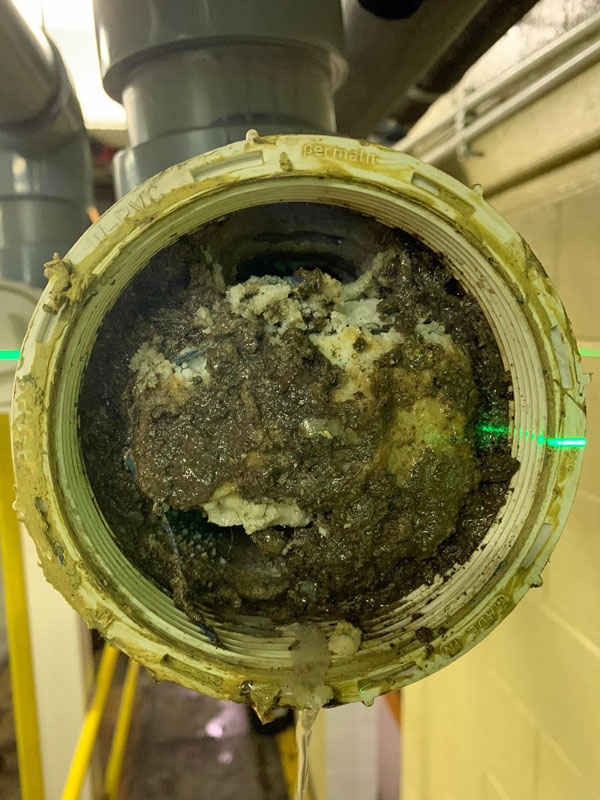

Bath remodel is slowly moving along. Appreciate the previous help immensly. I'm going to replace the sub floor, and would like to move the toilet flange about an inch or two over anyway (offset flange), but I'm wondering what the best way to do that might be? It's all copper (and brass?), and two of the screws are rusted so bad that I'm not sure they'll come out. I think I will need a new toilet flange either way. The clearance between the sub floor and the bottom of the joists on either side of the pipe is about as tight as it can be (3 1/2"). I'll have to notch the joist to accomodate the offset flange (and even for the hub on the flange connection).

Should I cut the 3" copper on the vertical below the joists, run 3" PVC up to the new flange, and connect it with a fernco banded coupler? Or cut it on the horizontal part, and add a long sweep PVC 90? Or would something else be better?

I'm leaning towards cutting it on the vertical, as it seems like that would be better to minimize the clog potential, but I'm not excited about having a transition of any sort for this reason. Re-using the existing flange might be possible (though the placement isn't ideal) if I'm just asking for trouble introduing a transition anywhere so close to the toilet.

What would you do if it were your bathroom?

Should I cut the 3" copper on the vertical below the joists, run 3" PVC up to the new flange, and connect it with a fernco banded coupler? Or cut it on the horizontal part, and add a long sweep PVC 90? Or would something else be better?

I'm leaning towards cutting it on the vertical, as it seems like that would be better to minimize the clog potential, but I'm not excited about having a transition of any sort for this reason. Re-using the existing flange might be possible (though the placement isn't ideal) if I'm just asking for trouble introduing a transition anywhere so close to the toilet.

What would you do if it were your bathroom?