Jean-Sebastien Stoezel

New Member

Hello,

About 8 years ago I replaced an older Smith boiler with a new, well known brand. The old boiler was rated for 210kBTU, the new one is rated for 167kBTU.

Comparing the effectiveness of the 2 boilers, the old one used to put out a tremendous amount of heat, to the point where some rads were too hot to touch. It would hit the set point of 180F and would cycle.

The new boiler barely reached 150F, and that would be after a forced run of over 90min, by setting the thermostat to a high temperature value. In normal operation the boiler would require the bypass to be over half open with a slower circulator speed, otherwise it would not build up heat.

I was told this is because the piping around the boiler was 1" diameter, which throttled the boiler. The minimum pipe diameter recommended by the manufacturer of the boiler is 1-1/4". The low water temperature means that on cold days, the boiler cycles for 30min on/off.

Recently I had the same plumbing company replace the surrounding piping with 1-1/2" piping, which is 1/4" over the minimum piping. They also installed a larger circulator. This was to make sure rads on the 3rd floor of my house would get hot water, and also to speed up the round trip time of the water.

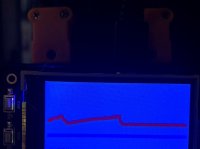

After this modification the boiler is operating slightly better. I can close the bypass to less than 1/4, though even after a forced run of 90min the water barely hits 160F, and once it reaches this temperature there is little to no temperature gain. The delta between supply and return is about 10F up until about 140F on the supply, and the delta goes down from there.

This boiler has been acting like this from the get go. I have had the plumbing company check twice with the manufacturer whether this boiler was the proper size, based on rad count, age of the house and insulation levels, number of stairs in the house. They are insuring me that this boiler is the correct size (they had initially installed the step down size and it was too small, and 167kBTU still is not the 210kBTU the old boiler used to be - which is a big gap even when you take into consideration the efficiency difference between old and new).

Every service technician from different heating companies I have hired to service this boiler keep setting the water temperature set point to 180F, though this temperature will never be reached, unless there is some sort of problem including circulator failure. Every single technician, including technicians from the company that installed the boiler have told me that if the boiler cannot reach 180F it has to be undersized. Even the manufacturer website recommends and average water setpoint of 180F, and increase this value on cold days to 210F.

And so, if the boiler is properly sized (dixit the manufacturer and the installer), is it that this boiler has been defective from the get go?

Where does the 180F water temperature value come from? What is a reasonable amount of time that this temperature value should be reached, and from what starting water temperature? How much bypass flow should be used to achieve this temperature?

Thank you for your help.

About 8 years ago I replaced an older Smith boiler with a new, well known brand. The old boiler was rated for 210kBTU, the new one is rated for 167kBTU.

Comparing the effectiveness of the 2 boilers, the old one used to put out a tremendous amount of heat, to the point where some rads were too hot to touch. It would hit the set point of 180F and would cycle.

The new boiler barely reached 150F, and that would be after a forced run of over 90min, by setting the thermostat to a high temperature value. In normal operation the boiler would require the bypass to be over half open with a slower circulator speed, otherwise it would not build up heat.

I was told this is because the piping around the boiler was 1" diameter, which throttled the boiler. The minimum pipe diameter recommended by the manufacturer of the boiler is 1-1/4". The low water temperature means that on cold days, the boiler cycles for 30min on/off.

Recently I had the same plumbing company replace the surrounding piping with 1-1/2" piping, which is 1/4" over the minimum piping. They also installed a larger circulator. This was to make sure rads on the 3rd floor of my house would get hot water, and also to speed up the round trip time of the water.

After this modification the boiler is operating slightly better. I can close the bypass to less than 1/4, though even after a forced run of 90min the water barely hits 160F, and once it reaches this temperature there is little to no temperature gain. The delta between supply and return is about 10F up until about 140F on the supply, and the delta goes down from there.

This boiler has been acting like this from the get go. I have had the plumbing company check twice with the manufacturer whether this boiler was the proper size, based on rad count, age of the house and insulation levels, number of stairs in the house. They are insuring me that this boiler is the correct size (they had initially installed the step down size and it was too small, and 167kBTU still is not the 210kBTU the old boiler used to be - which is a big gap even when you take into consideration the efficiency difference between old and new).

Every service technician from different heating companies I have hired to service this boiler keep setting the water temperature set point to 180F, though this temperature will never be reached, unless there is some sort of problem including circulator failure. Every single technician, including technicians from the company that installed the boiler have told me that if the boiler cannot reach 180F it has to be undersized. Even the manufacturer website recommends and average water setpoint of 180F, and increase this value on cold days to 210F.

And so, if the boiler is properly sized (dixit the manufacturer and the installer), is it that this boiler has been defective from the get go?

Where does the 180F water temperature value come from? What is a reasonable amount of time that this temperature value should be reached, and from what starting water temperature? How much bypass flow should be used to achieve this temperature?

Thank you for your help.