BPIAuditLongIsland

New Member

I am hoping with the knowledge on here I can find someone on long island who can do the system design for me, or help me through this online.

Over the next few years I want to completely change over my home from an energy wasting nightmare to an energy efficient comfortable home. Due to budget constraints and logistics, I also need to do this in pieces.

Current home:

1511 sq ft home built in 1927with flat roof. stucco exterior 1 pipe steam heating system with 1 zone of slant fin and a standalone 40gal hot water.

1238 sq ft of that is balloon frame 9' ceilings with no insulation over a full basement with no insulation again 9' ceilings

273 sq of that is platform frame with R-13

Finished home ~2500 sq ft putting 2nd story on main portion of home. Insulated all with spray foam.

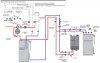

Lochnivar WHN055 boiler with a 60-80 gallon indirect tank, 30-80 gallon boiler buddy, feeding mix of cast iron radiators, cast iron baseboard, and radiant heat. Total of 5-7 zones

My friend is a plumber, and will be assisting with the install, but unfortunately he does not have a clue as to how to properly install a condensing system, nor do I know of any local plumbers who do either. I see 5 heating systems a week due to my job, and have yet to meet a heating contractor that does not install a system 2-5 times to large due to "fear of callbacks".

I would like to start off with installing the Lochnivar WHN055 boiler with a 60-80 gallon indirect tank, 30-80 gallon boiler buddy, onto 1 zone of slant fin, 1 cast iron radiator I will be installing in the basement, and the 1 indirect zone to start. My current hot water heater is on its way out, and i need to add a heating zone to the basement, as well as i need to get this slant fin zone off of the steam boiler.

Thanks in advance

Over the next few years I want to completely change over my home from an energy wasting nightmare to an energy efficient comfortable home. Due to budget constraints and logistics, I also need to do this in pieces.

Current home:

1511 sq ft home built in 1927with flat roof. stucco exterior 1 pipe steam heating system with 1 zone of slant fin and a standalone 40gal hot water.

1238 sq ft of that is balloon frame 9' ceilings with no insulation over a full basement with no insulation again 9' ceilings

273 sq of that is platform frame with R-13

Finished home ~2500 sq ft putting 2nd story on main portion of home. Insulated all with spray foam.

Lochnivar WHN055 boiler with a 60-80 gallon indirect tank, 30-80 gallon boiler buddy, feeding mix of cast iron radiators, cast iron baseboard, and radiant heat. Total of 5-7 zones

My friend is a plumber, and will be assisting with the install, but unfortunately he does not have a clue as to how to properly install a condensing system, nor do I know of any local plumbers who do either. I see 5 heating systems a week due to my job, and have yet to meet a heating contractor that does not install a system 2-5 times to large due to "fear of callbacks".

I would like to start off with installing the Lochnivar WHN055 boiler with a 60-80 gallon indirect tank, 30-80 gallon boiler buddy, onto 1 zone of slant fin, 1 cast iron radiator I will be installing in the basement, and the 1 indirect zone to start. My current hot water heater is on its way out, and i need to add a heating zone to the basement, as well as i need to get this slant fin zone off of the steam boiler.

Thanks in advance