With insulation in the basement and R40 in the attic and U0.34 windows I'd be surprised if the true load was over 38,000 BTU/hr. My "after" picture estimat was:

"...

headed for 30,000-35,000 BTU/hr after upgrades."

His Manual-J came out ~50% higher than that, which isn't very close at all in my book. It's hard to know where the next 15,000 BTU/hr came from. Seriously, I've seen many ~2500' houses with uninsulated basements that came in under 50K @ 0F, and none that were over 40K after air sealing & foundation insulation.

What was he using for an outside design temperature?

What did he insert for a ventilation/infiltration load number?

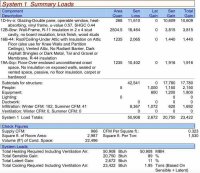

A totally dumb I=B=R WAG on a 2-story ~2500' house with 3' of above-grade R10 foam insulated basement, and 350 square feet of U0.34 window, 45 square feet of 2" solid door, assuming a rectangular footprint of 31 x 40', an indoor design temp of 70F, outdoor design -5F (75F delta-T) and R40 in the attic:

Attic U-factor ~0.035. Attic floor area 1240'. Attic losses are:

U0.035 x 1240' x 75F= 3255 BTU/hr

Wall U-factor ~0.08 (including the above grade basement wall). Assuming 11' per story + 3' of above grade basement the gross wall area is perimeter x 25' of height, less windows and doors. The perimeter is (31+40)x 2= 142', so the gross area is 25 x 142= 3550'. Less 350' of window leaves 3200', less 45' of door leaves 3155' of wall. Wall losses are:

U0.08 x 3155' x 75F= 18,930 BTU/hr

Window losses:

U0.34 x 350' x 75F= 8925 BTU/hr

A 2" wood door has a U-factor of about U0.50. Door losses are then:

U0.50 x 45' x 75F= 1688 BTU/hr.

Add it all up and you're at 32,798 BTU/hr.

Throw in another ~5K for below grade & slab losses plus air infiltration and you're still only at 38K. From there you start subtracting for the warm bodies and plug loads (250 BTU/hr per sleeping human, another 300-350 BTU/hr for the refrigerator, 200-300 BTU/hr for the TIVO, etc.)

If you assume the place is a leaky sloppy 20ACH/50 wind tunnel for air tightness (not likely if it feels snug and not drafty) you might hit 50K, but I'm not quite buying his numbers, unless my crayon-on-napkin model of your house is dramatically different from your actual house. Before basement insulation it's probably over 40K, but not by much.

A U-factor list selected at random from the web for sanity checking my number lives here.

Regarding boiler output, and alternatives...

The

DOE output of the Solo 60 is 54,000 BTU/hr, not 47K, which is the IBR output number. If you are installing the boiler out in the garage, on the other side of the insulation you'd use the IBR number, but if it's going in the basement, the distribution and jacket losses accrue to the heat load of the house, and are not lost, thus the DOE number is the right one to use. So even if his 51K number is right (not likely), if the boiler is in the basement you're still covered.

The smallest

Lochinvar Knight has comparable output numbers with smaller steps in the series than the Solo, but I'd still be recommending the WHN055 over the WHN085 for your house, since your likely average winter load is maybe only ~50% more than the min-fire output of the -085. The -055's output is about 10.5K @ min fire, which means it can still modulate well into the shoulder seasons.

The

Burnham ALP080 is another option, with a high-fire a bit bigger than the Solo-60, but with the same min-fire (though still higher than the WHN055, and not much lower than the WHN085).

Way out in left field, but still worth thinking about, the

HTP Versa Flame or Versa Hydro combi heat/hot-water systems work well, and are inherently self-buffered by the thermal mass of the hot water tank, making the comparatively high min-modulation range less important. The fact that the max output is more than 2x your calculated heat load (and ~3x your likely actual heat load) gives you less to worry about, and it takes up barely more space than a 50 gallon standalone HW heater.