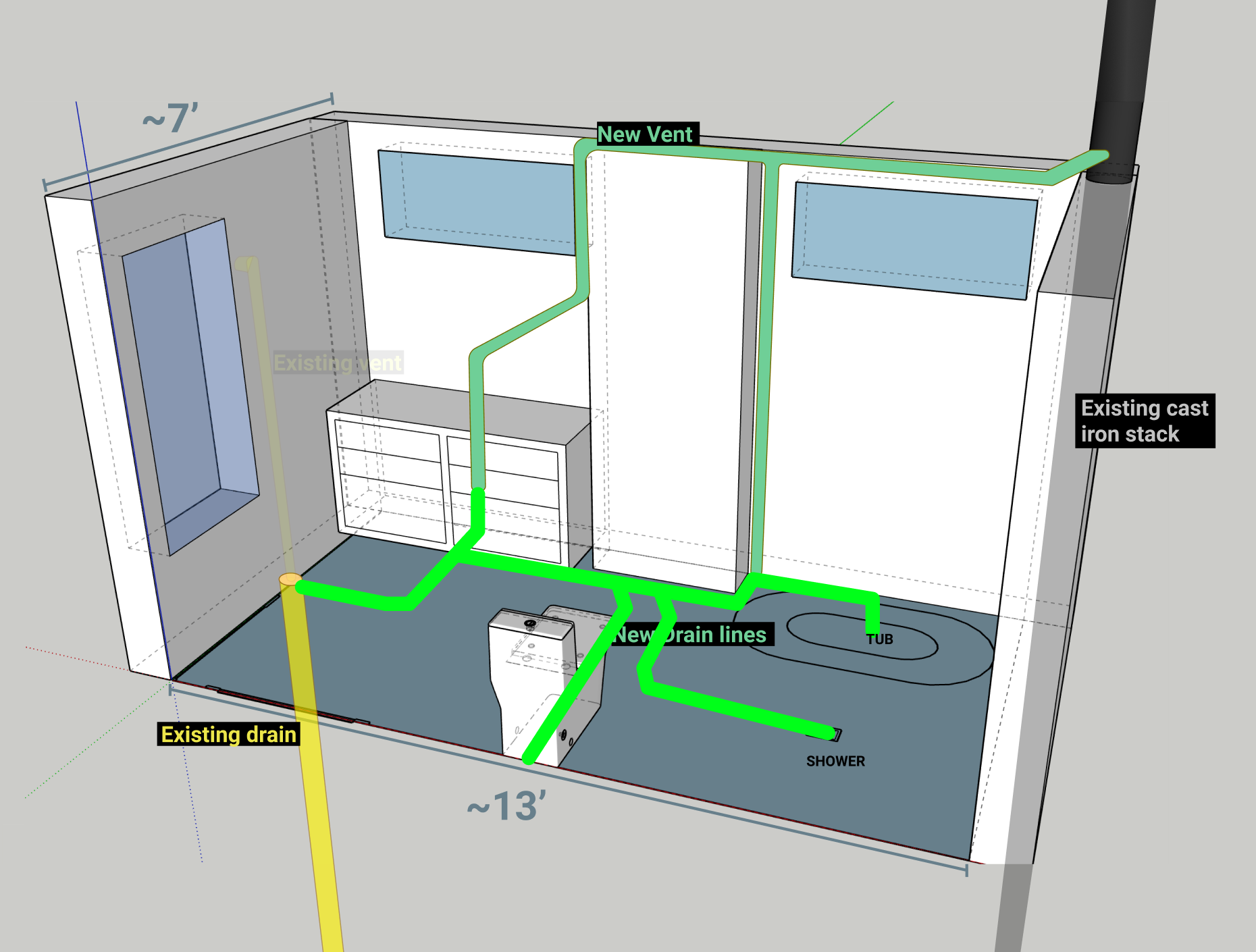

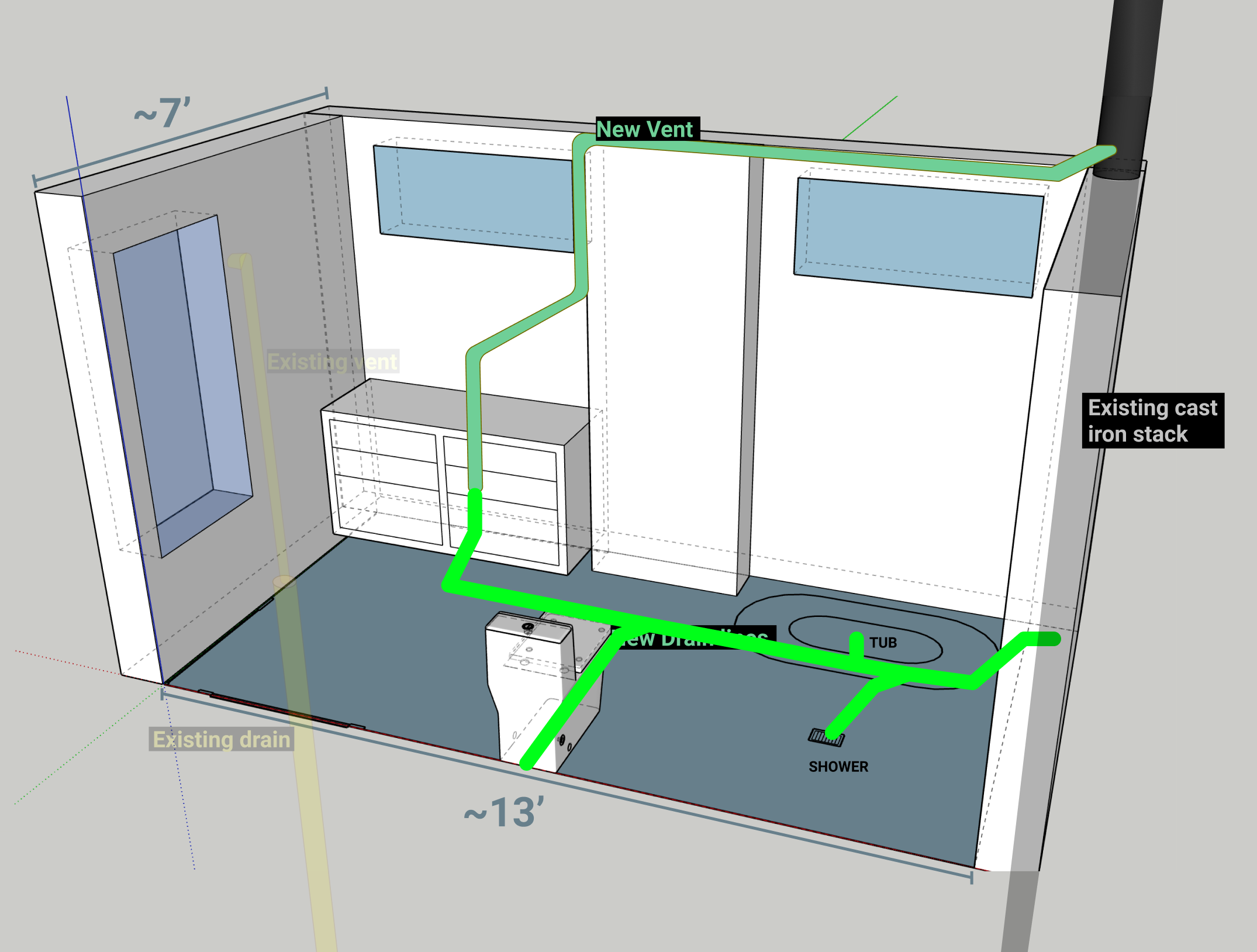

So it seems like I essentially have two options here.

1. Reroute the PVC that's currently going through the side wall, bring it up through the attic, and punch a hole in the roof with a new vent. Challenges here is that the attic is partially finished (original plaster/lathe), so I would have to be breaking through some walls to fish it through. The placement of the bathroom would make the vent end up either directly on the front pitch of the house (see picture below), or it would have go up and over — ending up within a few feet of the existing cast-iron vent. Also, it is what it is, but I'm not particularly excited about putting a new hole in the roof.

2. Tie into the existing cast-iron stack. Obvious challenges here are having to break into the cast iron, but make certain I can reconnect the currently operational tie-in with the main bath. The position of the flange/wye is a bit tricky since it's pretty well embedded in the joists/wall. Seems like one of those projects that could go sideways real quick.

I realize this is mostly a judgement call, but I wanted to hear from those who've had experiences with both of these options, and hear your thoughts on what would be the most sensible option (or, maybe even some better ideas)?

[edit: added for clarity] The PVC vent sits on top of a PVC drain stack that runs down the outside wall into the basement where it connects (rather poorly) into the main cast iron drain.

Inside

(also note the buried box)

Outside

Over in the opposite corner, the original cast-iron stack is still there, with the main bath on the other side of the wall currently tied in:

So it seems like I essentially have two options here.

1. Reroute the PVC that's currently going through the side wall, bring it up through the attic, and punch a hole in the roof with a new vent. Challenges here is that the attic is partially finished (original plaster/lathe), so I would have to be breaking through some walls to fish it through. The placement of the bathroom would make the vent end up either directly on the front pitch of the house (see picture below), or it would have go up and over — ending up within a few feet of the existing cast-iron vent. Also, it is what it is, but I'm not particularly excited about putting a new hole in the roof.

2. Tie into the existing cast-iron stack. Obvious challenges here are having to break into the cast iron, but make certain I can reconnect the currently operational tie-in with the main bath. The position of the flange/wye is a bit tricky since it's pretty well embedded in the joists/wall. Seems like one of those projects that could go sideways real quick.

I realize this is mostly a judgement call, but I wanted to hear from those who've had experiences with both of these options, and hear your thoughts on what would be the most sensible option (or, maybe even some better ideas)?

Last edited: