KiviP

Member

Hi everyone,

I am planning on converting the bathroom vanity to a double sink during our bathroom remodel.

Mu question is regarding the setup I have in mind.

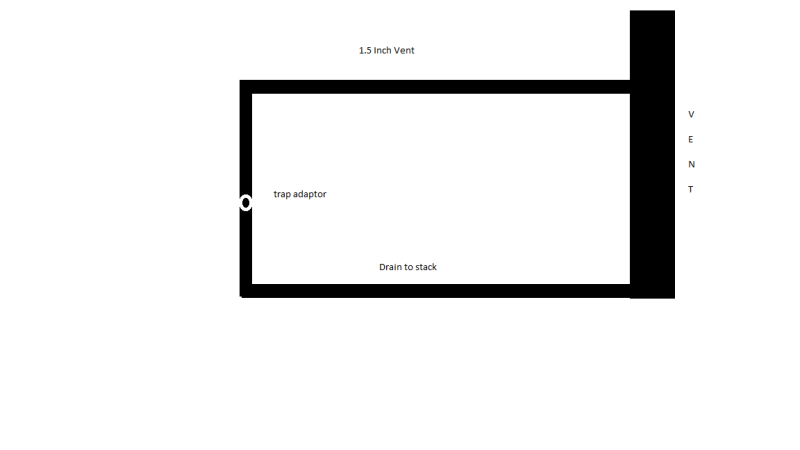

This is what I have

I am planning on cutting into the pipe above and below the trap arm indicated by the red line (shown below). Pipes are 1.5 steel. Now would it be ok to use a double sanitary tee or should i use a double wye (marked as 1)

I am planning on using two 45s on the bends to the trap adaptors on each run (indicated by 2 and 3).

Last, pipe goes between the studs and I dont want to cut into them. I am planning on offsetting them and bringing them by usinc the 45s so they come out of the studs bays and into the open space. Is this a reasonable design?

I am planning on converting the bathroom vanity to a double sink during our bathroom remodel.

Mu question is regarding the setup I have in mind.

This is what I have

I am planning on cutting into the pipe above and below the trap arm indicated by the red line (shown below). Pipes are 1.5 steel. Now would it be ok to use a double sanitary tee or should i use a double wye (marked as 1)

I am planning on using two 45s on the bends to the trap adaptors on each run (indicated by 2 and 3).

Last, pipe goes between the studs and I dont want to cut into them. I am planning on offsetting them and bringing them by usinc the 45s so they come out of the studs bays and into the open space. Is this a reasonable design?

Last edited: