Ridge venting without soffit venting of equal or larger free area doesn't do much. Does it already have soffit vents?

IRC code minimum is R49, not R38.

To hit R38 with the code-mandated 1" vent gap for a vented roof would take a total depth of 11.25" even using high density fiberglass, which is 4" of headroom gone from your room (and a lot of work). To hit R38 with low-density batts takes 12.5" of depth, stealing 6.5" of headroom on the sloped ceilings.

HFO-blown closed cell polyurethane foams run about R7/inch. With a 2x8 rafter you have 7.25" of space, which is enough to hit ~R49 unvented without adding any depth to the rafter bays. It's moisture safe for the roof deck, but it's expensive (about $1.25-$1.50 per square foot per inch of depth in my area- that's $9-10 per square foot for R49.) If you stopped at 5.5" it would hit your sub-code R38 goal, but it would still be pretty expensive.

In zone 6 to go

unvented you need at least half the total R to be air-impermeable insulation. With just 3" of HFO blown foam ($4-5 per square foot) you'd be at about R20-R21, and would have 4.25" left over in a 2x8 rafter bay for fiber insulation, which is enough to hit your goal in a moisture safe manner:

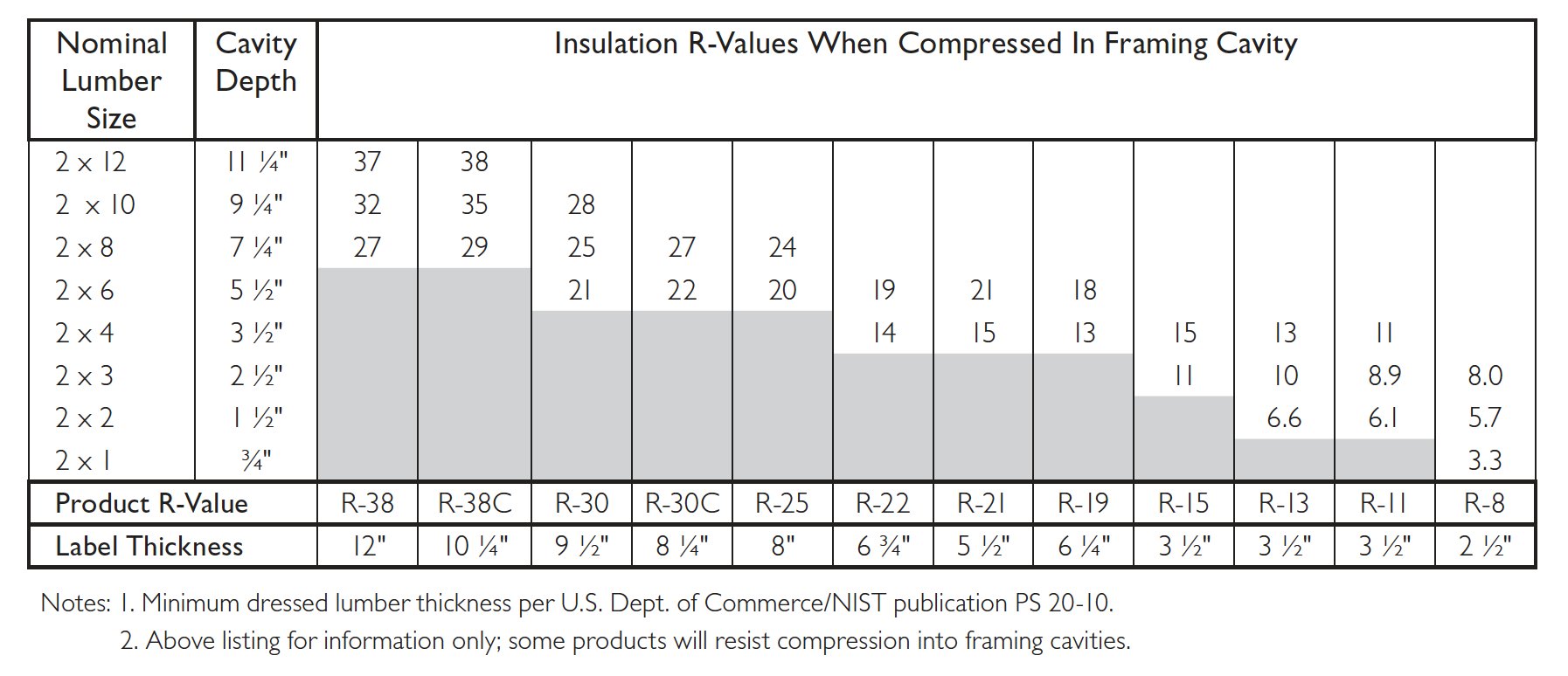

A high density "cathedral ceiling" fiberglass batt designed for 2x6 would perform at about R18 when compressed to 4.25" and you'd hit your R38 goal without extending the rafters.

An R23 rock wool batt designed for 2x6 cavities would perform at about R19 when compressed to 4.25", for modestly better thermal performance (but far better fire resistance, and low/no risk of airborne fiber particles reaching your indoor air.)

With either rock wool or HD fiberglass and 3" of HFO-blown closed cell foam you'd still have more than half the total R exterior to the foam/fiber interface, so no interior side vapor retarder (other than standard latex ceiling paint) would be necessary to avoid moisture accumulation in the fiber over the winter.

It's easier to get the necessary air tightness if you move ALL of the insulation up to the roof deck when going with a cathedralized ceiling in an attic room, whether vented or unvented. This adds quite a bit to the expense. To do it with insulation on the floor of your mini side-attics behind the kneewalls requires making meticulous air dams in each floor joist where it crosses under the kneewall, on each end. Otherwise the ventilation air in one mini-attic can and will cross under the floor to the other mini-attic whenever the wind blows, taking heat out of the room's floor when it does. Simply stuffing it full of low-density cellulose isn't good enough as an air barrier.

The kneewalls themselves would also need 1.5"- 2" of fire-rated foil faced polyiso on the attic side of the kneewall to meet current IRC code minimum performance. It would need at least R7.5 just for moisture control in the kneewall assembly, but that would be R2.5 shy of the thermal performance called out in the code.

When it's all said and done, given the large PITA factor for sealing up the mini-attics behind the kneewalls it's better and often cheaper to do it all at the roof assembly.

It's your call as to whether extending the rafters to do a vented assembly with fiberglass R38 is really worth it. If you went with an unvented foam/fiber hybrid in 2x8 rafter bays, when it comes time to re-roof adding 1.5" of reclaimed roofing polyiso (or a 2" polyiso nailbase panel) above the structural roof deck would meet or beat current IRC minimum performance.

A primer on the topic of insulating at the roof assembly lives here, hitting most of the main points and options. Note that in the blog piece they point out the IRC prescriptive minimum of R25 for the foam in a hybrid approach in climate zone 6. That's true-

it's written in the code that way, but the presumption behind that prescriptive is a total of

R49, the code minimum. The key determinant of condensation risk is the ratio. R25/R49= 51%. For an R38 assembly you'd only have to meet or beat 0.51 x R38= R19 for the foam layer to have the same ratio.

With 3" of HFO blown foam you're there, but not with 3" of cheaper (but more environmentally damaging) HFC blown closed cell foam, so you'd have to go to 4", (at about the same cost as 3" of HFO blown) and it would have to be installed in two 2" lift with a cooling off period between them, whereas HFO blown foam can be installed at 3-4" in a single pass without quality problems or fire risk during curing.