Thanks, I think I understood most of that. I was really wondering whether it would be better to set a larger allowed delta-T before the pump kicks back up again, and have the water heater temp set higher(which might require the use of a mixing valve, splitting the return from the radiant heating loops between the heater and the mixing valve)....or if it would be better to set a more narrow delta-T on the pump and keep the hot water heater turned down.

Describe the type of radiant floor (slab? suspended tube? suspended tube with convection fins? staple-up? staple up with plates?), and how many BTU/hr per square foot the floor needs to deliver. The particulars make a huge difference as to what the water temperatures need to be.

From what you said...it seems like it would be the latter as far as efficiency goes, even though(as far as I understand it) that might mean the boiler is on more often. And that would forgo that shouldn't require a mixing valve.

With a mixing valve the flow through the tankless can become too low to keep the flame going- this really has to be designed, not hacked. A high mass buffer tank can take high temp water out of the tankless at any arbirtary flow rate and still deliver cooler water to the radiation, if necessary.

"Open radiant heating systems have pathogen risks due to stagnation at tepid temperatures, and are disallowed in some states for that reason."

I have worried about that as well, so I guess I just need to make sure I don't go

too low in pursuit of cost savings....what do you think a good temperature setting would be? If it matters it's a 3 zone system, largest loop is just under 300ft, ~750ft total, I doubt I will often(probably never) have more than 2 zones going at the same time....along with a

groundfos alpha 2 pump, possibly using the autoadapt feature(we will see how that goes).

It's better to install a plate type heat exchanger (rated for potable water) to isolate the potable water from the heating system loop and get rid of the problem than it is to run at some high temperature in the hopes that nothing bad will happen. Unless the water in the heating loops are reliably below 75F in the summer and over 125F in the winter you're just asking for bad things to happen. Letting even one zone stagnate all summer can contaminate the rest of the system if something starts growing, so in the summer every inch of pipe has to have flow at some minimum duty cycle to stay reasonably clean. (The minimum duty cycle in summer to avoid problems related to stagnation is enshrined in code in Massachusetts, where the pathogen risk isn't even as high as as it is in Georgia due to the lower incoming water temps.)

Open systems are more trouble than they're worth, especially in locations with warm enough summers (and water temperatures) to require. substantial air conditioning. You can maybe get away with it most of the time in, say, Edmonton Alberta, but it's riskier south of the 48th parallel, riskier still south of the Mason-Dixon.

Seriously, isolating the heating system costs you at most one pump, the heat exchanger and an expansion tank for the heating side, and it allows you to set the flows on the heating side independently of the flow on the potable side. This works just fine with a tank"less", where it's labeled "Tank":

But whether this exact configuration works with the temperature requirements of your radiation remains to be seen. You have to do at least

some of the basic design math, starting with:

Heat loss calculations, broken down zone-by-zone (Manual-J or I=B=R method works, but not the typical crummy online calculators.)

Available square footage of active radiant floor, to determine the floor temperature needed to support the calculated load.

The radiant floor type, and floor stackup, which will determine the water temperature needed to deliver the calculated floor temperature or BTU/hr per square foot.

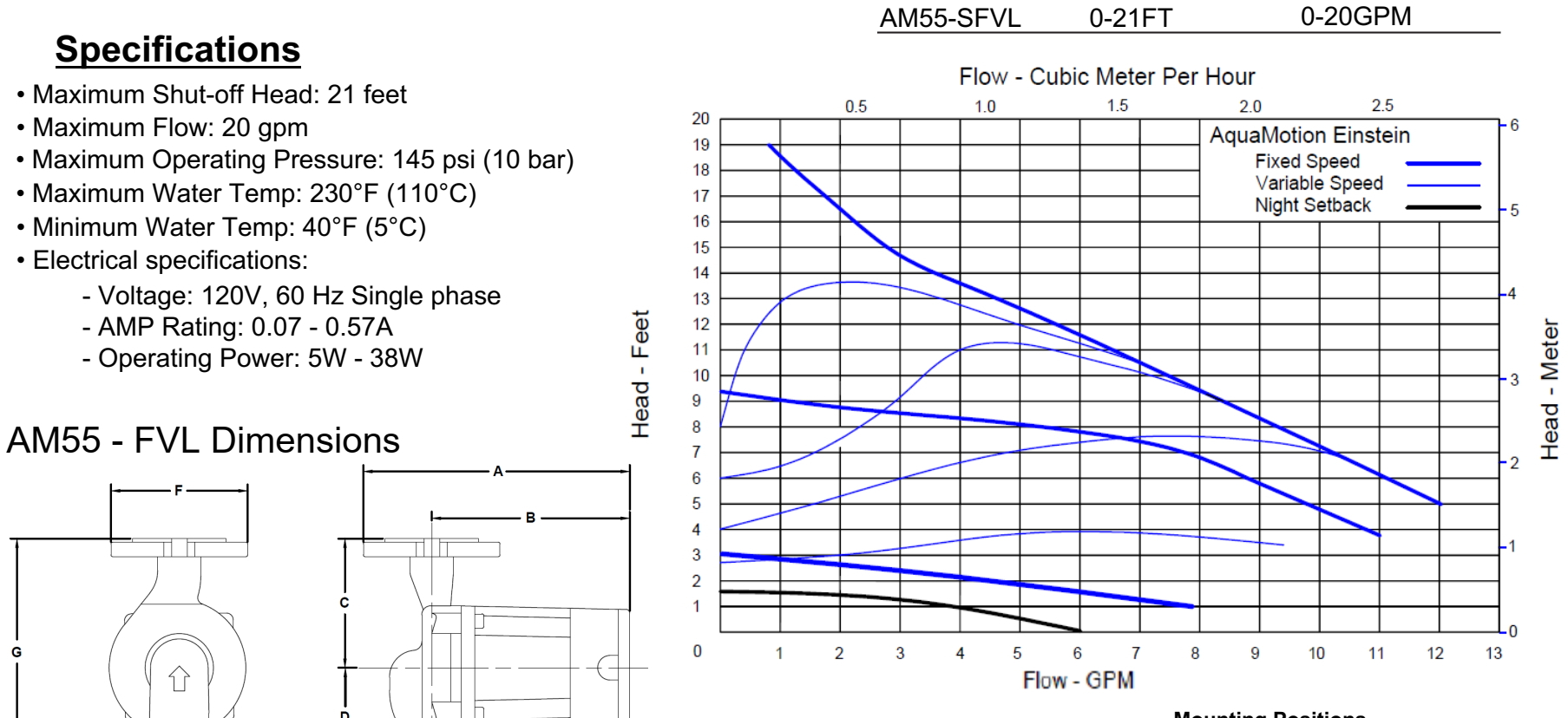

While it's a great pump, the minimum flow rate of the

Alpha 2 isn't as low as the Taco

VR1816 or Aquamotion

AM55 "Einstein" (which I had to use in "Night Setback" mode to avoid over pumping one of my micro-zones) and may end up over pumping either the tankless or the system, depending on how you have it configured. Don't count on "Autoadapt" avoid having to actually design something (at least to the napkin-math level.)

With the Alpha 2 in Autoadapt mode if there's less than 4 feet of pumping head @ 2gpm some smaller zone the flow rate is going to be potentially higher than what you want or need.

^^Alpha 2 pump curves

^^ Aquamotion AM55 pump curves

^^VR1816 pump curves