RandyVMD

New Member

I recently purchased a deep well submersible deep well pump from an ebay vendor with the primary intention of using this pump for irrigation from a spring basin to a large pond in my front yard. Pump came with 100 feet of stranded 4 wire cord attached and a control box. electrical cord attached to control box was a 2 prong European plug with an adapter provided for standard north American 110volt outlets (Chineese product). Hooked this up according to specks and needed an extension to supply power from my shed which is serviced by direct bury outdoor 12/2 grounded wire to a 200amp subpanel in my garage roughly 100 feet away. selected a convenient cord of 50 feet that may have only been 16ga.

powered up the pump and was very impressed with the water flow, obtained a full 1 1/2" pipe of water at the top of a 25 foot rise and let this flow into a downspout collection basin that feeds to the pond.

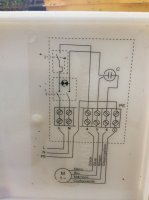

First issue was that the European plug adapter immediately became hot and shorted out so I opened up the control box and replaced the pigtail plug with a standard US plug that I scavenged from a scrapped microwave, seemed to be equivalent guage. Set pump back in operation and it provided good flow for about 6 hours then the 20 amp breaker started tripping and shutting down the pump. Assuming my extension cord may be an issue, I replaced it with a 12 gauge cord and operated the pump again only to find that the control box wire leading to the circuit breaker continues to heat up within minutes of use and trips the breaker.

Not sure what to do next, was going to try single strand 12/2 grounded single strand wire as replacement for my extension cord but didn't have any on hand. Why does this pump require a control box at all? Could you detail its function or is it needed only to step down voltage from European electrical supplies? Can the pump be directly wired without a high risk of shorting it out? Will detail the wiring colors when I can, at work right now. Thanks in advance for any insight, RandyVMD

powered up the pump and was very impressed with the water flow, obtained a full 1 1/2" pipe of water at the top of a 25 foot rise and let this flow into a downspout collection basin that feeds to the pond.

First issue was that the European plug adapter immediately became hot and shorted out so I opened up the control box and replaced the pigtail plug with a standard US plug that I scavenged from a scrapped microwave, seemed to be equivalent guage. Set pump back in operation and it provided good flow for about 6 hours then the 20 amp breaker started tripping and shutting down the pump. Assuming my extension cord may be an issue, I replaced it with a 12 gauge cord and operated the pump again only to find that the control box wire leading to the circuit breaker continues to heat up within minutes of use and trips the breaker.

Not sure what to do next, was going to try single strand 12/2 grounded single strand wire as replacement for my extension cord but didn't have any on hand. Why does this pump require a control box at all? Could you detail its function or is it needed only to step down voltage from European electrical supplies? Can the pump be directly wired without a high risk of shorting it out? Will detail the wiring colors when I can, at work right now. Thanks in advance for any insight, RandyVMD