Thank you Dana. I wish the builder of this house 26 years ago put that kind of though into the duct work design. From what I can tell there are no type of deflectors inside the rectangle return trunk or anywhere for that matter. So if the 26” extension beyond the drop to the air handler on the left in the picture of my duct was intentional to slow the turbulence, would it affect air flow or noise if I cut it back flush with the new wall I built? Just thought they may have run it longer to give some flexibility as to where they placed the air handler.

It's hard to ascribe any intentions to the original installer. Could be sheer laziness, lack of a specified duct plan, but it probably was

not to reduce turbulence.

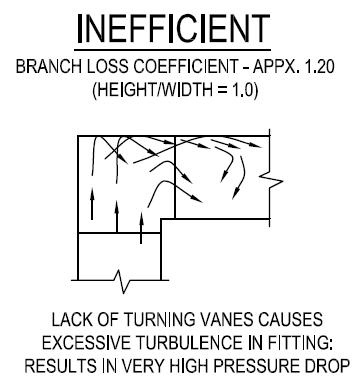

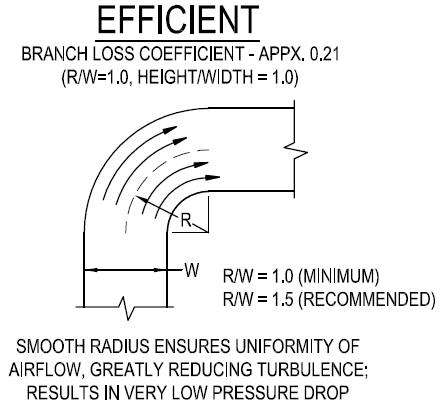

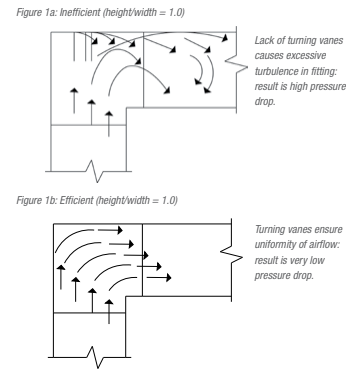

As long as cutting it flush to the studwall doesn't create a reduction from the main return duct to that point it's fine. Even a small radius (or even a short 45) on the throat (inside of the turn) of the new-improved duct will reduce turbulence & noise. A radiused outside of the turn also helps, but it isn't as important as the inside radius of the turn.

Be sure to mastic-seal all joints & seams of the new ductwork, and any other ducts you have easy access to. Duct mastic is messy, but it's cheap and more reliable than tape. Apply generously, obliterating evidence of seams or screws in the ductwork (typically 1/4" will do).

The mastic application on the picture below is a bit to thin- it might seal, but it may also miss and leak a bit in a few tiny hard to inspect locations:

Even pinhole leaks can create an annoying hiss, even when the total leakage isn't big enough to be consequential for efficiency.

If using tape to seal joints & seams, use a temperature rated HVAC tape (eg: Nashua 324A is commonly found at box stores), and wipe down the surface with a mild solvent such as isopropanol (rubbing alcohol) to remove any oily residues that will affect long term bonding of the adhesive before applying the tape.