The 3" of closed cell is a waste of money. You'll be MUCH better off with 4" of open cell, despite being only ~R15 at center cavity. The reason for this is that the framing fraction on full-dimension lumber framing is over 25% of the wall surface area, and with the 3" thick thermal bridge of the framing fraction is only ~R3.5, and that 25% framing fraction is conducting more heat than the R21 foam. If you go for a full cavity fill of half-pound open cell the framing fraction rises to about R5, and the net "whole-wall R" is slightly higher.

If you count up the insulating value of the sheathing, siding, wall board and gypsum board and account for the thermal bridging of the framing, even at 25% (which would be typical for milled lumber) the R7/inch 3" solution comes in at about R11.35 "whole wall, and the 4" of R3.7/inch open cell foam comes in at R11.6.

At a more likely 28% framing fraction the 3" closed cell solution comes in at about R10.8, compared to R11.2 for the 4" open cell solution.

In the unlikely event that the house had a 20% framing fraction (balloon framed, single top plates & headers, few jack studs, etc. ) the 3"c.c. edges out the 4" o.c. solution at R12.5 to R12.3. That's the most expensive R0.2 you can buy.

The closed cell solution is a class-II vapor retarder, and offers protection for the sheathing from interior moisture drives whereas the open cell does not, but it also offers very little drying rate toward the interior. For about 15 cents per square foot you can install 2-mil nylon (Certainteed MemBrain) on the interior side of the open cell foam. During the winter when the air is dry the nylon is a Class-II vapor retarder, and protetive of interior moisture drives. But when the sun starts cooking accumulated dew or wintertime moisture out of the sheathing the sheet nylon becomes more vapor open, and allows some of that moisture to dry toward the interior. Odds are pretty good that the antique clapboards have coats of oil base (or even leaded) paint, which is very vapor retardent, so the drying a capacity toward the exterior is limited. If you insulate with closed cell foam the moisture content of the siding will be higher, and paint failure more frequent than with an open cell + sheet nylon solution.

Closed cell foam runs about $1/board foot, so you're looking at $3/square foot for the R21 foam. Open cell foam runs about 35 cents per board foot, so 4" of foam would run about $1.40 per square foot, plus the cost of the 2 mil nylon comes in at about $1.50/square foot, it's literally half the cost for similar or higher thermal performance and delivers greater moisture resilience.

Also, the environmental impact of open cell foam is also just a fraction that of closed cell. The full 4" has the same amount of polymer as 1" of closed cell, and open cell foam is blown with water, whereas nearly all R7/inch closed cell foam is blown with HFC245fa, a powerful greenhouse gas (~1000x CO2 @ 100 years.) Putting closed cell foam between studs is an utter waste- it's much better put to use where it's moisture characteristics actually buy you something:

The band joists can be insulated with either 1" of closed cell + R23 rock wool batts, or 5.5" of open cell. The foundation below grade would meet code-min with 2" of closed cell, or 1" of closed cell plus a 2x4/R13 studwall (no vapor retarders desired or necessary, but kraft facers are OK) if you opt to finish it out. An uninsulated unsealed quarried granite foundation is a huge air & heat leak. If left untreated it would probably account for the majority of your air infiltration, and more than 25% of your total heat load (even if you insulated between the joists), and the summertime infiltration will contribute a huge latent cooling load to the house (== musty basement smell.) Sealed and insulated with some amount of closed cell foam (even if it's in combination with fiber) the heat loads and moisture load will drop by 90%, the basement will be both more comfortable and smell lot better (or need a lot less mechanical dehumidification.)

If the roof vented, what is the venting scheme- soffit to ridge, gable vents, or ??? Is this house going to be re-roofed?

In a vented attic air sealing the attic floor and going with blown cellulose is superior to fiberglass. Air sealing attic floor the chimney chases requires metal air-barriers mortared &/or caulked with fire-rated caulk. You can then wrap the chimney with R15 rock wool batts secured with steel wire to keep it from falling off, after which it's safe to use blown cellulose.

The exterior chimney can be insulated on the exterior if it's otherwise going to be a gaping hole in your thermal envelope. Making the wood-stove flue penetrations fully air tight can be difficult, but it's possible to signficantly reduce what would be an significant air leak. Blocking the parasitic air leaks of the granite fireplace can be more difficult, but if it's a terra cotta lined flue in reasonable shape, gasketed top sealing dampers are superior to any steel flap damper that might have been original equipment.

If using a boiler instead of a water heater, the amount of radiation on each zone has to be reasonable for the boiler output to keep it from short cycling, and since the boiler will of-necessity be oversized for the whole house load. To fully balance heat emitted from the radiation with the ~74,000 BTU/hr output of something like the smallest

Burnham MPO-IQ, would take about 120 feet of

typical fin-tube baseboard, even running it at 190F-200F output. If any one zone has less than half that the short-cycling during single zone calls will be pretty severe, even with heat purging smart controls. The 61K output of the smallest 3-plate

Biasi B10 would still need at least 100' to balance. But with a likely heat load of something like 35-40,000 BTU/hr it would only take 80' of baseboard to fully heat the place, with margin to spare, and it would be broken up into zones each of which would be a in short-cycling territory.

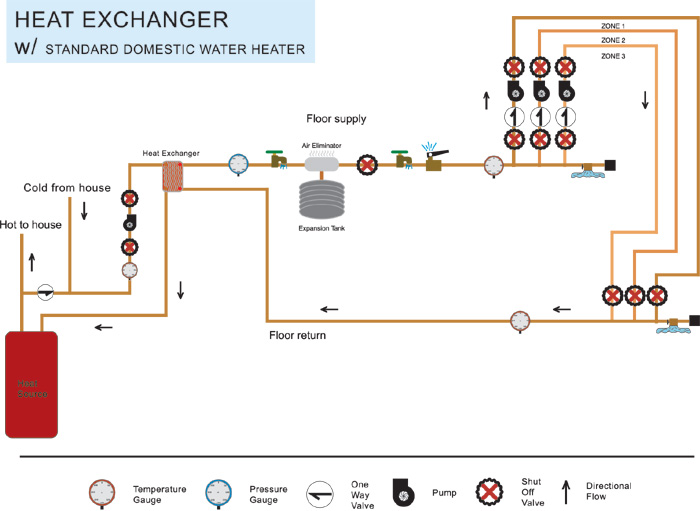

If instead of a boiler you used a hot water heater and designed the radiation for 140F average water temp it would take about 125' of baseboard total (on the order of 2x that of a high-temp solution), but the thing won't short cycle due to the buffering thermal mass of the water in the tank. Something like a

30 gallon or bigger Bock , or any

Everhot TFI would have enough burner output to cover your design heat load AND a simultaneous 2.5 gpm shower all day/night long on the coldest day of the winter.