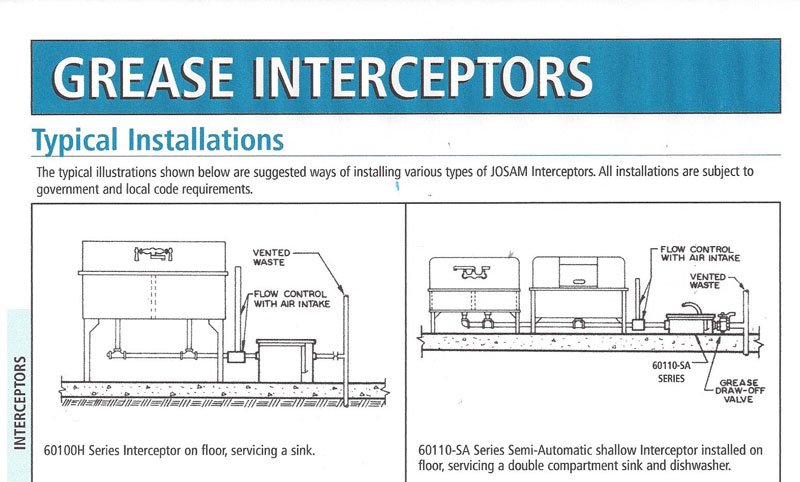

I haven't seen a mention of what type of grease interceptor is needed. Manual, semi-automatic or automatic. Sometimes this can be costly if the required interceptor isn't confirmed by the inspecting authority. Even when replacing an existing interceptor, updated codes may require a different one.

When referring to the code excerpt that related to air gaps, the "equipment" that is mentioned does not include sinks. It translates to equipment such as dish washers, glass sterilizers and the like.

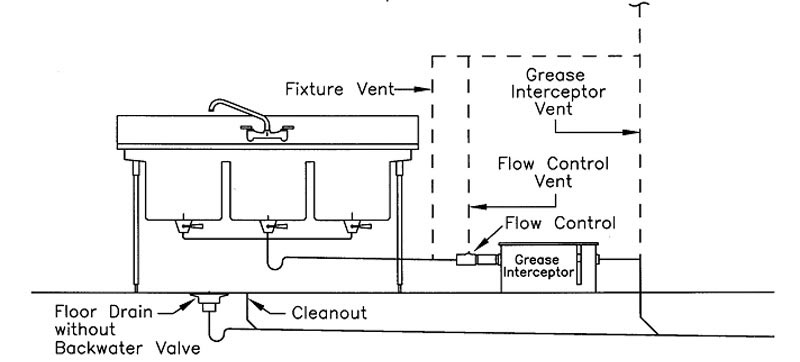

Most standard installations are as follows for three compartment sinks.

2" p-trap on each compartment followed by a vent for each trap.

Diffuser to control flow and then a clean out before the interceptor inlet. The diffuser will have it's own vent attachment (usually 3/4" or 1").

After the interceptor there will be another vent. This one works together with the diffuser vent to prevent vapor lock in the interceptor.

No AAVs or studor vents are to be used on the installation for any vents.

If a semi-automatic or automatic interceptor is installed then a valve will be installed on the interceptor outlet.

It's also important to have the grease interceptor properly sized for the total volume of the three compartment sink. That also has not been mentioned yet, so I thought it may be important if food or plumbing inspections are pending.

If this is a new restaurant installation, keep in mind that any prep sinks with disposals attached may be required to discharge into the grease trap as well. Some of the plumbing codes refer to the IMC for this type of arrangement in restaurants.

Since the introduction of the IPC and UPC across the US, double-trapping has become one of the most misunderstood subjects because of the interpretation of the modern definition and the examples given by the IPC/UPC, even though avoiding the practice has been observed for over a hundred years. If installed as I described above, double-trapping will not be an issue.