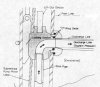

What do I have in my well pit? The flange is about 4 or 5 inches off of the floor. One of the bolt holes of the flange is being used to run the two wires to the Sta-rite 170 ft down in a 190ft 4-inch casing. The well used to have a 3-wire pump, but it was replaced with a 2-wire.

I think that the steel pipe through the pit wall was turned into a conduit to pass the blue pipe into the basement.

What is under the flange, do you think? Is that flange carrying the weight of the pump etc, or is just covering something else? White stuff at base of flange is some remaining soap. I washed things from up top before the picture. I am reaching in through the 18.5 inch square opening at maybe 1/2 inch above ground level.

I think the bolts are 7/16-20. I know that is a standard size. I measured by threading a 7/16 dowel into a bolt hole, and examining the marks. The flange says "LA GRANGE IL, USA" on the right part of the flange as viewed in the picture. I have not identified other writing on the rusty flange.

There was a fragment of the blue plastic piping on the floor of the pit. I don't remember where I put it, but it will show up.

I understand a well pit could not be built today. If I were to get mine changed out to a pitless with the casing extended 12 inches above ground, and if the basement is 18 feet away, what would I budget for that job, do you think? If I did it, I expect I would wait until I had other well work needed.

I think that the steel pipe through the pit wall was turned into a conduit to pass the blue pipe into the basement.

What is under the flange, do you think? Is that flange carrying the weight of the pump etc, or is just covering something else? White stuff at base of flange is some remaining soap. I washed things from up top before the picture. I am reaching in through the 18.5 inch square opening at maybe 1/2 inch above ground level.

I think the bolts are 7/16-20. I know that is a standard size. I measured by threading a 7/16 dowel into a bolt hole, and examining the marks. The flange says "LA GRANGE IL, USA" on the right part of the flange as viewed in the picture. I have not identified other writing on the rusty flange.

There was a fragment of the blue plastic piping on the floor of the pit. I don't remember where I put it, but it will show up.

I understand a well pit could not be built today. If I were to get mine changed out to a pitless with the casing extended 12 inches above ground, and if the basement is 18 feet away, what would I budget for that job, do you think? If I did it, I expect I would wait until I had other well work needed.