The Scene (Problem Statement):

I recently bought and renovated a 1983 house with a well, and it is the first time I’ve owned a well. The renovations included a spa shower (Moen ioDigital) with four loops: two showerheads and two sets of dual bodysprays. The water volume/pressure is adequate at best, but after a few minutes the pressure drops substantially, which causes two problems: One is that it renders us unable to fully use all the water sprays; and Two is that the pressure drop “confuses” the valve controller and causes it to wildly cycle between hot and cold, which is a bigger issue!

I’ve hired several plumbers, several well drilling companies, and even a water softener company, and either they want to sell me a product without being able to explain if or how it will solve the problem, or they simply shrug and suggest I call one of the other trades…

Here are the details:

The Props:

The Actors:

The Happy Ending to the Story:

??

Everyone wants to sell me something but nobody can really demonstrate that they understand the nature of the problem and why what they sell me will resolve it. I don’t have $10,000 to spend on a shotgun menu of things that may or may not fix the problem, but until I understand exactly what the cause of the problem is, I can’t make a smart investment in solving it.

I’m hoping desperately that one of you guys can help.

I recently bought and renovated a 1983 house with a well, and it is the first time I’ve owned a well. The renovations included a spa shower (Moen ioDigital) with four loops: two showerheads and two sets of dual bodysprays. The water volume/pressure is adequate at best, but after a few minutes the pressure drops substantially, which causes two problems: One is that it renders us unable to fully use all the water sprays; and Two is that the pressure drop “confuses” the valve controller and causes it to wildly cycle between hot and cold, which is a bigger issue!

I’ve hired several plumbers, several well drilling companies, and even a water softener company, and either they want to sell me a product without being able to explain if or how it will solve the problem, or they simply shrug and suggest I call one of the other trades…

Here are the details:

The Props:

Well Pump: age, brand and specs unknown. Controller reads STA-RITE, ½ HP, 3450 RPM, Model IP4C02. Comes into the house on a 3/4” line and goes to the pressure tank. Straight from the pump inlet, the pressure is about 22 gpm at 50 psi, and 13-15 gpm at 30 psi (per the water softener guy).

Pressure Tank: AMTROL 32 gallon tank, a couple years old. Pressure switch 40/60 psi.

Water Softener: Sear Kenmore 625.3484500, rated at 8 gpm service flow, circa 1987? Plumbed with 3/4” hard copper from the pressure tank, but goes through 9 elbows and 2 flex lines in the span of the ~15’ it takes to get to it. Output splits off a few places to feed the rest of the house, then feeds into the HWH.

HWH: GE SG60T12YVK00 50gal nat gas “high-recovery”, brand new. Cold supply tees in just above the inlet and feeds the upstairs bathroom via 3/4" PEX straight up about 20-25’ of head. Hot output from the HWH does the same.

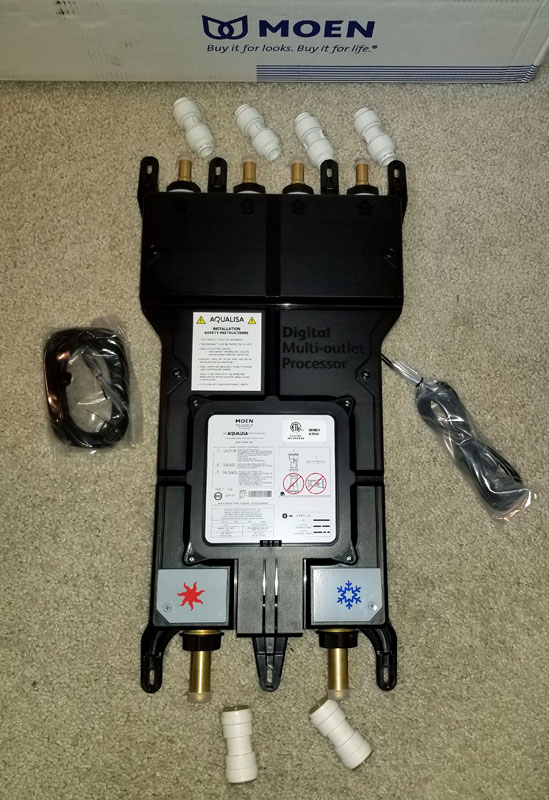

Spa Shower: Moen ioDigital 3/4” valve with max flow rate of 17.5 gpm @ 45psi. Four loops: Two shower heads, and two loops with two body sprays each.

