I'm trying to make my house more energy efficient. I was crawling around one of my crawl spaces (I have 2) and have decided to make it a encapsulated crawl. I'm going to put down 6 mil vapor barrier on the ground and insulate the concrete walls. Only the kitchen lies above the crawlspace. There are 2 registers in the kitchen. There is also a cold air return in the kitchen that I'm going to remove and cap off (per code)

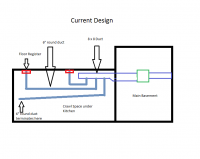

An old friend of mine who did sheet metal told me that, with round duct, every time the duct makes a 90 degree turn, you loose a lot of efficiency. Looking at the current duct design under the crawl, it looks like I may be able to re-do it and make it a little bit more efficient. It's basically an 8 x 8 duct that has three 6" round ducts coming from it. 2 go to the registers (both of those have at least two 90 degree elbows) and the third duct just terminates at the end of the crawlspace. The third duct looked like it, at one time, went to a register. I say this because it still has a boot attached to it and there is a covered hole above it in the floor (where the boot would have been). Now that boot just hangs there.

I had three different ideas:

1. Leave it alone... Maybe I'm making a mountain out of a mole hill and doing this won't really changing anything. I will add dampers (there are none on any branch in my house) so I can control the amount of air going to each register and also how much air is going into the crawl.

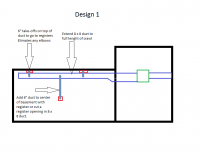

2. Extend the 8 x 8 duct the whole length of the crawl (extra 10' or so) and add take-offs from the top of the duct to each register. It would be a straight shot from the top of the duct to the register boots and would eliminate any elbows in the duct work. I would add either a register on the 8 x 8 duct or run a 6" round duct to the center of the crawl to provide the conditioning. I would then adjust the amount of air going into the crawl via a dampener.

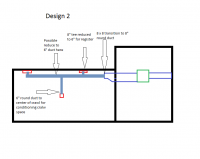

3. Transition the 8 x 8 duct to a 8" round duct. Run "tees" off the round duct to each register (I'd have to reduce from 8" to 6" from the tee as the boot is a 6"). Also run a tee so I can run a round duct to center of crawl for conditioned air.

I've read that I should have some air (heat or a/c) go into the crawlspace if I encapsulate it, but it doesn't need much.

I attached some photos of the current system and drawings of what the current design looks like and drawings of idea 2 and 3 above.

Again... maybe I'm making a mountain out of a mole hill but I like learning about this stuff and with how much propane was last year, any help would be greatly appreciated.

An old friend of mine who did sheet metal told me that, with round duct, every time the duct makes a 90 degree turn, you loose a lot of efficiency. Looking at the current duct design under the crawl, it looks like I may be able to re-do it and make it a little bit more efficient. It's basically an 8 x 8 duct that has three 6" round ducts coming from it. 2 go to the registers (both of those have at least two 90 degree elbows) and the third duct just terminates at the end of the crawlspace. The third duct looked like it, at one time, went to a register. I say this because it still has a boot attached to it and there is a covered hole above it in the floor (where the boot would have been). Now that boot just hangs there.

I had three different ideas:

1. Leave it alone... Maybe I'm making a mountain out of a mole hill and doing this won't really changing anything. I will add dampers (there are none on any branch in my house) so I can control the amount of air going to each register and also how much air is going into the crawl.

2. Extend the 8 x 8 duct the whole length of the crawl (extra 10' or so) and add take-offs from the top of the duct to each register. It would be a straight shot from the top of the duct to the register boots and would eliminate any elbows in the duct work. I would add either a register on the 8 x 8 duct or run a 6" round duct to the center of the crawl to provide the conditioning. I would then adjust the amount of air going into the crawl via a dampener.

3. Transition the 8 x 8 duct to a 8" round duct. Run "tees" off the round duct to each register (I'd have to reduce from 8" to 6" from the tee as the boot is a 6"). Also run a tee so I can run a round duct to center of crawl for conditioned air.

I've read that I should have some air (heat or a/c) go into the crawlspace if I encapsulate it, but it doesn't need much.

I attached some photos of the current system and drawings of what the current design looks like and drawings of idea 2 and 3 above.

Again... maybe I'm making a mountain out of a mole hill but I like learning about this stuff and with how much propane was last year, any help would be greatly appreciated.