The min-fire input on the CH210ASME is 20,000 BTU/hr, ao at 95% efficiency it would be delivering 19,000 BTU/hr, which is approximately your 99% design heat load (70F inside, 10F outside, 60F difference). That means that even without low temperature water it is guaranteed to be cycling rather than modulating with the heat load.

With 54' of

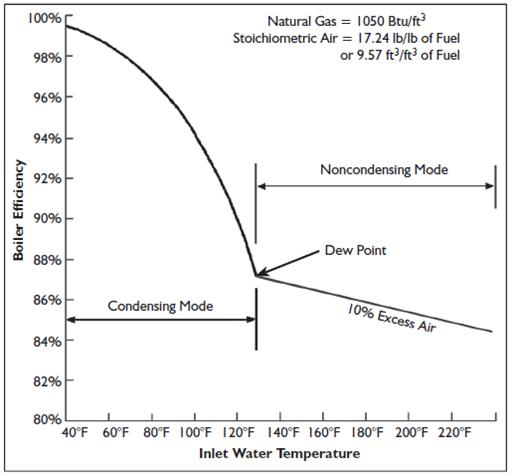

SlantFin that would be ~350BTU/hr per foot of baseboard, which would balance perfectly at an average water temperature (AWT) of about 145F without forcing it into a cycling mode. With an out to in temperature difference (delta-T) of 20F the entering water temperature (EWT) would be about 135F, which is above the condensing zone, but not far above the condensing zone. So it's probably running about 86-87% efficiency at the 99% outside design temp if you hold the line at 150-155F.

At an AWT of 130F it would be in the condensing zone, and the baseboard would be delivering 14-15,000 BTU/hr, which is MOST of the output, with ~5000 BTU/hr of "excess" forcing the temperature rise & cycling. The question is only how MUCH cycling.

Without the wired remote, this boiler can be set up to control either the supply temperature OR the return temperature, using the DIP switches on the control board. See p51 of

the manual. The remote would overide any of the DIP switch settings, but it's possible, or even likely that it is currently set up for return temperature, rather than output temperature control.

If the boiler was installed with Navien's hydraulic separator manifold or similar, the delta-T at the boiler will be smaller possibly as low as 5F. On a milder day, set the boiler to 125F (in or out) and observe the behavior- time the burns, and count the burns per hour. The temperature overshoot before the it turns the flame off, and the temperature undershoot at which it re-fires are programmable on some boilers, but I couldn't find indications that those parameters are adjustable on this one. Do you have the remote, and the manual for the remote? But let's assume it's 10F between flame-out & re-fire.

With 54' of 3/4" tube and you have about 8 lbs of water in the fin-tube and 27lbs of water in the PEX, or 35lbs total. With 6000 BTU/hr (100 BTU/minute) of excess heat going into the system the temperature is slewing about 3F per minute, and for a 10F swing around the set point you'd get a ~3 minute burn. At 12,000 BTU/hr out (what the 54' of fin-tube emits at an AWT of 125F) it would take about 6 minutes to re-fire, for 9-10 minute cycles, and 6-7 cycles per hour, which would be fine. you'd be in the low 90s for combustion efficiency for most of the heating season, probably 90% AFUE, a 4-5% savings.

With outdoor reset you don't get a lot of programming options with this boiler, but set up to control the return temp using the K-factor curve somewhere between 2.5 and 3.5 would probably do the right thing given your estimated heat load, radiation, and water volume.