Other fixtures in the house: powder room (toilet and sink), bathroom (std shower, toilet, sink), kitchen sink, two outdoor spigots, future bathroom (shower, toilet, sink)

Only two adults in the house.

Pressure Tank: AMTROL 32 gallon tank, a couple years old. Pressure switch 40/60 psi.

Water Softener: Sear Kenmore 625.3484500, rated at 8 gpm service flow, circa 1987? Plumbed with 3/4” hard copper from the pressure tank, but goes through 9 elbows and 2 flex lines in the span of the ~15’ it takes to get to it. Output splits off a few places to feed the rest of the house, then feeds into the HWH.

HWH: GE SG60T12YVK00 50gal nat gas “high-recovery”, brand new. Cold supply tees in just above the inlet and feeds the upstairs bathroom via 3/4" PEX straight up about 20-25’ of head. Hot output from the HWH does the same.

Spa Shower: Moen ioDigital 3/4” valve with max flow rate of 17.5 gpm @ 45psi. Four loops: Two shower heads, and two loops with two body sprays each.

Other fixtures in the house: powder room (toilet and sink), bathroom (std shower, toilet, sink), kitchen sink, two outdoor spigots, future bathroom (shower, toilet, sink)

Only two adults in the house.

The Actors:

The plumber says a second hot water heater will improve the water stability feeding the valve controller because it will double the amount of hot water available, and also act as a secondary storage/pressure tank.

The plumber also says that the cold water supply line for the bathroom should NOT be tapped near the HWH because it will “siphon” the cold supply from being able to flow into the HWH. This sorta makes sense, though I don’t understand how tapping the cold supply line in ten feet away will really change that.

The plumber also suggested a larger pressure tank and “tweaking” the cutover settings (which are already set to 65 psi). When I probed him on how he sized the tank requirement, he punted and said call a well company… which I then did.

The well driller says that I need a variable speed pump. I asked him about cycle-stop-valves and he said, nah, I’d need a pump that can keep up. He said the water softener looks like a problem too, and suggested I call a water softener company… which I did.

The water softener guy says the softener is likely constructing flow because it is ancient old, and because the supply line feeding it has 9 elbows in it, plus 2 flex lines. He suggests running a 1” line right from the well pressure tank into a new water softener (without all the elbows), and then installing a manifold block and re-running all the plumbing lines in a home-run from this manifold.

The plumber also says that the cold water supply line for the bathroom should NOT be tapped near the HWH because it will “siphon” the cold supply from being able to flow into the HWH. This sorta makes sense, though I don’t understand how tapping the cold supply line in ten feet away will really change that.

The plumber also suggested a larger pressure tank and “tweaking” the cutover settings (which are already set to 65 psi). When I probed him on how he sized the tank requirement, he punted and said call a well company… which I then did.

The well driller says that I need a variable speed pump. I asked him about cycle-stop-valves and he said, nah, I’d need a pump that can keep up. He said the water softener looks like a problem too, and suggested I call a water softener company… which I did.

The water softener guy says the softener is likely constructing flow because it is ancient old, and because the supply line feeding it has 9 elbows in it, plus 2 flex lines. He suggests running a 1” line right from the well pressure tank into a new water softener (without all the elbows), and then installing a manifold block and re-running all the plumbing lines in a home-run from this manifold.

The Happy Ending to the Story:

??

Everyone wants to sell me something but nobody can really demonstrate that they understand the nature of the problem and why what they sell me will resolve it. I don’t have $10,000 to spend on a shotgun menu of things that may or may not fix the problem, but until I understand exactly what the cause of the problem is, I can’t make a smart investment in solving it.

I’m hoping desperately that one of you guys can help.