Hi guys, longtime lurker, first time poster.

I was looking for DIY options to resolve my nasty iron and hydrogen sulfide issue (see headline). Everything I read online makes it seem like this much iron is going to be a constant battle of unclogging whatever unit I get, but I'm thinking the smart folks here can steer me in the right direction.

- 5 Person Home with occasional overnight guests for the kids

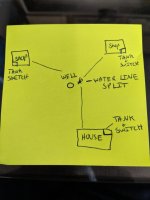

- Well pump can do 15GPM currently, but I could oversize if need be. Well pump feeds my business shop (minimal water use outside of toilets and washing hands), a hanger shop (very minimal use), and our house (most usage). I'm looking to put an iron removal unit in each of the 3 locations.

Question 1) Hydrogen peroxide system or Air injection?

Question 2) If air injection is acceptable, does anyone have experience with these AFW Platinum units?

Question 3) If peroxide is acceptable, does anyone have experience with these inFusion Units?

Question 4) What else am I not considering with my current situation?

Thanks in advance everyone.

I was looking for DIY options to resolve my nasty iron and hydrogen sulfide issue (see headline). Everything I read online makes it seem like this much iron is going to be a constant battle of unclogging whatever unit I get, but I'm thinking the smart folks here can steer me in the right direction.

- 5 Person Home with occasional overnight guests for the kids

- Well pump can do 15GPM currently, but I could oversize if need be. Well pump feeds my business shop (minimal water use outside of toilets and washing hands), a hanger shop (very minimal use), and our house (most usage). I'm looking to put an iron removal unit in each of the 3 locations.

Question 1) Hydrogen peroxide system or Air injection?

Question 2) If air injection is acceptable, does anyone have experience with these AFW Platinum units?

Question 3) If peroxide is acceptable, does anyone have experience with these inFusion Units?

Question 4) What else am I not considering with my current situation?

Thanks in advance everyone.